Method utilizing two texture indexes to jointly determine tuna flesh freshness

A technology of tuna and indicators, which is applied in the direction of material inspection, food testing, etc., can solve the problems of no fish freshness change indicators, etc., and achieve the effect of fast and accurate judgment and improvement of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

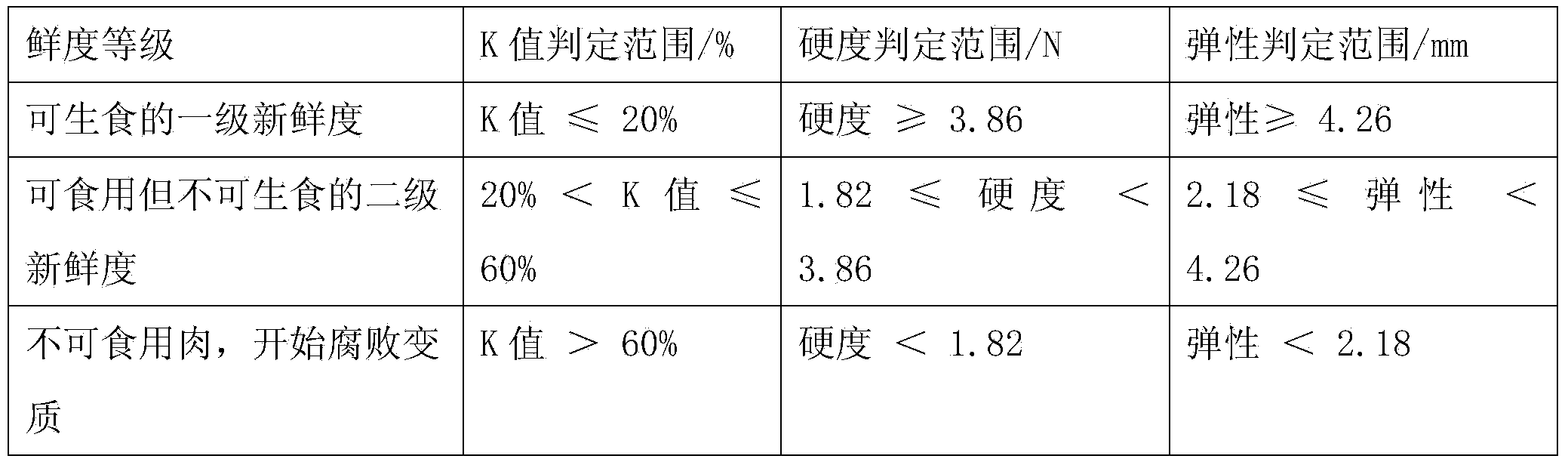

[0049] Embodiment 1. A method for judging the freshness of tuna meat by using two texture indicators, using frozen bigeye tuna naked meat as the test object (that is, the test object is frozen tuna meat), and the following steps are carried out in sequence:

[0050] 1) Thaw the frozen tuna meat to be tested at 4°C, and cut it along the direction of the muscle fibers into pieces with a thickness of 1.5cm and a length=width=3cm after the thawing is complete (the central temperature of the sample reaches 4°C, which means the thawing is complete). Cube-shaped thin slices, to obtain the tuna meat sample to be tested;

[0051] 2) Put the cut fish at a storage temperature of 4°C, then start timing, and take 8 time points (0d; 1d; 2d; 3d; 4d; 5d; 6d; 7d); Physical properties were measured with a texture analyzer TA-XT2i.

