Method for preparing battery core by automatic winding and automatic winding machine

A technology of battery roll and film winding machine, which is applied in the direction of assembling battery machine, battery manufacturing, alkaline storage battery, etc. The effect of less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

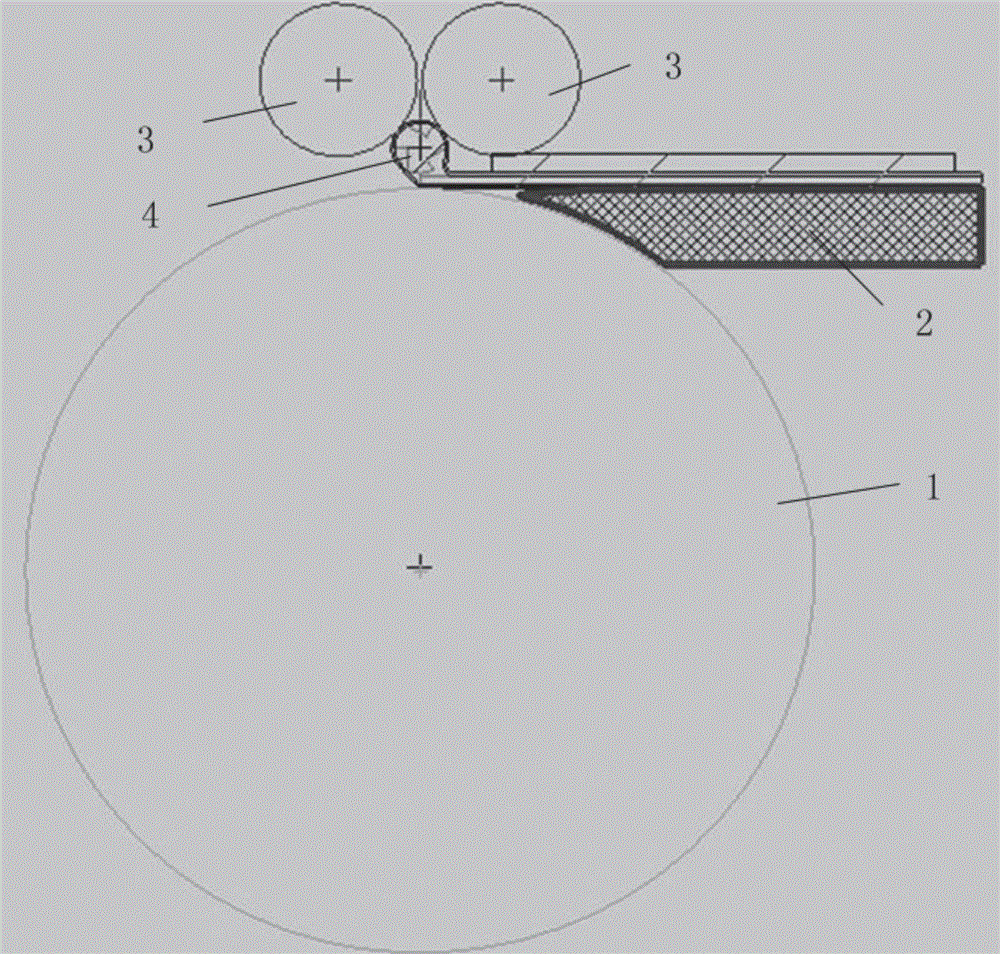

[0027] see figure 1 , the method for preparing a battery core by automatic winding provided by the present invention comprises the following steps:

[0028] (1) An automatic film winding machine is set, which includes a lower pressure wheel 1, an upper pressure wheel group, a film needle 4 arranged between the upper pressure wheel group and the lower pressure wheel 1, and one arranged on the lower pressure wheel 1 The rolling film platform 2 on the top, and a transmission device connected with the above-mentioned components;

[0029] (2) Turn on the power supply, the above-mentioned automatic film rolling machine is in working condition, a diaphragm paper is set on the described film rolling platform 2, a negative pole piece is set on the described diaphragm paper, driven by the transmission device Lift the lower pressure wheel 1; then turn the above-mentioned diaphragm paper over and fold it in half, wrap the winding needle 4, set a positive plate on the diaphragm paper, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com