Lining Process of Ductile Iron Pipe

A technology of ductile iron pipes and centrifugal nodular cast iron, which is applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of easy falling off and impact of the lining layer, and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The ductile iron pipe lining process, the specific steps are:

[0039] In the first step, the inner wall of the rough pipe of the ductile iron pipe is ground and shot blasted. Among them, after grinding, use the dust suction device to absorb the dust generated by grinding into the storage container for collection. The grinding standard is to make the inner wall of the pipe smooth without burrs and pits, so that the inner surface of the cast rough pipe meets the requirements of the inner wall of the lining and is smooth. The polished pipe is shot blasted on the inner wall. The standard is to remove the floating dust, rust (powder) and oxide layer after grinding to meet the requirements of the inner lining. In this embodiment, the blank pipe material is a water-cooled metal type centrifugal ductile iron pipe.

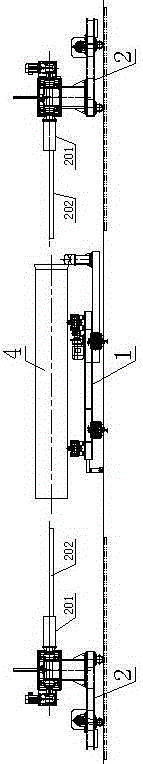

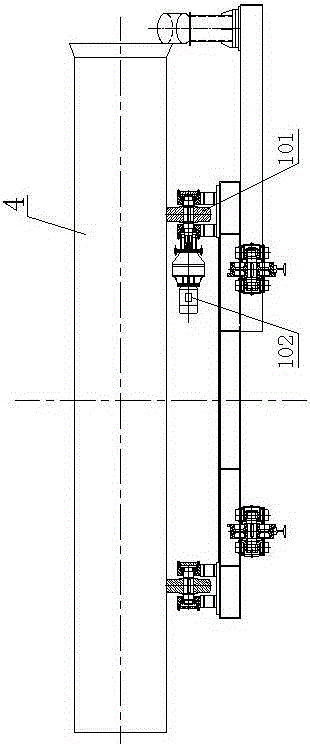

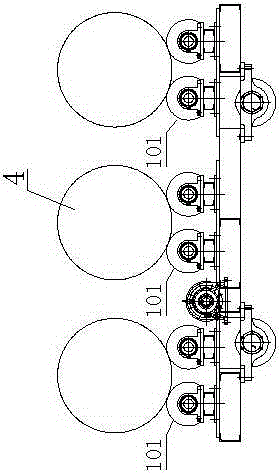

[0040] In the second step, the processed pipe 4 is placed on the supporting wheel 101 of the rotating platform 1 of the coating equipment by means of a transfer t...

Embodiment 2

[0047] The ductile iron pipe lining process, the specific steps are:

[0048] In the first step, the inner wall of the rough pipe of the ductile iron pipe is ground and shot blasted. In this embodiment, the blank pipe material is a resin sand molded centrifugal ductile iron pipe, and its manufacturing process belongs to the prior art.

[0049] In the second step, the processed pipe 4 is placed on the supporting wheel 101 of the rotating platform 1 of the coating equipment by means of a transfer tool, and the frequency conversion motor 102 connected to the supporting wheel 101 is started to drive the pipe to rotate. In this embodiment, the pipe 4 The caliber is DN1600mm, and the speed is 15rpm.

[0050] In the third step, start the heating torch 3 placed under the pipe 4 to preheat the outer wall of the pipe. In this embodiment, the temperature is controlled between 170° C. and 220° C., and the preheating takes 25 minutes.

[0051] The fourth step, after the preheating is com...

Embodiment 3

[0055] The ductile iron pipe lining process, the specific steps are:

[0056] In the first step, the inner wall of the rough pipe of the ductile iron pipe is ground and shot blasted. In this embodiment, the blank pipe material is a water-cooled metal type centrifugal ductile iron pipe.

[0057] In the second step, place the treated pipe 4 on the supporting wheel 101 of the rotating platform 1 of the coating equipment by using a transfer tool, and start the frequency conversion motor 102 connected to the supporting wheel 101 to drive the pipe 4 to rotate. The diameter of the pipe 4 is DN1000mm , the speed is 18rpm.

[0058] The third step is to start the heating torch 3 placed under the pipe 4 to preheat the outer wall of the pipe, the temperature is controlled between 180°C and 230°C, and the preheating time is 20 minutes.

[0059] In the fourth step, after the preheating is completed, use the fabric trolley 2 to evenly distribute the ABS engineering plastic powder on the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com