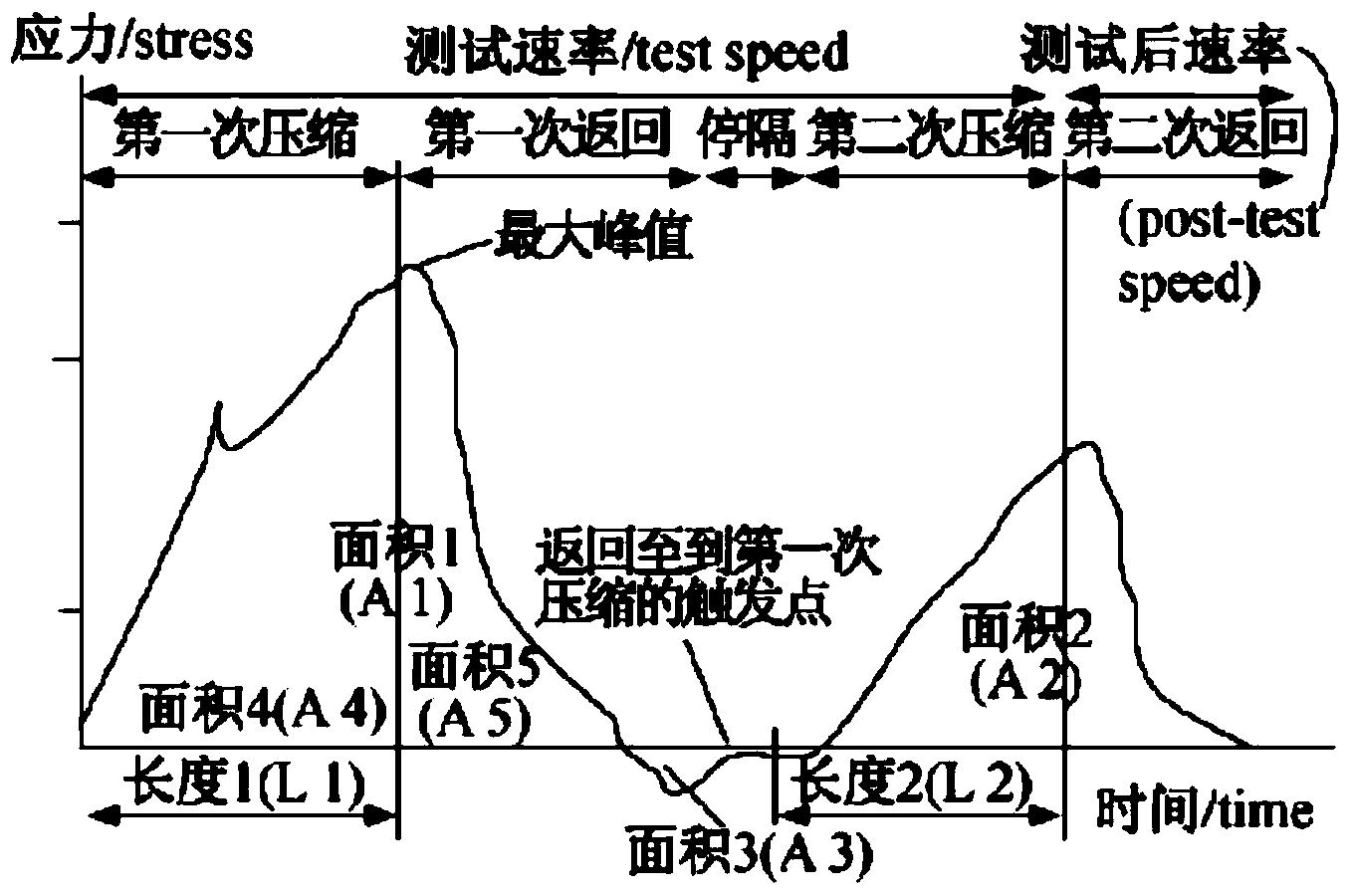

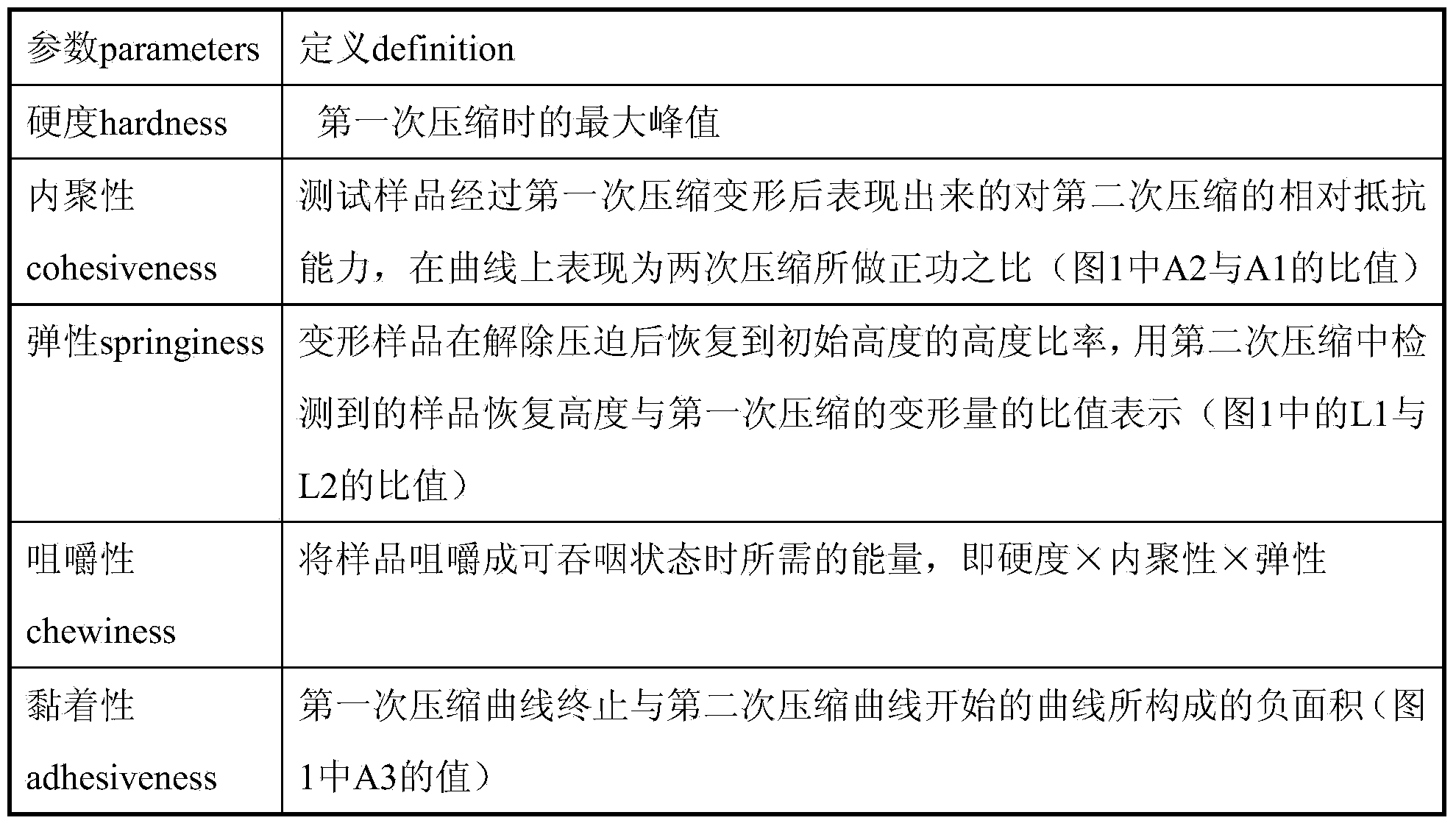

[0052] TPA measurement of physical properties: Place the fish sample flat on the texture analyzer platform, and compress the fish twice through a spherical probe w...

Embodiment 2

[0084] Embodiment 2, the other two batches of frozen bigeye tuna naked meat in the cold storage are tested according to the method described in Example 1 for two texture indicators of hardness and elasticity (only 0d, 2d, 4d, 7d are detected. 4 time points); and according to the scope of judging the freshness of fish by using two texture indicators described in Example 1, the corresponding results were obtained.

[0085] The results obtained are shown in Table 8:

[0086] Table 8. Texture changes and freshness determination of naked meat of bigeye tuna at 4℃

[0087]

[0088] Carry out routine K value detection with the frozen bigeye tuna meat of 2 batches described in above-mentioned embodiment 2, the conclusion obtained is as follows:

[0089] The results obtained are shown in Table 9:

[0090] Table 9. Changes in K value of bigeye tuna naked meat at 4°C

[0091]

[0092]

[0093] Using the judgment basis of hardness and texture to judge the freshness of the nake...

Embodiment 3

[0094] Example 3. Take frozen bigeye tuna naked as the object to be tested. The thawing and cutting methods are the same as step 1 in Example 1). Put the cut fish meat at a storage temperature of 15°C to start timing, and take 7 time points (0h, 12h , 24h, 36h, 48h, 60h, 72h); during storage, the fish meat texture and K value were operated according to the method described in Example 1, and the corresponding results were obtained:

[0095] 1) Changes in texture and K value of fish flesh at 15°C storage temperature are shown in Table 10:

[0096] Table 10. Changes in meat texture and K value of naked tuna bigeye at 15°C

[0097] Detection time / h

[0098] Note: In the texture index of fish meat, the detection value of the stickiness factor changes little with the detection time, so it can be ignored.

[0099] 2) Correlation analysis of each TPA value and K value in the fish meat texture index at 15°C storage temperature: through the correlation analysis program in SPS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com