Hot and humid gas energy recovery high-temperature heat production system

A technology of energy recovery and thermal system, which is applied in the direction of steam generation using heat carrier, climate sustainability, energy-saving heating/cooling, etc. The effect of thermal quality, convenient application and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

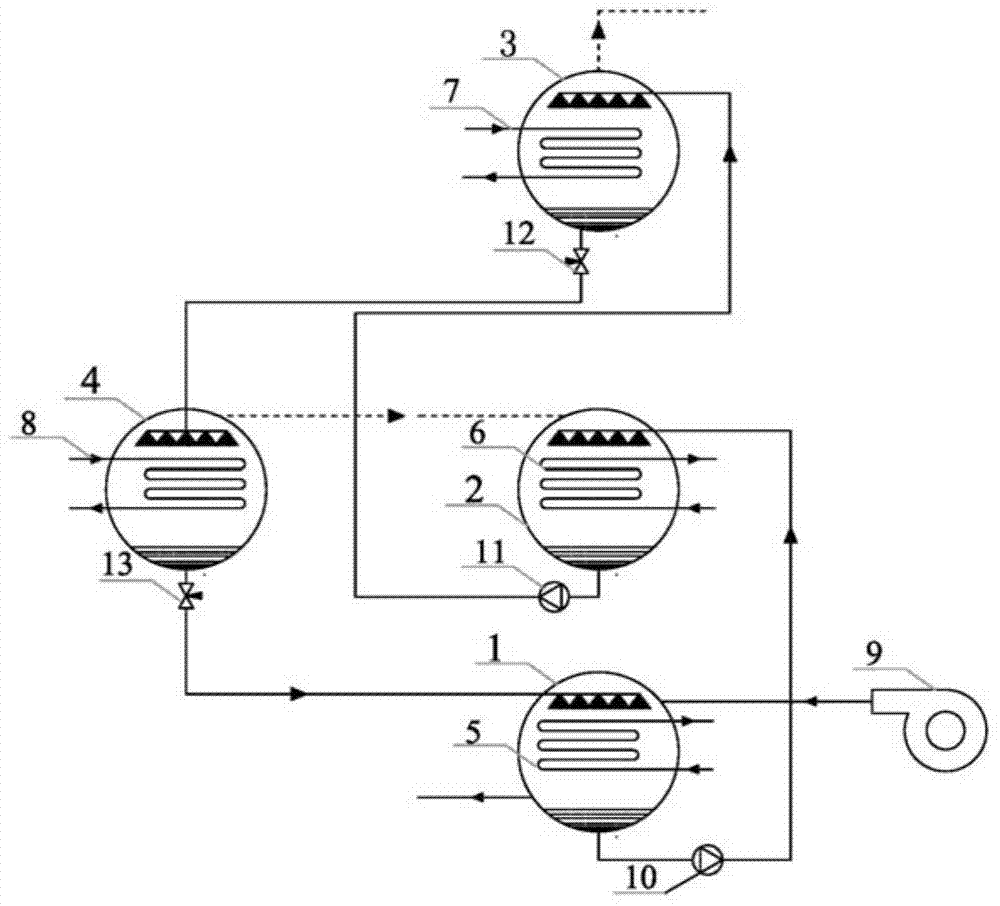

[0046] Such as figure 1 As shown, the hot and humid gas energy recovery high-temperature heat generation system in Example 1 includes a primary absorber 1, a secondary absorber 2, a primary generator 3, a secondary generator 4, a first absorption heat exchange tube 5, a second Two absorption heat exchange pipes 6 , a first heat supply pipe 7 , a second heat supply pipe 8 , a fan 9 , a first solution pump 10 , a second solution pump 11 , a first throttle valve 12 and a second throttle valve 13 .

[0047] The liquid absorbent used in the system is lithium bromide aqueous solution, and the working fluid in the absorption heat exchange tube is water; the external heat source of the heat supply tube is steam; , Circulating flow in the secondary generator 4. The gas passes through the fan 14, the gas inlet of the primary absorber 1, and the gas outlet of the primary absorber 1 to complete the gas circuit. The first heat supply pipe 7 and the second heat supply pipe 8 provide heat ...

