A horizontal feeding auger

A horizontal feeding, part of the technology, applied in the field of feeding equipment, can solve the problems of feeding performance limitations, no equipment cleaning structure, difficult to clean materials, etc., achieve short residence time, strengthen axial fixation, and ensure smooth work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

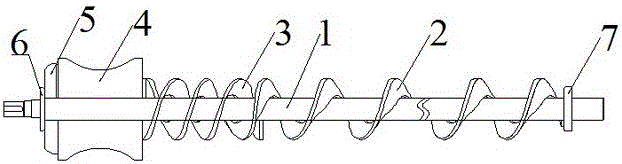

[0022] Such as figure 1 As shown, a horizontal feeding auger includes an auger shaft 1, an auger blade 2 welded on the auger shaft 1, a short blade 3 of the auger, an anti-blade 5 of the auger, and a long scraper 4; The short blade 3 and a part of the auger blade 2 form a double helix structure; the ratio of the length of the auger short blade 3 to the auger blade 2 along the axial direction of the auger shaft 1 is 1:5; the long scraper 4 is fixed on the auger shaft 1 One end, and one end of the long scraper 4 is connected with the double helix structure formed by the short blade 3 of the auger and the blade 2 of the auger, and the other end is fixed with one end of the anti-blade 5 of the auger; dust cover 6, and the dust cover 6 is fixed on the other end of the auger anti-blade 5.

[0023] In addition, both the auger blade 2 and the auger short blade 3 are left-handed, and the auger anti-blade 5 is right-handed. The other end of the auger shaft 1 is also provided with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com