Cement-based composite material and preparation method thereof

A composite material and cement-based technology, applied in cement production and other directions, can solve the problems of failing to meet the high strength and fluidity requirements of ultra-high-performance cement-based composite materials, increasing the safety hazards of building structures, and increasing costs. The effect of increasing strength and reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

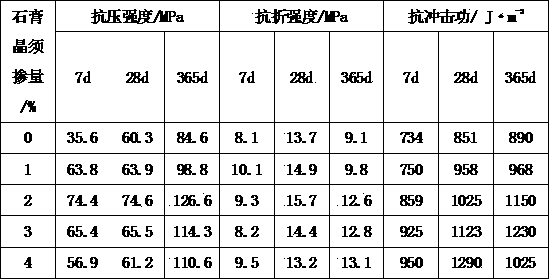

Embodiment 1

[0017] The components of this embodiment: including main materials and auxiliary materials, the main materials are all ordinary Portland cement, and the auxiliary materials include gypsum whiskers and urea. The mass fraction of urea in gypsum whiskers is 0.08%; the table in this embodiment shows that when the mass fraction of gypsum whiskers in the main material is 1%, 2%, 3%, 4%, the cement-based composite Various performance parameters of the material. In addition, various performance parameters of the cement-based composite material without gypsum whiskers are given.

[0018] The preparation method of this embodiment is as follows: adding desulfurized gypsum to a reactor containing water, and controlling the mass fraction ratio of desulfurized gypsum to water to be 0.025:1, 0.05:1, 0.75:1, and 0.1:1; Hydrothermal method, the control temperature is 150℃, the pressure is 0.2MPa, the reaction time is 2h, and the speed of the stirrer in the reactor is 200r / min; during the prepara...

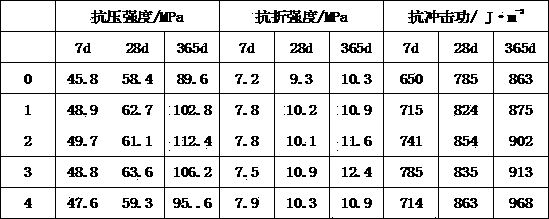

Embodiment 2

[0023] The components of this embodiment: include main materials and auxiliary materials, the main materials include 90% ordinary Portland cement and 10% fly ash, and the auxiliary materials include gypsum whiskers and sodium oleate. The mass fraction of sodium oleate in gypsum whiskers is 0.6%; the table in this example shows that when the mass fraction of gypsum whiskers in the main material is 1%, 2%, 3%, and 4%, the cement The performance parameters of composite materials. In addition, various performance parameters of the cement-based composite material without gypsum whiskers are given.

[0024] The preparation method of this embodiment is as follows: adding desulfurized gypsum to a reactor containing water, and controlling the mass fraction ratio of desulfurized gypsum to water to be 0.025:1, 0.05:1, 0.75:1, and 0.1:1; Hydrothermal method, the control temperature is 165℃, the pressure is 0.23MPa, the reaction time is 2.5h, the speed of the stirrer in the reactor is 250r / m...

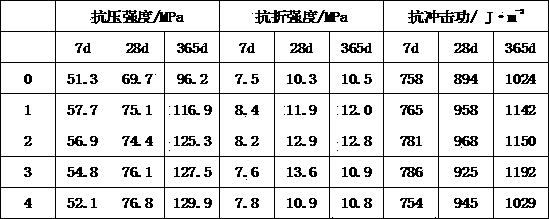

Embodiment 3

[0029] The components of this embodiment include main materials and auxiliary materials. The main materials include 85% ordinary Portland cement and 15% slag, and the auxiliary materials include gypsum whiskers and sodium stearate. The mass fraction of sodium stearate in gypsum whiskers is 0.6%; the table in this example shows that when the mass fraction of gypsum whiskers in the main material is 1%, 2%, 3%, 4%, the Various performance parameters of cement-based composite materials. In addition, various performance parameters of the cement-based composite material without gypsum whiskers are given.

[0030] The preparation method of this embodiment is as follows: adding desulfurized gypsum to a reactor containing water, and controlling the mass fraction ratio of desulfurized gypsum to water to be 0.025:1, 0.05:1, 0.75:1, and 0.1:1; Hydrothermal method, the control temperature is 174℃, the pressure is 0.28MPa, the reaction time is 3.0h, the speed of the stirrer in the reactor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com