Fracture prevention and heat preservation wall structure

A technology of thermal insulation wall and anti-cracking mortar layer, applied in thermal insulation, walls, building components, etc., can solve the problem of poor shear resistance, water and frost resistance, poor aging resistance, affecting the overall quality of the wall, and the Insufficient bonding strength of thermal insulation boards to achieve the effect of improving crack resistance and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

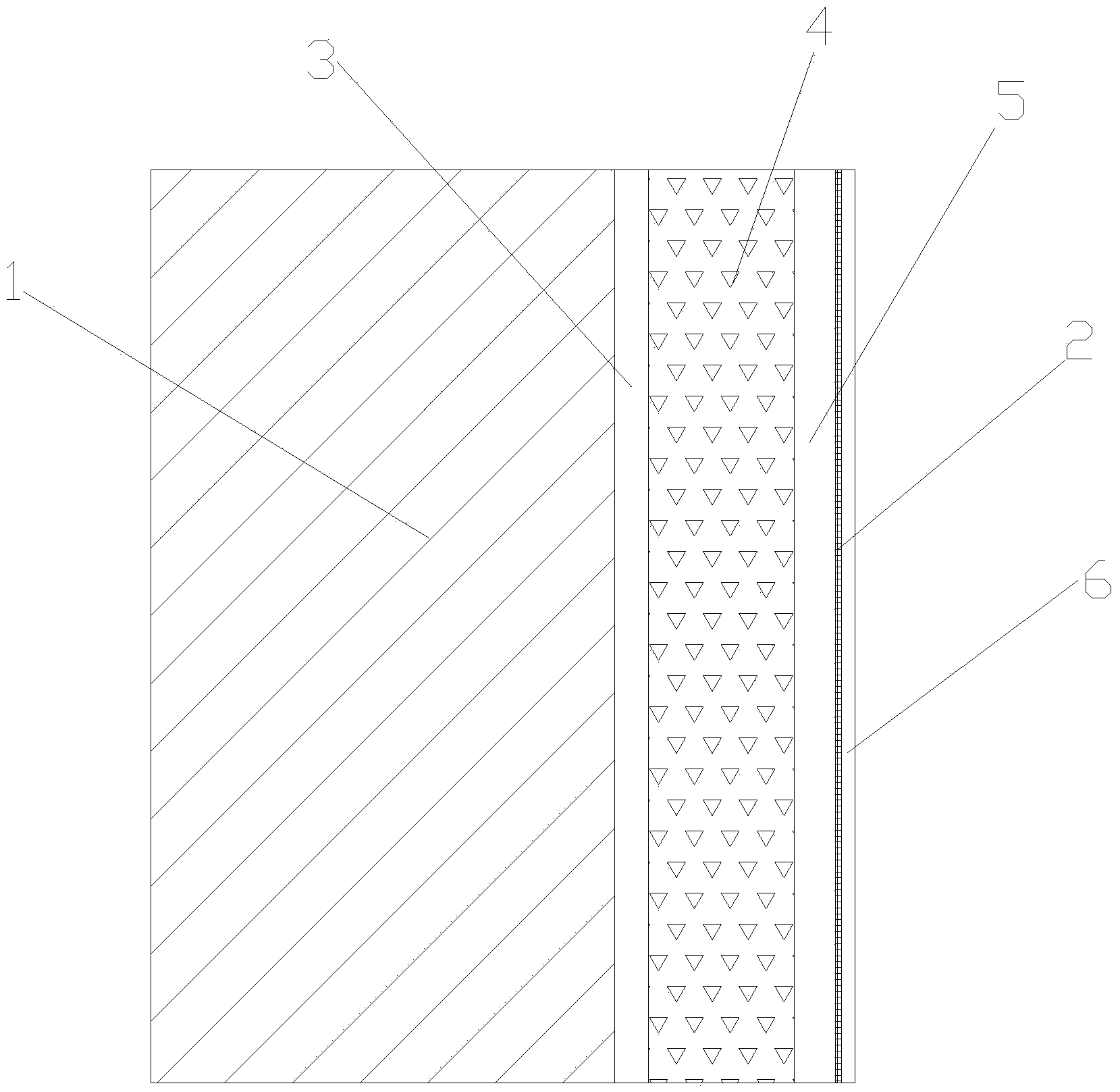

[0015] attached figure 1 It is a kind of anti-cracking and thermal insulation wall structure according to the present invention, which includes foundation wall 1 and grid cloth 2, the lap width between the planes of the mesh cloth 2 is ≥50 mm, and the lap joint at the inner corner ≥100 mm, and the overlap at the external corner is ≥200 mm; an interface mortar layer 3, an insulation mortar layer 4 and an anti-cracking mortar layer 5 are arranged between one side of the grid cloth 2 and the foundation wall 1 in sequence, and the interface mortar layer The thickness of the layer 3 is 1-2 mm, the thickness of the thermal insulation mortar layer 4 is <20 mm, and the thickness of the anti-cracking mortar layer 5 is 6-8 mm; Exterior paint layer 6.

[0016] According to the solution of the present invention, an interface mortar layer 3, a thermal insulation mortar layer 4 and an anti-cracking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com