Embodiment 2

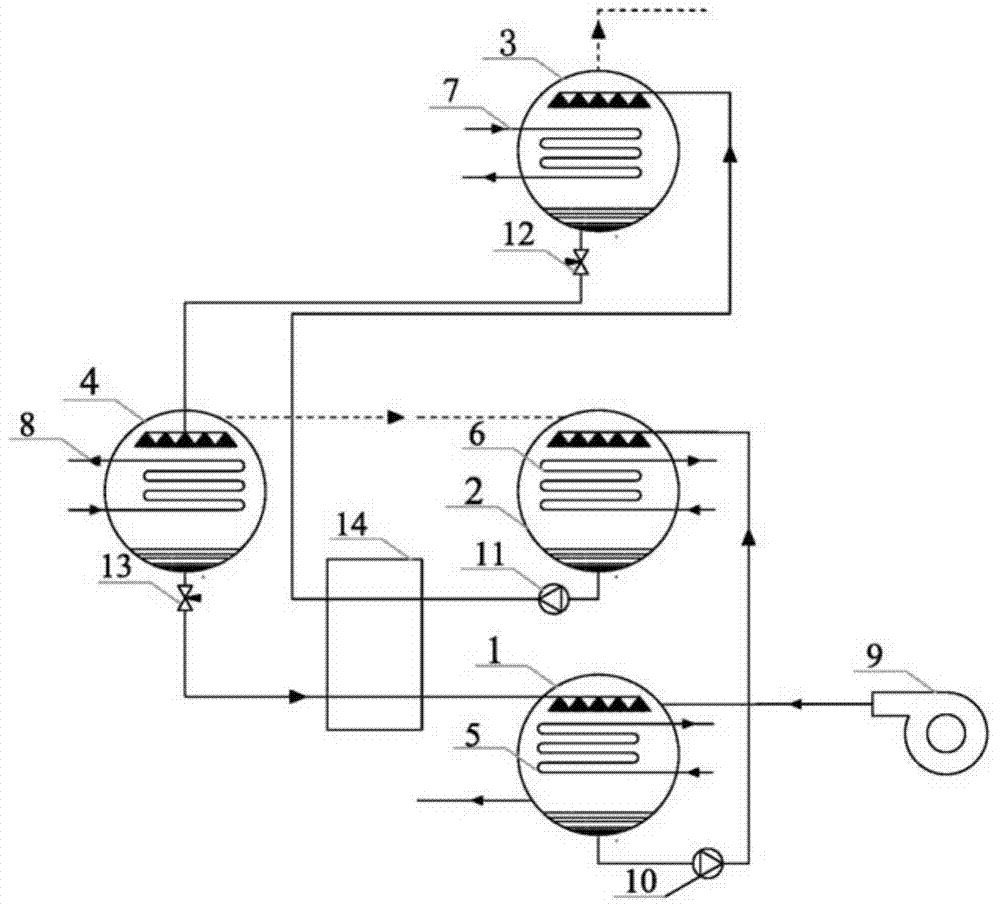

[0049] Such as figure 2 As shown, the hot and humid gas energy recovery high-temperature heat generation system in Example 2 includes a primary absorber 1, a secondary absorber 2, a primary generator 3, a secondary generator 4, a first absorption heat exchange tube 5, a second Two absorption heat exchange pipes 6, a first heat supply pipe 7, a second heat supply pipe 8, a fan 9, a first solution pump 10, a second solution pump 11, a first throttle valve 12, a second throttle valve 13 and Solution heat exchanger 14. The solution heat exchanger 14 includes a first heat exchange pipeline (low temperature pipeline) and a second heat exchange pipeline (high temperature pipeline).

[0050] The liquid absorbent used in the system is lithium bromide aqueous solution, and the working fluid in the absorption heat exchange tube is water; the external heat source of the heat supply tube is steam; , Circulating flow in the secondary generator 4. The gas passes through the fan 14, the g...

