Method for comprehensive recovery of valuable metals from electroplating sludge and innocent treatment of electroplating sludge

A harmless treatment and electroplating sludge technology, which is applied in the direction of electric furnace, drum furnace, crucible furnace, etc., can solve the problems of chromium toxicity that cannot be eliminated, changes in phase composition, and influence on metal leaching, etc., and achieve less environmental pollution. Simple operation and high metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

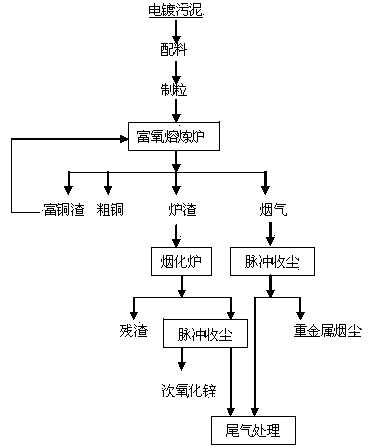

Method used

Image

Examples

Embodiment 1

[0050] 1. Ingredients: Mix the 1# comprehensive electroplating sludge according to the following ratio to mix the materials evenly, and at the same time ensure that the coke powder is excessive. The ratio of ingredients:

[0051] 1# comprehensive electroplating sludge: 800kg

[0053] Quartz stone: 120kg

[0054] Limestone: 50kg

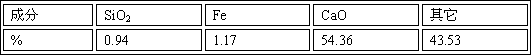

[0055] Table 1 Components of 1# comprehensive electroplating sludge (%)

[0056]

[0057] 2. Granulation: Send the prepared materials to the granulator for granulation, the particle size is 20-30mm in diameter;

[0058] 3. Smelting: Add the raw material particles made of electroplating sludge into the oxygen-enriched smelting furnace. After the feeding is completed, the burner gun is inserted into the furnace for smelting. At the beginning of melting, the oxygen-enriched smelting furnace first rotates around the central axis of the furnace at a slow speed, and the speed is 1r / min and then increases continuously, and ...

Embodiment 2

[0066] 1. Ingredients: Mix the 2# comprehensive electroplating sludge according to the following proportions to mix the materials evenly, and at the same time ensure that the coke powder is excessive. The proportion of ingredients:

[0067] 2# comprehensive electroplating sludge: 600kg

[0068] Coke powder: 150kg

[0069] Quartz stone: 100kg

[0070] Limestone: 40kg

[0071] Table 3 Composition of 2# comprehensive electroplating sludge (%)

[0072] ingredients Cu Pb sn Ni Fe Zn Cr Mg Ca S other content 22.54 - 0.25 - 36.99 0.08 3.61 0.19 0.37 2.52 33.45

[0073] 2. Granulation: Send the prepared materials to the granulator for granulation, the particle size is 20-30mm in diameter;

[0074] 3. Smelting: Add the raw material particles made of electroplating sludge into the oxygen-enriched smelting furnace. After the feeding is completed, the burner gun is inserted into the furnace for smelting. At the beginning of melting, t...

Embodiment 3

[0082] 1. Ingredients: 3# comprehensive electroplating sludge, mix the materials evenly according to the following proportions, and at the same time ensure that the coke powder is excessive, the proportion of ingredients:

[0083] 3# comprehensive electroplating sludge: 500kg

[0084] Coke powder: 130kg

[0085] Quartz stone: 80kg

[0086] Limestone: 30kg

[0087] Table 5 Composition of 3# comprehensive electroplating sludge (%)

[0088] ingredients Cu Pb sn Ni Fe Zn Cr Mg Ca S other content 51.24 0.09- 0.02 0.01 14.90 0.07 5.85 0.14 0.22 0.41 27.05

[0089] 2. Granulation: Send the prepared materials to the granulator for granulation, the particle size is 20-30mm in diameter;

[0090] 3. Smelting: Add the raw material particles made of electroplating sludge into the oxygen-enriched smelting furnace. After the feeding is completed, the burner gun is inserted into the furnace for smelting. At the beginning of melting, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com