Plasma assisted magnetron sputtering depositing method

A plasma and sputtering deposition technology, applied in the direction of sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of unstable working conditions, difficulty in obtaining high-purity compound films, and decreased deposition rate, etc. problem, to achieve the effect of stable coating process, improved coating efficiency, and large lens volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

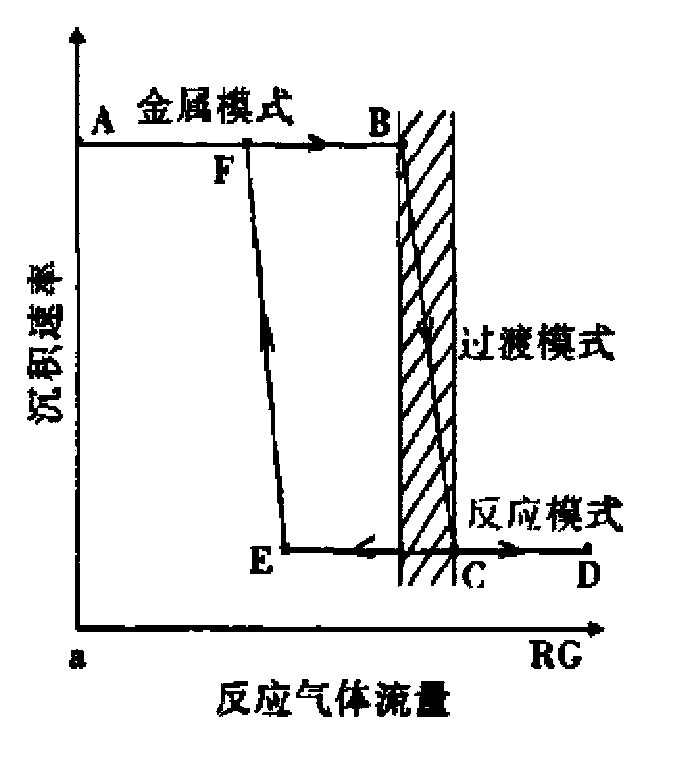

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Alumina (Al 2 o 3 ) thin films are widely used in the fields of optics, optoelectronics, information display and storage devices due to their physical and chemical properties such as high transmittance, high chemical stability, high insulation, high temperature resistance, and high hardness. At the same time, it is also one of the preferred materials for ceramic dielectric thin films in medium and high temperature solar photothermal selective absorption coatings.

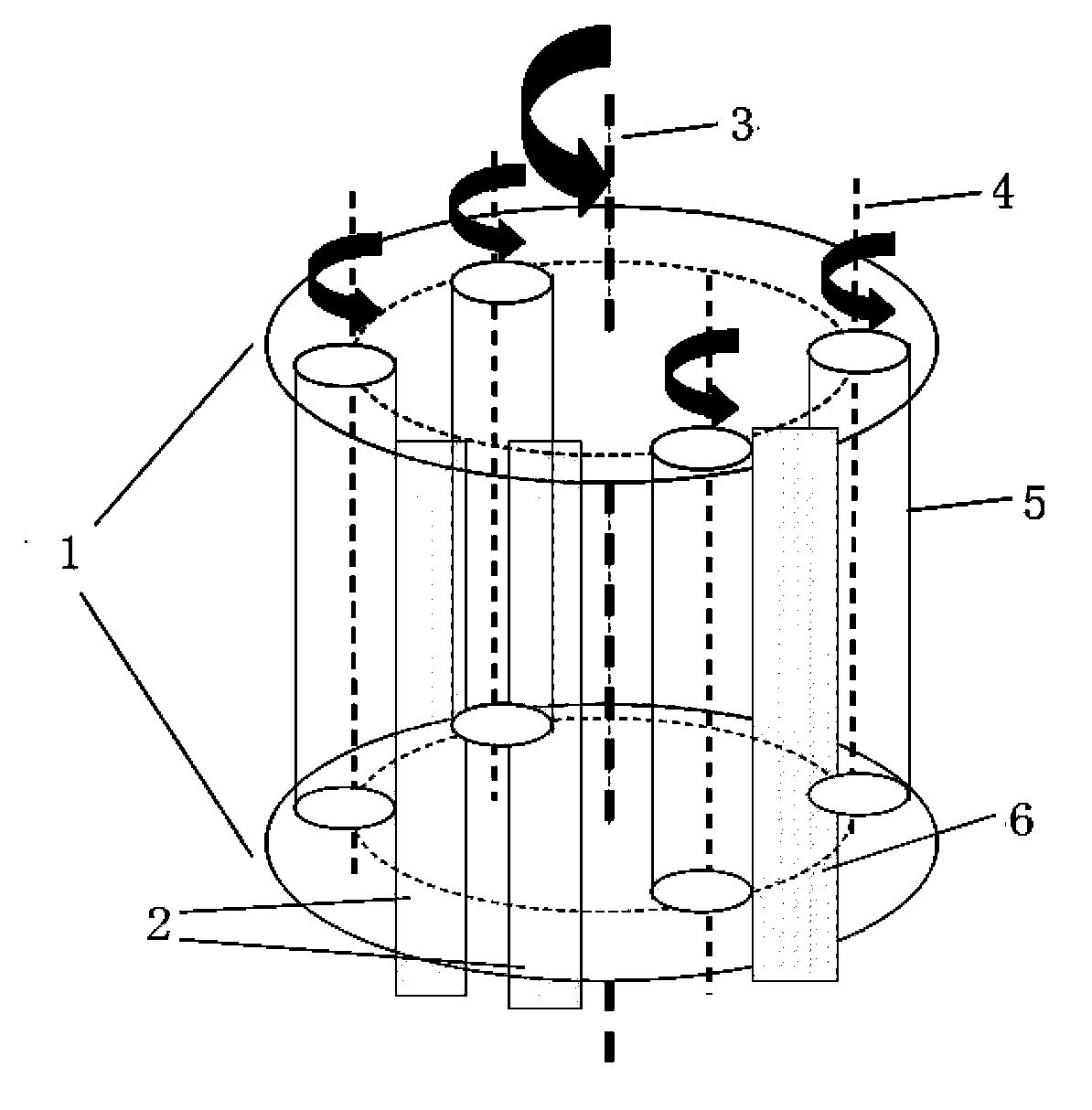

[0061] Using the ACS700 advanced magnetron sputtering coating equipment produced by Dalian Far East Vacuum Technology Co., Ltd., the trial production of aluminum oxide film was carried out by using the present invention. The unbalanced closed magnetic field medium frequency twin target reactive magnetron sputtering method is adopted, and two twin metal aluminum targets with a purity of 99.99 are used. The target area is 563mm×106mm; the distance between the target and the substrate is about 120mm. The vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com