A kind of multiphase steel and preparation method thereof

A complex-phase steel and microstructure technology, applied in the field of hot-rolled steel plate production, can solve the problems of deteriorated wheel welding performance, high Al content, and increased manufacturing cost, and achieve the effects of easy phase transformation strengthening, high strength, and increased strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

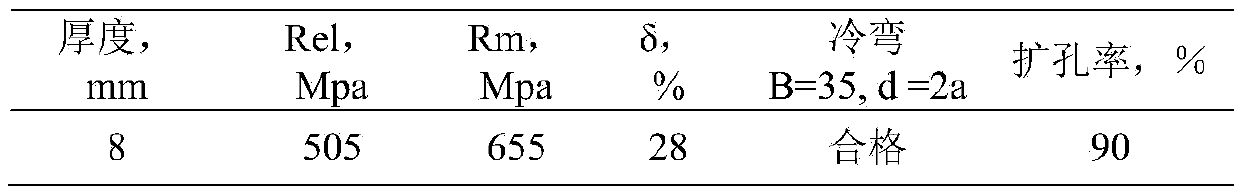

[0057] Embodiment 1: Select the chemical composition of high-strength steel, the percentage by weight is: C: 0.06%, Si: 0.62%, Mn: 1.5%, Ti: 0.036%; Cr: 0.62%; P: 0.049%; S: 0.003% ; Al: 0.032%; O: 0.0003%; N: 0.0005%; the rest is iron Fe and unavoidable impurities. The above-mentioned prepared raw materials were smelted on a 120-ton converter, and continuously cast into a continuous casting slab of 175mm×1250mm×11800mm, the continuous casting slab was heated to 1240°C for 170 minutes, and rolled on a hot continuous rolling mill. The rolling start temperature is controlled at 1150°C, the rough rolling finish rolling temperature is controlled at 1050°C, the rough rolling is carried out for 5 passes, the finish rolling start temperature is controlled at 1010°C, the finish rolling finish rolling temperature is controlled at 860°C, and the finish rolling is carried out for 5 passes , Water cooling is used between the finishing mills; the above-mentioned billets after rolling are s...

Embodiment 2

[0060] Embodiment 2: Select the chemical composition of high-strength steel, the weight percentage is: C: 0.08%, Si: 0.8%, Mn: 0.9%, Ti: 0.02%; Cr: 1.03%; P: 0.049%; S: 0.002% ; Al: 0.022%; O: 0.00035%; N: 0.00045%; the rest is iron Fe and unavoidable impurities.

[0061] The above-mentioned prepared raw materials were smelted on a 120-ton converter, and continuously cast into a continuous casting slab of 175mm×1230mm×11800mm, the continuous casting slab was heated to 1255°C for 160 minutes, and the rough rolling start temperature was controlled at 1200°C , The rough rolling finish rolling temperature is controlled at 1030°C, the rough rolling is 5 passes, the thickness of the intermediate billet is 35mm, after that, the intermediate billet is finished rolling, the finish rolling start temperature is controlled at 990°C, the finish rolling finish rolling temperature is controlled at 862°C, 6 passes of finishing rolling, water cooling is adopted between the finishing mills; the...

Embodiment 3

[0065] Embodiment 3: Select the chemical composition of high-strength steel, the weight percentage is: C: 0.92%, Si: 1.0%, Mn: 1.75%, Ti: 0.02%; Cr: 0.53%; P: 0.029%; S: 0.002% ; Al: 0.045%; O: 0.00029%; N: 0.00042%; the rest are iron Fe and unavoidable impurities.

[0066] The above-mentioned prepared raw materials were smelted on a 120-ton converter and continuously cast into a continuous casting slab of 175mm×1230mm×11800mm. The continuous casting slab was heated to 1265°C for 150 minutes, and the rough rolling start temperature was controlled at 1180°C , The rough rolling finish temperature is controlled at 1040°C, the rough rolling is 5 passes, the thickness of the intermediate billet is 34mm, after that, the intermediate billet is finished rolling, the finish rolling start temperature is controlled at 1000°C, and the finish rolling finish temperature is controlled at 872°C, 6 passes of finishing rolling, water cooling is adopted between the finishing mills; the above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com