A device for preparing tetravalent uranium by electrolytic reduction

A tetravalent uranium and electrolytic cell technology, applied in electrolysis process, electrolytic components, cells, etc., can solve the problems of low yield of tetravalent uranium, complex equipment, high cost, etc., to avoid partial oxidation, convenient operation and maintenance, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

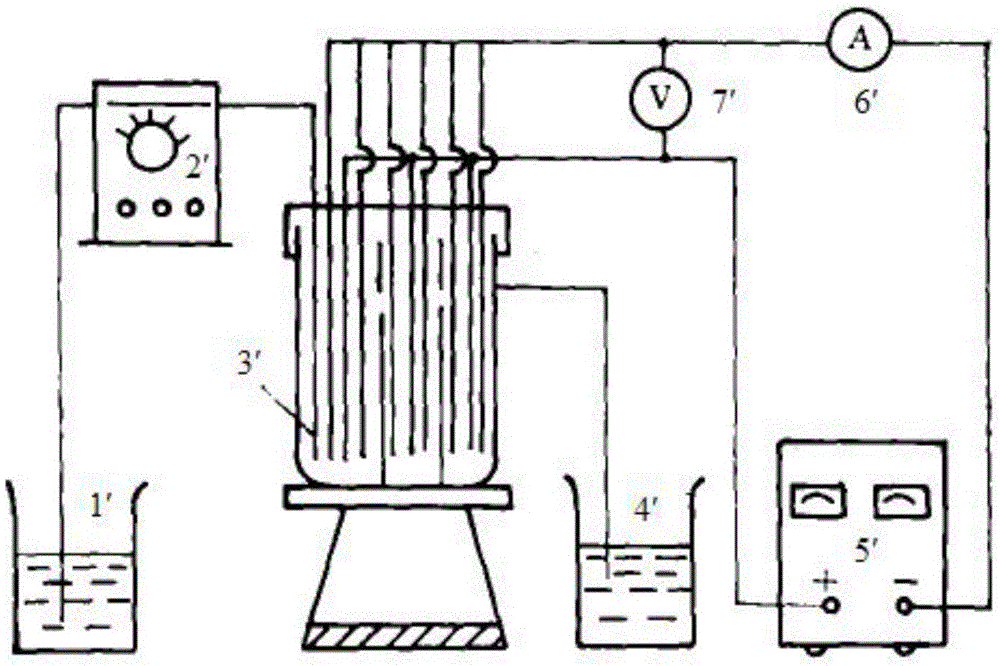

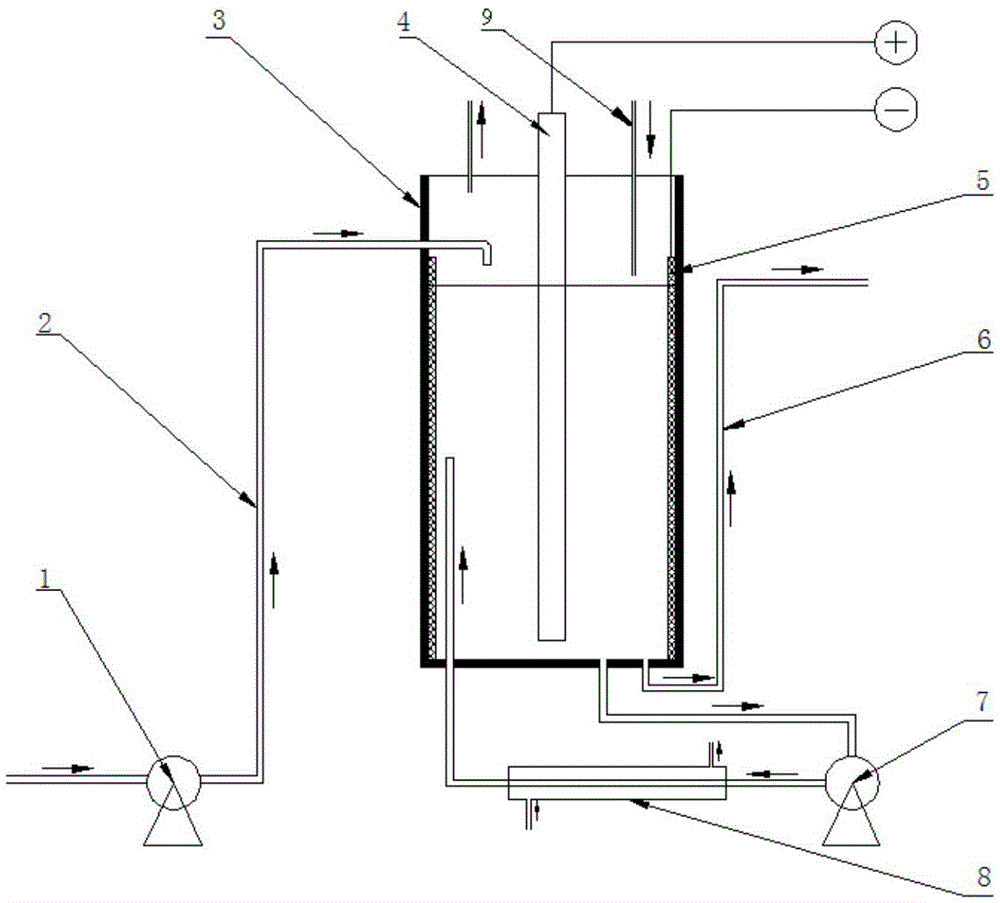

[0031] A device for preparing tetravalent uranium by electrolytic reduction, comprising an electrolytic cell body 3 whose inner wall is insulated with rubber, an anode platinum-coated titanium rod 4 and a cathode titanium mesh 5. The side wall of the electrolytic cell body 3 is cylindrical in shape, and its effective The volume is 31.5L, the cathode titanium mesh 5 is cylindrical, the anode platinum-coated titanium rod 4 is located on the axis of the cylindrical cathode titanium mesh 5, the cathode titanium mesh 5 and the anode platinum-coated titanium rod 4 The surface area ratio is 16.5:1.

[0032] The device for preparing tetravalent uranium by electrolytic reduction also includes a cooling device, which is composed of a circulation pump 7, a casing cooler 8 and pipelines, and the electrolyte drawn from the bottom of the electrolytic cell body 3 is cooled by the cooling device and then returned to the electrolysis Tank 3 for cooling purpose.

[0033] The device for prepari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com