Gold base alloy casting blank melting and casting integrated device and utilization method thereof

A gold-based alloy and casting billet technology, applied in the field of material processing equipment, can solve problems such as limited effect, and achieve the effects of reducing the possibility of casting cracks, reducing the number of oxide inclusions, and reducing the number of oxide inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

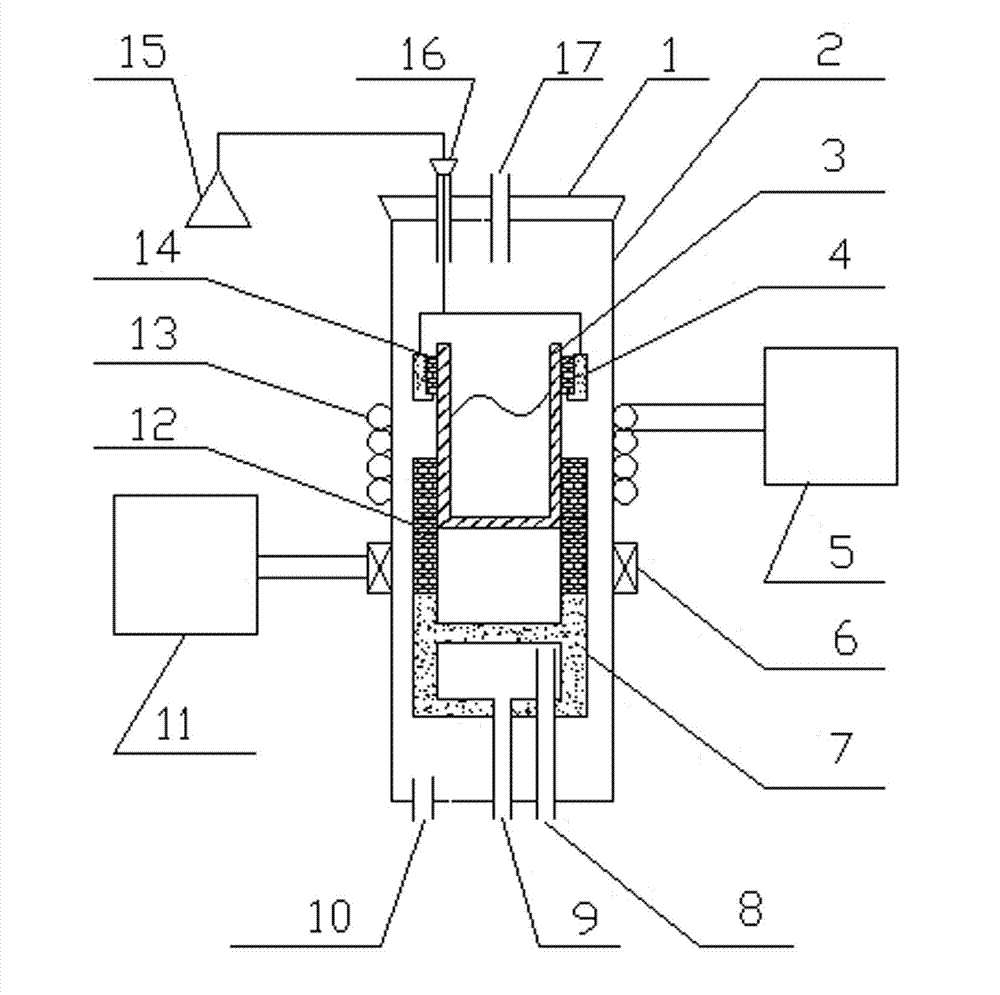

[0054] The structure of the melting and casting integrated device for gold-based alloy billet is as follows: figure 1 As shown, it includes a crucible 3, a refractory cylinder 12, a cooling base 7, an outer cylinder 2, a heating induction coil 13 and a magnetic stirring device 6;

[0055] The crucible 3, the refractory material cylinder 12 and the cooling base 7 are arranged inside the outer cylinder 2, and the outer cylinder 2 is provided with a heating induction coil 13 and a magnetic stirring device 6; the heating induction coil 13 is connected to the high-frequency power supply 5 through wires;

[0056] The cooling base 7 is provided with a cavity, and the cooling base 7 is provided with a cooling medium inlet 9 and a cooling medium outlet 8 respectively connecting the cavity with the outside of the outer cylinder 2, and the outer cylinder 2 is also provided with an air inlet 10 and an outlet. Air port 17;

[0057] A clamp 4 is set on the outer wall of the crucible 3, and...

Embodiment 2

[0080] The integrated melting and casting device structure of the gold-based alloy billet is the same as that of Embodiment 1, the difference is that:

[0081] 1. The lifting rod is inserted into the socket, but not connected to the socket;

[0082] 2. The magnetic stirring device is a permanent magnet stirring device, and the permanent magnet stirring device is arranged at the bottom of the outer cylinder;

[0083] 3. The cooling base 7 is made of heat-resistant stainless steel;

[0084] Using method is the same as embodiment 1, and difference is:

[0085] 1. Apply current to the heating induction coil through a high-frequency power supply to generate a magnetic field, and heat the metal material in the crucible through the magnetic field; in order to prevent splashing, first preheat Al, Y, In, Co, Cu and Zn to 200°C ; After the Au in the crucible is melted, Al, Y, In, Co, Cu and Zn are pressed into the Au melt through the feeding port with a feeding rod to carry out the al...

Embodiment 3

[0092] The structure of the melting and casting integrated device for the gold-based alloy billet is the same as that of Embodiment 1, except that the cooling base 7 is made of heat-resistant stainless steel;

[0093] Using method is the same as embodiment 1, and difference is:

[0094]1. Introduce reducing gas into the outer cylinder through the air inlet, and the reducing gas is discharged from the outlet, so that the air in the outer cylinder is discharged and filled with flowing reducing gas; the reducing gas is hydrogen; When hydrogen gas is introduced from the mouth to the outer cylinder, the hydrogen gas will be ignited and burned after being discharged from the gas outlet;

[0095] 2. Apply current to the heating induction coil through a high-frequency power supply to generate a magnetic field, and heat the metal material in the crucible through the magnetic field; in order to prevent splashing, first preheat Al, Y, In, Co, Cu and Zn to 200°C ; After the Au in the cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com