Special drip tape material

A technology of materials and belts, which is applied in the field of polymer material processing, can solve problems such as poor scratch resistance and weather resistance, bursting of polyethylene drip irrigation belts, and affecting the use and promotion of polyethylene drip irrigation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

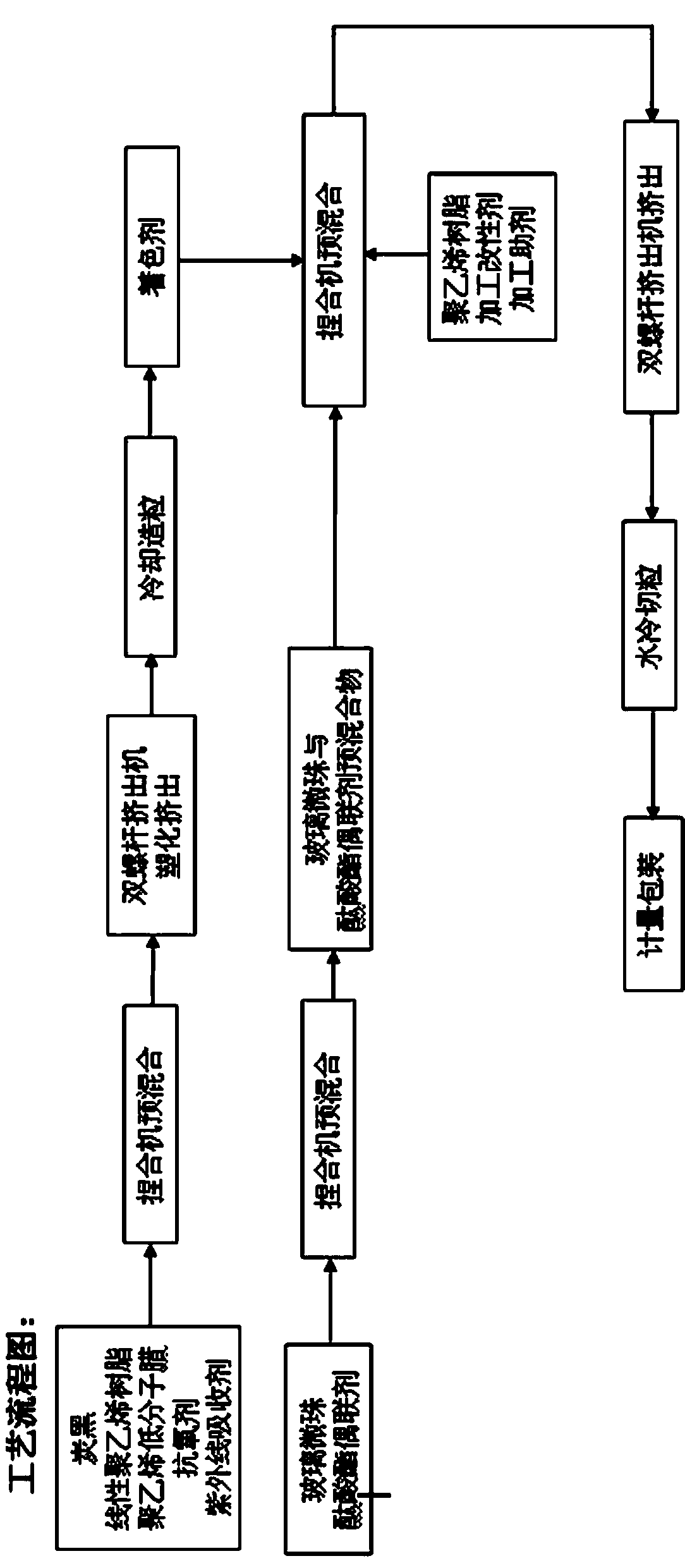

Image

Examples

preparation example Construction

[0016] (1) Preparation of colorant (carbon black masterbatch):

[0017] The coloring agent (carbon black masterbatch) is made of raw materials with the following weight ratio: linear polyethylene resin 60kg, carbon black 40kg, polyethylene low molecular wax 2kg, antioxidant 1.2kg, ultraviolet absorber 0.3kg , linear polyethylene resin, carbon black, polyethylene low-molecular wax, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and tris[2.4-di-tert-butyl Phenyl] phosphite, ultraviolet absorber (2-(2'-hydroxy-3',5'-di-pentylphenyl) benzotriazole) was stirred in a high-speed mixer for 15 minutes at a high speed, and the speed of the mixer was set to Set at 1000-1200 r / min, the fully mixed mixture is plasticized and extruded through a twin-screw extruder, cooled and granulated to prepare a colorant carbon black masterbatch for use.

[0018] Among them, the temperature setting of each section of the twin-screw extruder is: zone 1: 160°C, zone 2: ...

Embodiment 1

[0023] Weigh 100kg of low-density polyethylene resin according to weight ratio; 5kg of carbon black masterbatch (colorant) prepared in (1); 5kg of glass microspheres (toughener); PPA masterbatch (processing modifier) 0.5kg; calcium stearate (processing aid) 0.1kg; first weigh 5kg of glass beads and 0.05kg of titanate coupling agent (in order to make glass beads on polyethylene The resin has better compatibility. Add a proper amount of titanate coupling agent in this formula, the dosage is 1% of the glass microspheres) and mix in a high-speed mixer for 15 minutes (the speed of the mixer is set at 400- 600 r / min), then add the low-density polyethylene resin, colorant, processing modifier and processing aid into the high-speed mixer and mix for 30 minutes (where the mixer speed is set at 800-1200 r / min), fully The mixed mixture is plasticized and extruded by a twin-screw extruder, cooled and granulated to obtain special materials for drip irrigation belts.

[0024] Among them,...

Embodiment 2

[0026] Weigh 80 kg of low-density polyethylene resin according to weight ratio; 20 kg of linear low-density polyethylene resin; 5 kg of carbon black masterbatch (colorant) prepared in (1); glass microspheres (toughener) 5 ㎏; 0.5 kg of PPA masterbatch (processing modifier) prepared in (2); 0.1 kg of calcium stearate (processing aid). The preparation method of the present invention is as follows: first weigh 5 kg of glass microspheres and 0.05 kg of titanate coupling agent (in order to make the glass microspheres have better compatibility with polyethylene resin, an appropriate amount of titanate is added to this formula Coupling agent, the amount of which is 1% of the amount of glass beads) was mixed in a high-speed mixer for 15 minutes (the mixer speed was set at 400-600 r / min), and then the low-density polyethylene was mixed in a high-speed mixer for 30 minutes. Minutes (the speed of the mixer is set at 400-600 r / min) and then the low-density polyethylene resin, colorant, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com