A Construction Method for Steel-Concrete Composite Frames Connected by Cross Bolts

It is a technology of piercing bolts and construction methods, which is applied in the processing of building materials, construction, and building construction. It can solve the problems of affecting concrete pouring inside and outside the pipe, a large amount of welding workload, and difficult construction, so as to achieve efficient construction organization. The effect of reducing welding processing workload and reducing residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

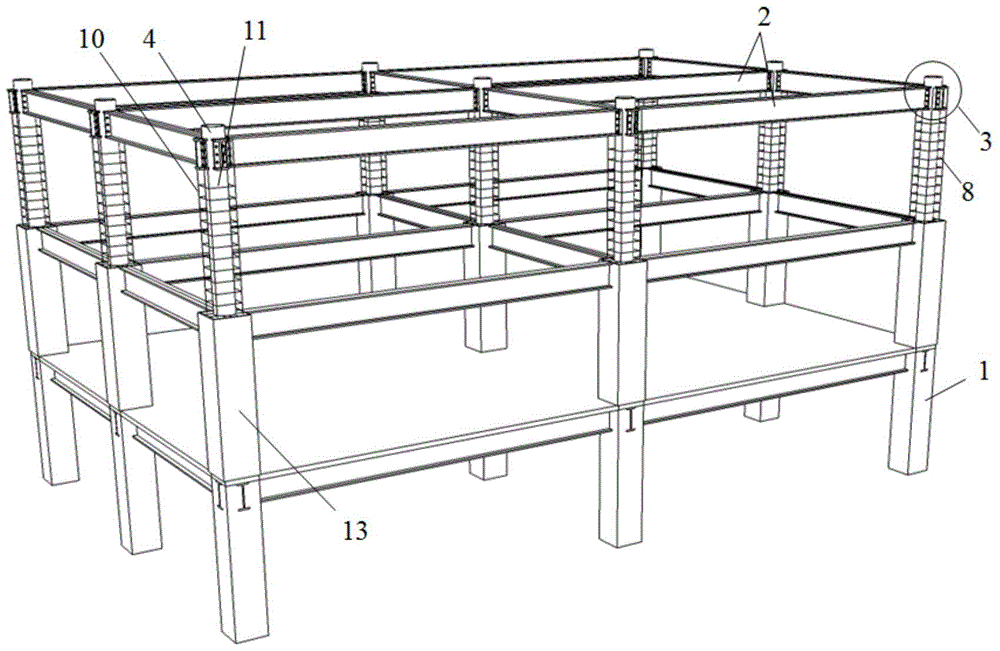

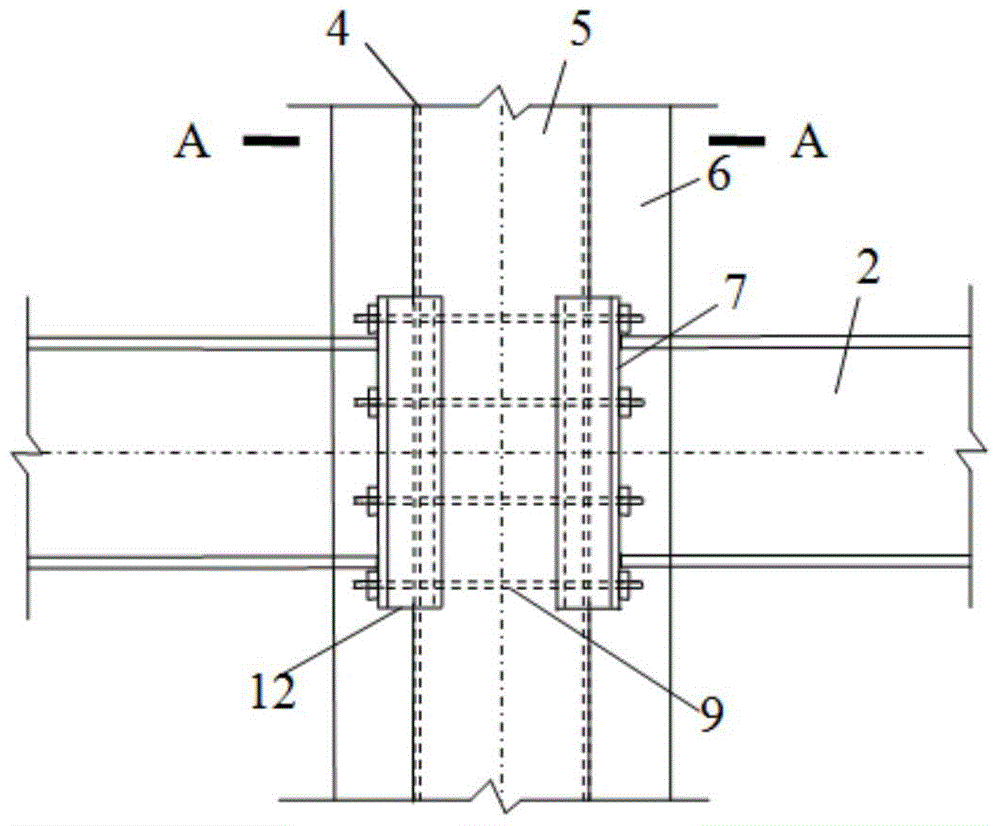

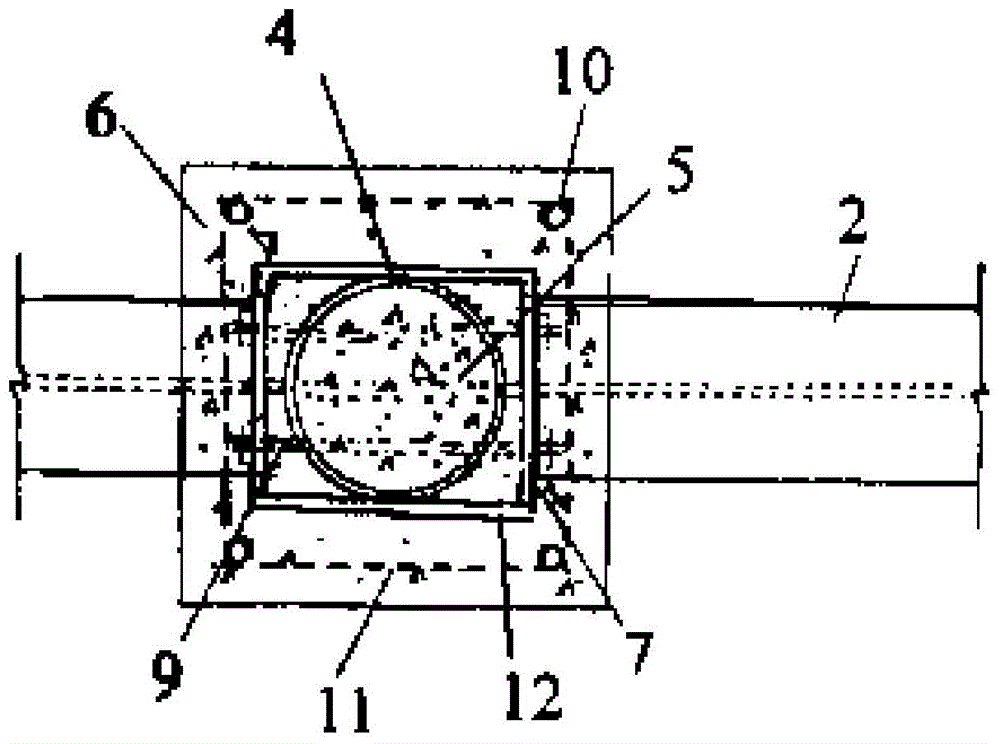

[0030] For the steel-concrete composite frame connected by bolts and the specific implementation method of construction, according to Figure 1-3 In the construction of the steel-concrete composite frame structure connected by bolts as shown, during the construction, for each floor, the circular inner steel pipe column 4 and the steel beam 2 inside the steel pipe concrete composite column 1 are hoisted to the designated position, Use the piercing bolts to pass through the holes on the end plate 7 and the inner steel pipe column 4, and tighten the piercing bolts with nuts at both ends to make them closely connected with the steel pipe components. After the connection is completed, pour the inner core concrete 5 in the inner steel pipe column 4, Then the peripheral longitudinal bars 10 and stirrups 11 are bound to form a peripheral reinforcement cage 8, and the external support formwork 13 is supported outside the peripheral reinforcement cage 8, and concrete is poured in the ext...

Embodiment 2

[0032] The construction method is exactly the same as that of Example 1, except that the interior of the steel tube concrete composite column is a square inner steel tube column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com