Non flame-retardant glossy elastomer material for headphone cable and preparation method of elastomer material

An elastomer material, non-flame retardant technology, applied in the field of polymer elastomer materials, can solve the problems of poor processing performance and high price of TPU, and achieve the effect of broad market application prospects and increased material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

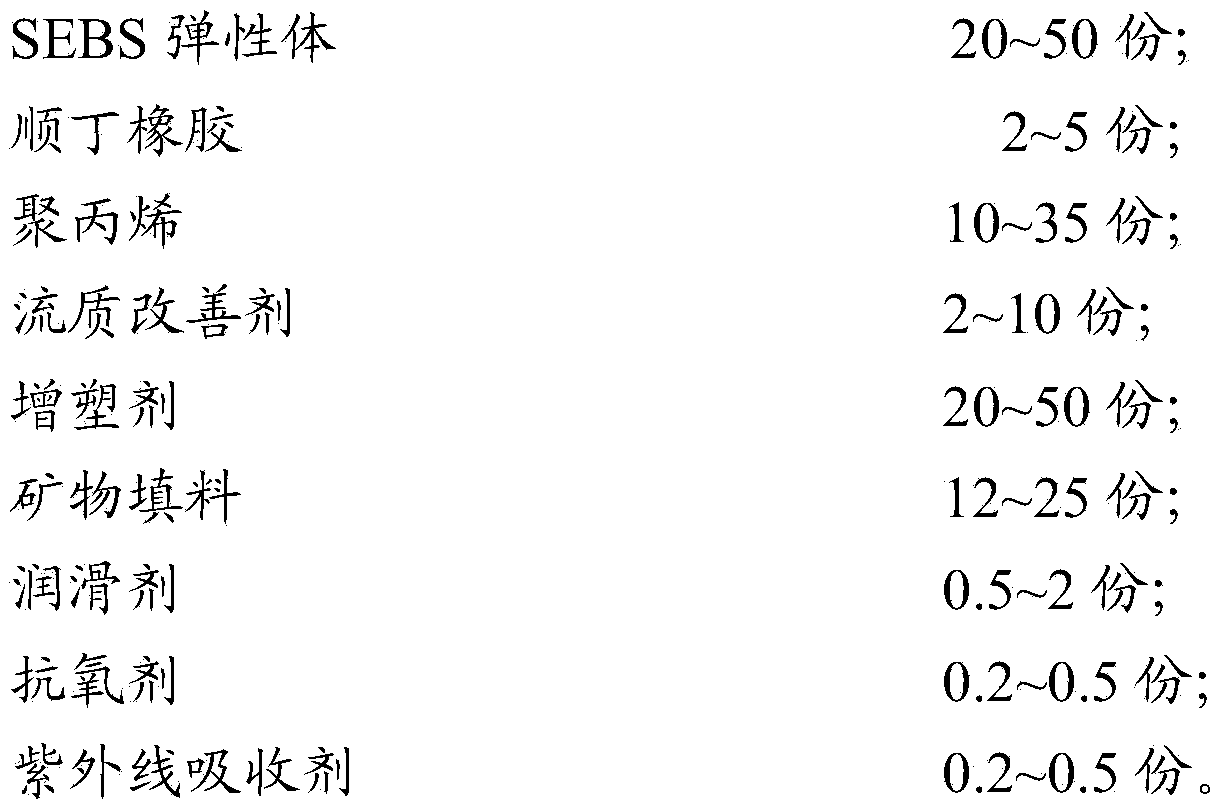

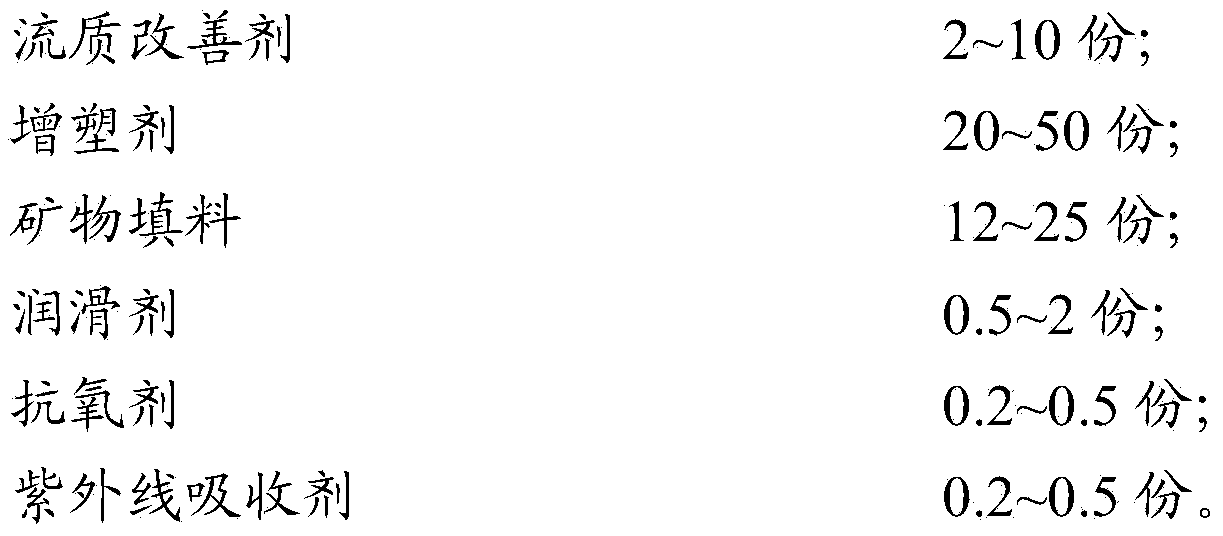

Method used

Image

Examples

Embodiment 1

[0029]

[0030]

[0031] The preparation method is as follows:

[0032] First, 25 parts of SEBS elastomer with a weight-average molecular weight of 180,000 (optional grades are: Japan Kuraray 4044, American Kraton 1654, Taiwan Taiwan Rubber 6154, Taiwan Li Changrong 9551, and this example is preferably Japan Kuraray 4044), 3 parts Butadiene rubber, 30 parts of polypropylene, and 5 parts of fluid quality improver are put into the high-speed mixer, and the high-speed mixer is turned on to mix the input materials at high speed. During the mixing process, 40 parts of plasticizer are put in from the upper port, and after 8 minutes of high-speed mixing , and then put 20 parts of mineral filler, 0.5 part of lubricant, 0.3 part of antioxidant, 0.2 part of ultraviolet absorber into the high-speed mixer, high-speed mixing, and the discharge is granulated by a twin-screw extruder to obtain a non-flame-retardant bright surface elasticity Body earphone cable material. The temperatur...

Embodiment 2

[0034]

[0035] The preparation method is as follows:

[0036] First, 25 parts of SEBS elastomer with a weight-average molecular weight of 120,000 (optional grades are: Japan Kuraray 4033, American Kraton 1650, Taiwan Taiwan Rubber 6150, Taiwan Li Changrong 9550, and this example is preferably Taiwan Taiwan Rubber 6150), 3 parts Butadiene rubber, 30 parts of polypropylene, and 5 parts of fluid quality improver are put into the high-speed mixer, and the high-speed mixer is turned on to mix the input materials at high speed. During the mixing process, 40 parts of plasticizer are put in from the upper port, and after 8 minutes of high-speed mixing , and then put 20 parts of mineral filler, 0.5 part of lubricant, 0.3 part of antioxidant, 0.2 part of ultraviolet absorber into the high-speed mixer, high-speed mixing, and the discharge is granulated by a twin-screw extruder to obtain a non-flame-retardant bright surface elasticity Body earphone cable material. The temperature set...

Embodiment 3

[0038]

[0039] The preparation method is as follows:

[0040]First, 30 parts of SEBS elastomer with a weight-average molecular weight of 120,000 (optional grades are: Japan Kuraray 4033, American Kraton 1650, Taiwan TSRC 6150, Taiwan Li Changrong 9550, and Taiwan TSRC 6150 is preferred in this example), 3 parts Butadiene rubber, 25 parts of polypropylene, and 5 parts of fluid quality improver are put into the high-speed mixer, and the high-speed mixer is turned on to mix the input materials at high speed. During the mixing process, 30 parts of plasticizer are put in from the upper port, and after 8 minutes of high-speed mixing , and then put 20 parts of mineral filler, 0.5 part of lubricant, 0.3 part of antioxidant, 0.2 part of ultraviolet absorber into the high-speed mixer, high-speed mixing, and the discharge is granulated by a twin-screw extruder to obtain a non-flame-retardant bright surface elasticity Body earphone cable material. The temperature setting of each zone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com