Method for rapidly and stably arranging equipment on fully mechanized coal mining face

A technology of fully mechanized mining face and equipment, applied in mining equipment, ground mining, earthwork drilling and other directions, can solve the problems of time-consuming, consumables, labor and other problems of stable installation methods, save materials, optimize operating procedures, and speed up stability. The effect of loading progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

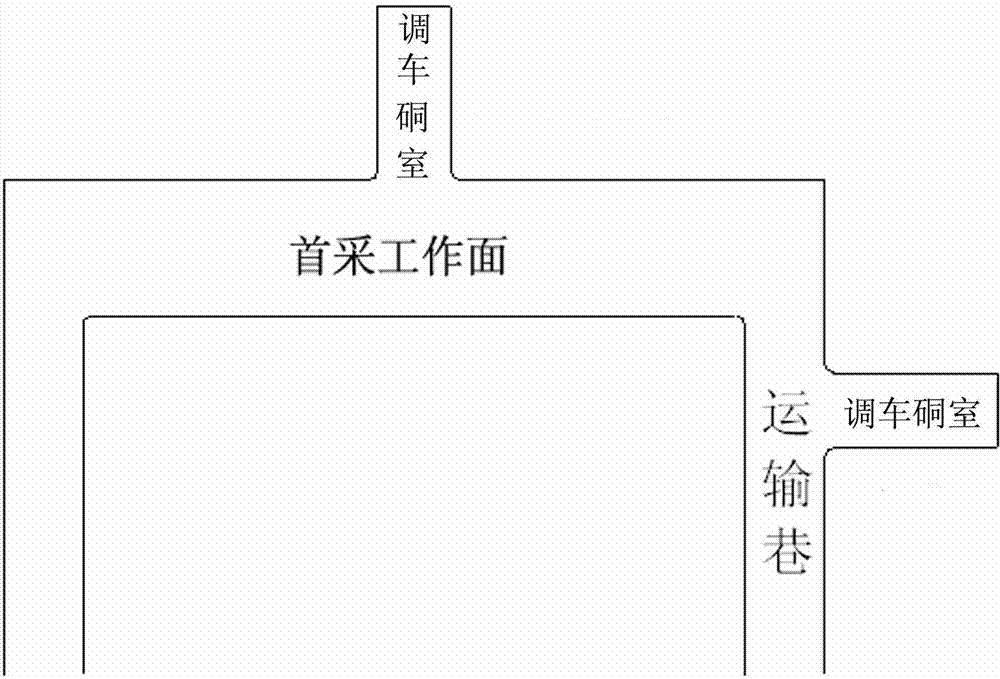

Image

Examples

Embodiment Construction

[0010] The method of fast and stable installation of fully mechanized mining face equipment, first install the equipment train, then transport and install the belt self-moving tail and reloading crusher, while installing the reloading crusher, simultaneously install the belt conveyor along the groove, and then transport and install the front Conveyor nose and rear conveyor nose, transport and install the front conveyor chute from the conveyor nose to the conveyor tail, and lay the front conveyor top and bottom chains, and install coal mining when the front conveyor chute is installed in the machine nest Then install all the remaining front conveyor chutes, then transport from the nose of the conveyor to the tail of the conveyor and install the rear conveyor chute, and simultaneously transport and install the hydraulic support. After the hydraulic support and the rear conveyor chute are installed, Install the front conveyor tail and the rear conveyor tail, and finally lay the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com