Piezoelectric electret film and preparation method thereof

A piezoelectric electret, thin film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. Reliable lamination of solid outer layers, etc., to achieve the effect of good performance, simplified operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

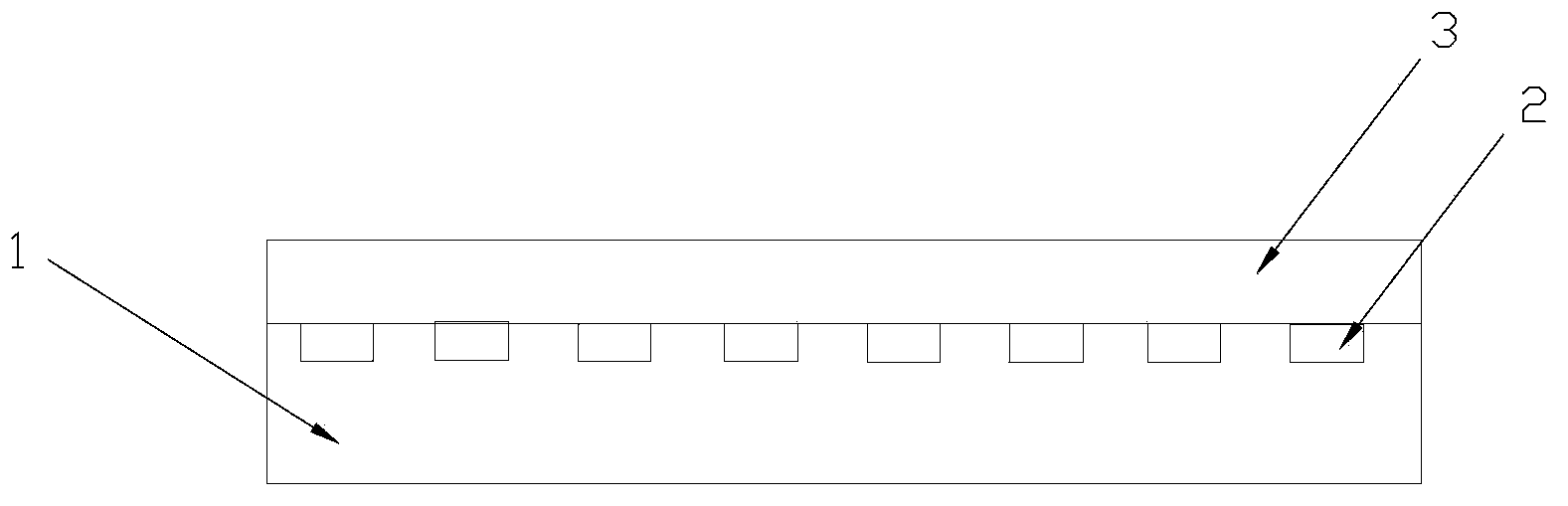

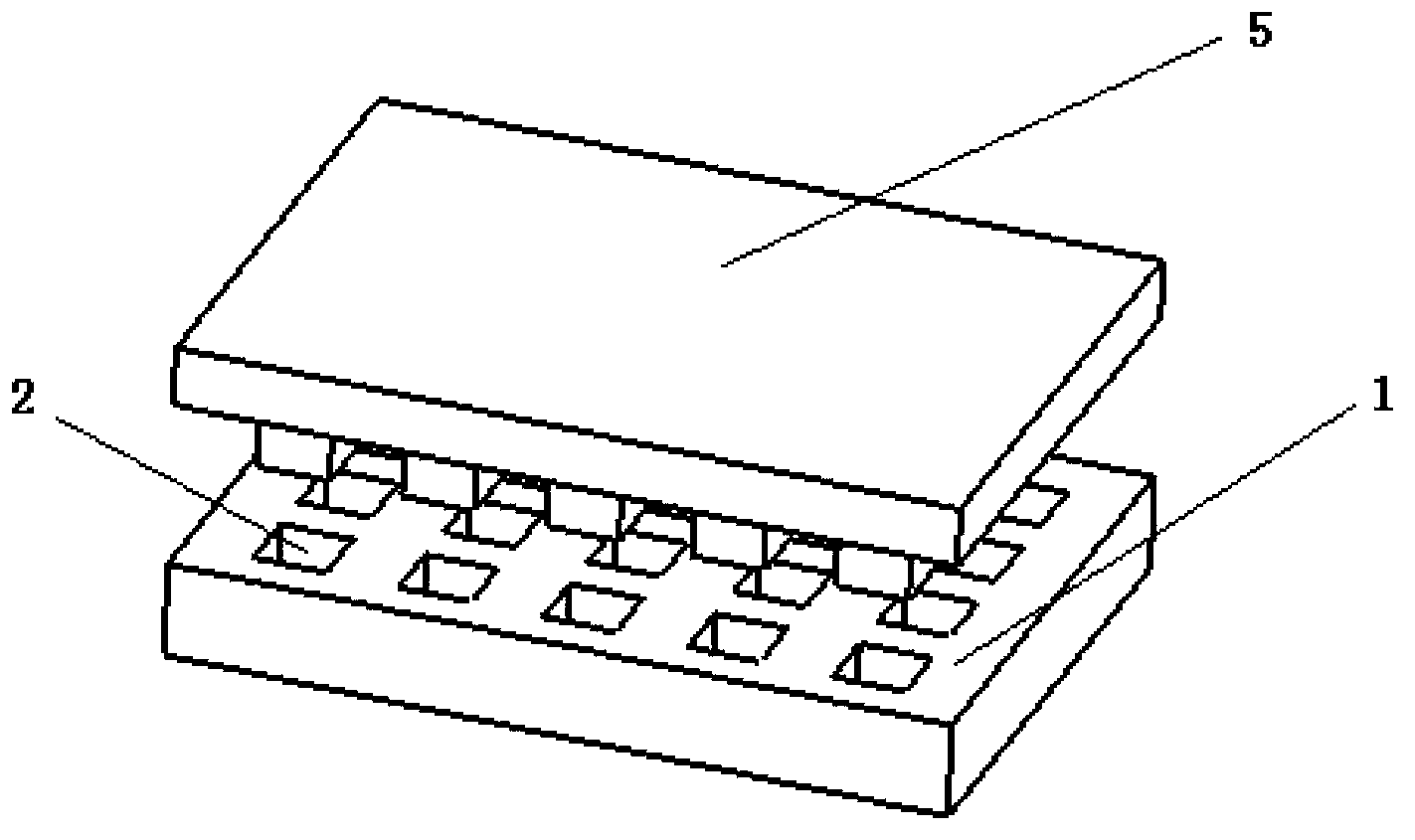

[0039] The invention provides a method for preparing a piezoelectric electret film, comprising steps: (1) coating a polymer solution on a template with protrusions, and then drying; after drying, removing the template to obtain a template with pits (2) combining the dried first polymer film of step (1) with at least one second polymer film to form a cavity; and (3) making step (2) ) The inner surface of the cavity formed is charged, thereby forming a piezoelectric electret film.

[0040] Attached below Figure 1-5 The contents of the present invention will be described.

