Spindle device for ensuring installing concentricity of cotton picker head

A cotton picker and concentricity technology, which is applied in the fields of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of unsatisfactory picking effect, cleaning rate and doffing effect, easy loss and neglect of concentricity, etc. Good doffing effect, good picking effect, and the effect of ensuring concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

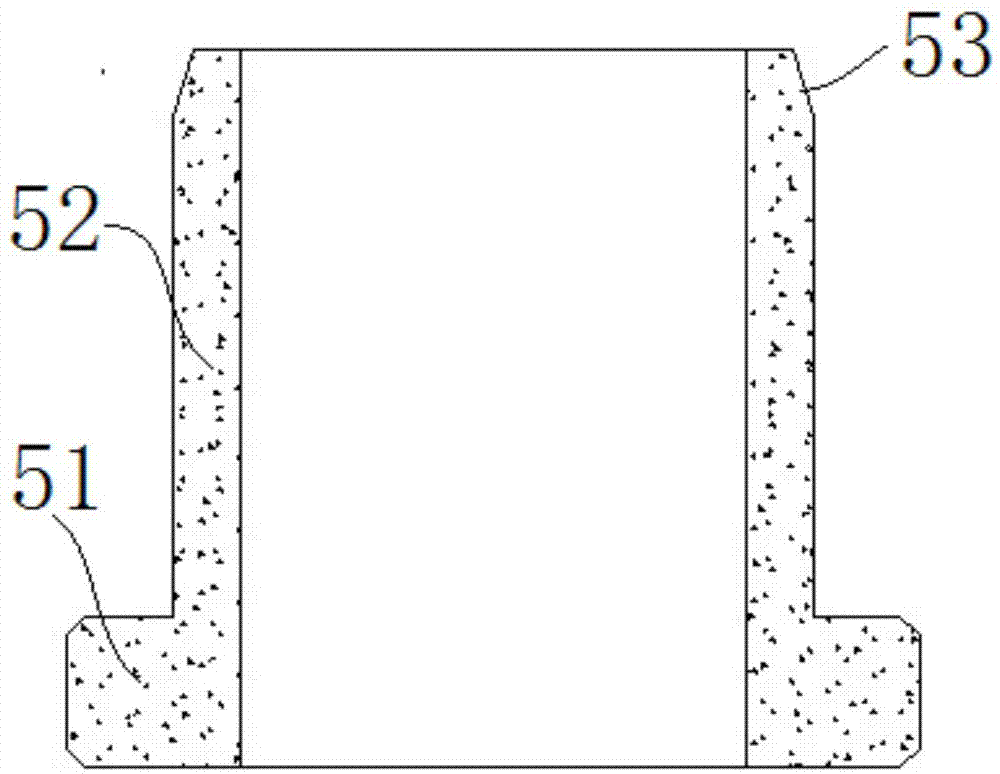

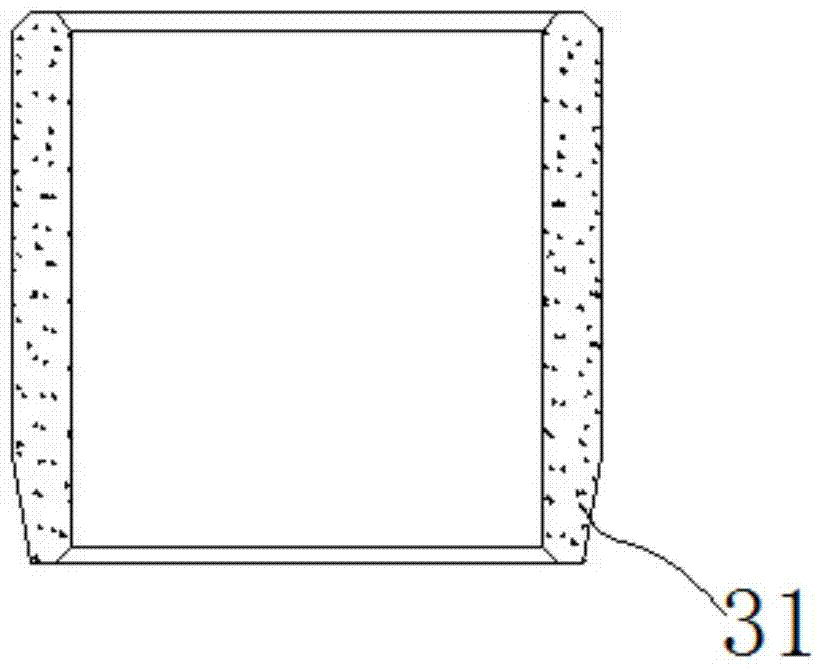

[0024] combine figure 1 , figure 2 , image 3 with Figure 4 , a kind of ingot picking device for the head of a cotton picker that ensures the installation concentricity of the present embodiment includes a spindle picking 1, a bevel gear 7, a spindle picking seat tube 6 and a spindle picking positioning mechanism, and the picking spindle 1 includes a spindle picking rod 12 1. The ingot bevel gear 11 arranged at the rear end of the ingot bar 12 and the ingot head 13 arranged at the front end of the ingot bar 12. The ingot positioning mechanism includes an ingot sleeve 4 fixedly arranged in the inner cavity of the ingot sleeve 4 The first picking spindle bearing 3 and the second picking spindle bearing 5, wherein the first picking spindle bearing 3 is a hollow cylinder, and the lower end surface of the first picking spindle bearing 3 is provided with a first chamfer 31, which ensures picking Concentricity in the assembly process of the device; the first spindle bearing 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com