Method for recycling scandium from red mud slag

A technology of red mud and slag, which is applied in the field of metallurgy, can solve problems such as troublesome processing technology, low comprehensive utilization, and waste slag discharge, and achieve the effects of high reaction completion, good product quality, and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

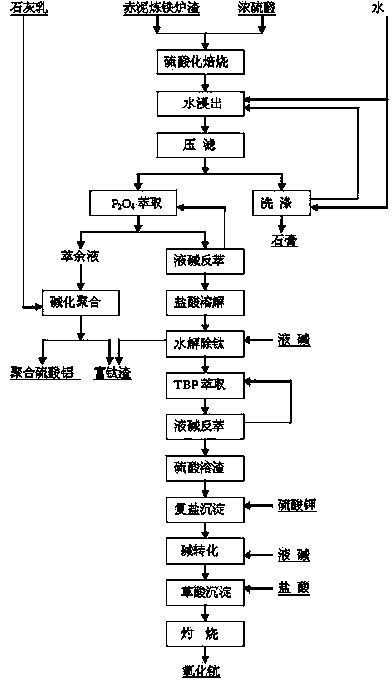

Image

Examples

Embodiment 1

[0054] The solid waste red mud produced by alumina contains 8% iron in the slag after iron recovery. The slag is mixed with concentrated sulfuric acid for sulfation roasting. Water, soak in water for 1.5 hours, filter, and extract the metal salt mixed solution after water soaking and filtering with P2O4 extraction mixed solvent, the volume ratio of P2O4 extraction mixed solvent and metal salt mixed solution is 1:8, separate the organic phase, and use 100g / L of sodium hydroxide solution back-extracts the organic phase to obtain a scandium-rich precipitate with a content of 1.31%. The back-extracted precipitate is dissolved with 2mol / L hydrochloric acid, and then heated and hydrolyzed after adding 80 g / L of sodium hydroxide solution to adjust the pH value of the solution to 1.5; The filtrate after filtering to remove titanium is extracted with tributyl phosphate, the organic phase is back-extracted with 90g / L sodium hydroxide solution, the back-extracted residue is dissolved wit...

Embodiment 2

[0056] The solid waste red mud produced by alumina contains 5% iron in the slag after iron recovery, and the slag is mixed with concentrated sulfuric acid for sulfation roasting. The weight of the slag and concentrated sulfuric acid is 1:1, roasted for 1 hour, and then added twice Water, soak in water for 2 hours, filter, and extract the metal salt mixed solution after water soaking and filtering with P2O4 extraction mixed solvent, the volume ratio of P2O4 extraction mixed solvent and metal salt mixed solution is 1:10, separate the organic phase, and use 100g / 1 L of sodium hydroxide solution back-extracts the organic phase to obtain a scandium-rich precipitate with a content of 1.47%. The back-extracted precipitate is dissolved with 4mol / L hydrochloric acid, and then heated and hydrolyzed after adding 70 g / L potassium hydroxide solution to adjust the pH value of the solution to 2.5; The filtrate after filtering to remove titanium is extracted with tributyl phosphate, the organ...

Embodiment 3

[0058] The red mud is first dried to remove most of the water, so that the water content of the red mud is 12% of the total weight, and the red mud with a certain water content is made into balls, and then the red mud balls are dried by using the heat of the tail gas combustion of the reduction furnace , and then dry red mud balls, coke, limestone, and dolomite are mixed in a ratio of 25:15:2:1, added to the reduction furnace for ironmaking, and iron and slag are obtained by separating iron slag. The slag is added to the reduction furnace for ironmaking. The temperature of the hot air in the reduction furnace for ironmaking is 900-1000°C, the wind pressure is 220mmHg, the melting temperature in the furnace is 1550-1600°C, and the furnace temperature is higher than 1400°C. Iron and slag are obtained by separating the iron slag. The solid waste red mud produced by alumina contains 3% iron in the slag after recycling iron, and the slag is mixed with concentrated sulfuric acid for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com