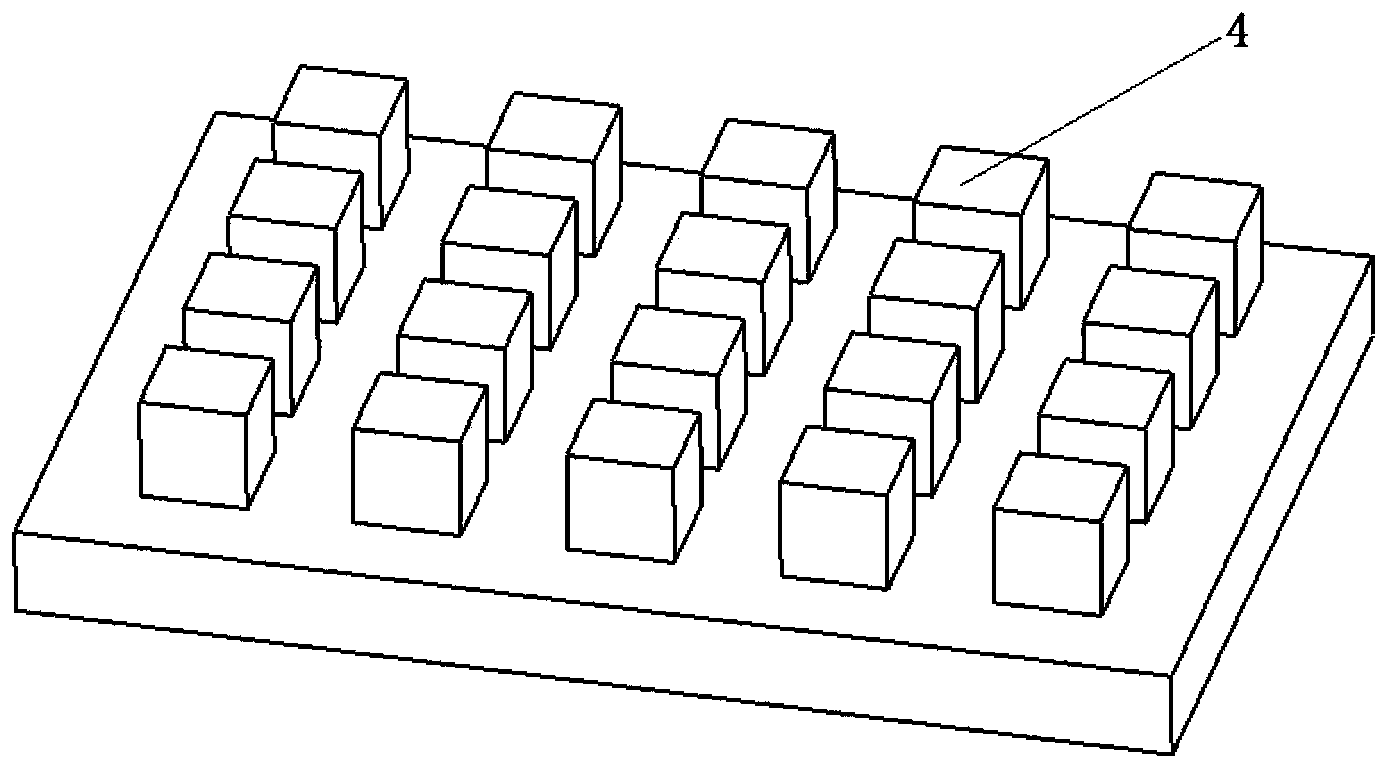

[0041]Wherein, step (1) is a process of forming the polymer film into a polymer film of a suitable shape as required. In this step, the thickness of the coating polymer is greater than the height of the protrusions on the template to ensure that the depth of the pits on the obtained first polymer film layer is consistent with the height of the protrusions on the template, so as to satisfy the piezoelectric ...

Embodiment 1

[0054] Put 1g of PVDF into a 100mL beaker, use a 10mL graduated cylinder to measure 8ml of dimethylacetamide (DMF) into the beaker to dissolve PVDF (11.7wt%), then seal the beaker with plastic wrap, ultrasonic for 30min, PVDF All dissolved, and later used.

[0055] The above prepared PVDF solution is evenly and directly coated on the prepared PDMS soft template with cuboid protrusions by spin coating (the height of the raised cuboid of the template is 10 microns, and the bottom surface is a square with a side length of 6 microns, The interval between the protrusions is 10 microns), and the coating is controlled so that the thickness of the PVDF film after drying is 100 microns. After coating, it is placed in a vacuum dryer at 80° C. for 1 hour. After drying, the PDMS soft template was removed. A PVDF film with a pit array is obtained, and then a layer of PVDF film is coated on the surface of the pit film by spin coating to adjust the depth of the pits so that the depth of the...

Embodiment 2

[0059] Put 2g of PVDF into a 150mL beaker, use a 20mL graduated cylinder to measure 15ml of dimethylacetamide (DMF) into the beaker to dissolve PVDF (11.7wt%), then seal the beaker with plastic wrap, ultrasonic for 30min, PVDF All dissolved, and later used.

[0060] The above prepared PVDF solution is evenly and directly coated on the prepared PDMS soft template with cuboid protrusions by electrostatic spraying (the height of the raised cuboid of the template is 10 microns, and the bottom surface is a square with a side length of 6 microns. The distance between the coatings is 10 microns), and the coating is controlled so that the thickness of the PVDF film after drying is 100 microns. After coating, it is placed in a vacuum desiccator at 80°C for 1 hour. After drying, the PDMS soft template was removed. Obtain a PVDF film with an array of pits, and then coat a layer of PVDF film on the surface of the pit film by electrostatic spraying method to adjust the depth of the pits s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com