Embodiment 3

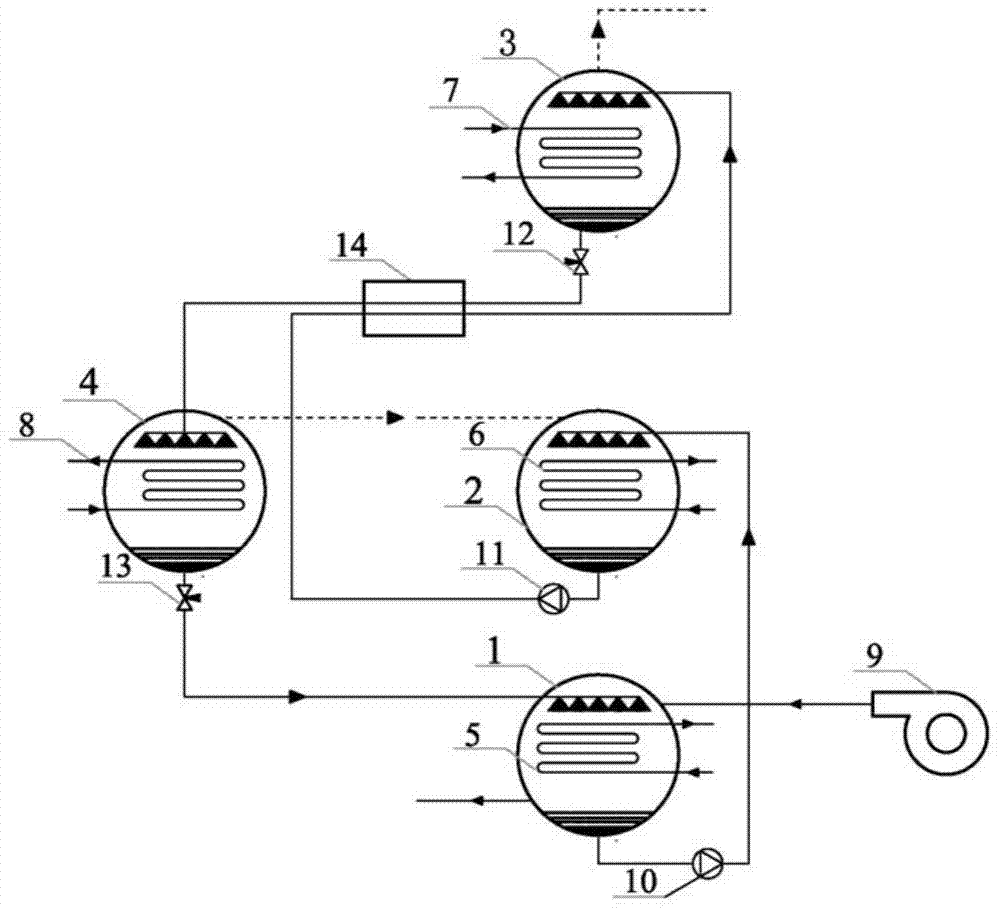

[0052] Such as image 3 As shown, the hot and humid gas energy recovery high-temperature heat production system in Example 3 includes a primary absorber 1, a secondary absorber 2, a primary generator 3, a secondary generator 4, a first absorption heat exchange tube 5, a second Two absorption heat exchange pipes 6, a first heat supply pipe 7, a second heat supply pipe 8, a fan 9, a first solution pump 10, a second solution pump 11, a first throttle valve 12, a second throttle valve 13 and Solution heat exchanger 14. The solution heat exchanger includes a first heat exchange line (also known as a low temperature line) and a second heat exchange line (also known as a high temperature line). The difference between this embodiment and the system of Embodiment 2 is that the arrangement position of the solution heat exchanger 14 is different. In this embodiment, the liquid absorbent outlet of the secondary absorber 2 is connected with the liquid absorbent inlet of the primary genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com