Fully-automatic plasticizing rubber powder premixer

A technology for plasticizing rubber powder and premixer, which is applied in the direction of plastic recycling and recycling technology, and can solve the problems of waste of resources, difficulty in fully homogenizing, and low quality of reclaimed rubber powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

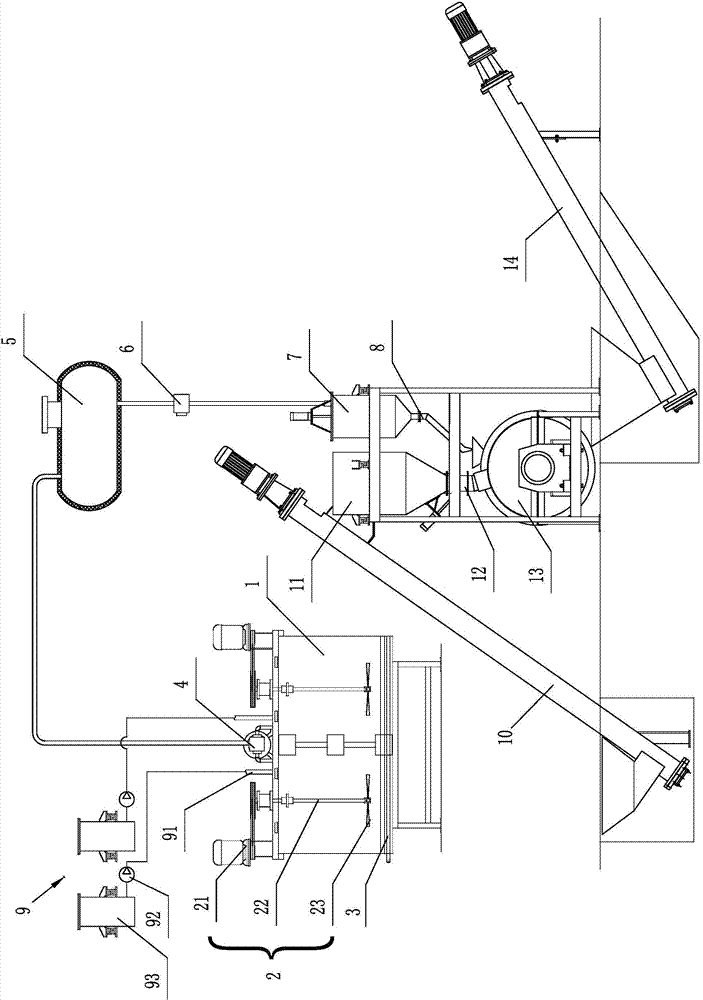

[0019] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

[0020] Such as figure 1 As shown, the fully automatic plasticized rubber powder premixer includes:

[0021] The auxiliary agent supply device includes an auxiliary agent homogenization box 1; an auxiliary agent stirring device 2 is installed in the auxiliary agent homogenization box 1. In this embodiment, the auxiliary agent stirring device 2 includes an electric motor 21, the electric motor 21 A stirring shaft 22 is dynamically connected by a speed changer, and a stirring blade 23 is provided at the lower end of the stirring shaft 22; an assistant heating device 3 is also installed in the assistant homogenizing box 1. In this embodiment, the assistant heating The device 3 is an electric heating tube. Of course, a heating medium heating tube with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com