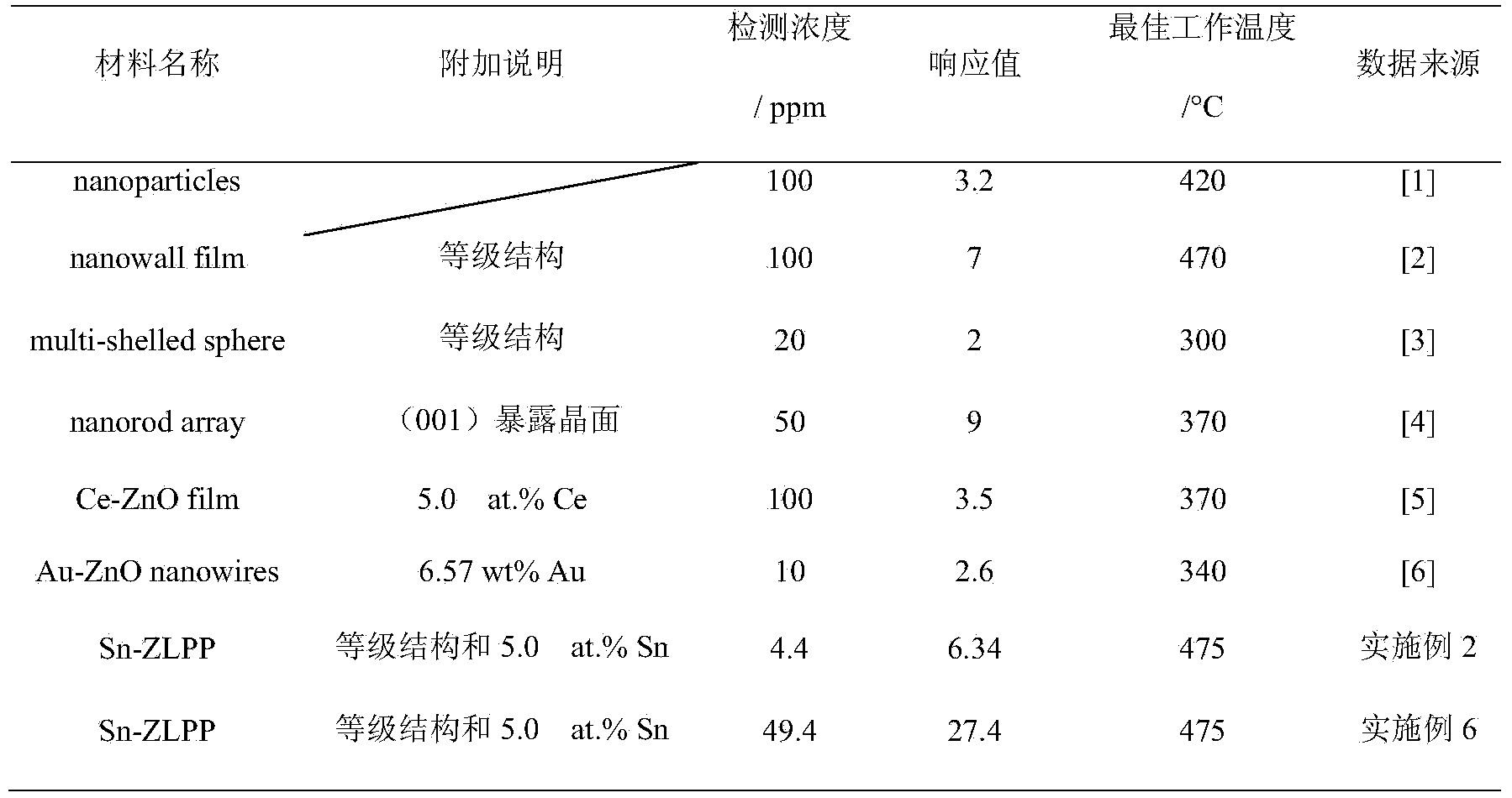

Tin-doped layered porous nanometer zinc oxide as well as preparation method and application thereof

A nano-zinc oxide and tin-doped technology, which is applied in the field of gas-sensitive sensors, can solve problems such as not being able to meet the detection requirements of benzene series, achieve excellent gas-sensing performance, simple method, and improve the effect of surface reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Preparation of tin-doped layered porous nano-zinc oxide: Weigh zinc salts (zinc acetate, zinc sulfate) and dissolve them in water, add stannous chloride at a ratio of 0.1-22.0 at.% and stir to form a white emulsion, slowly add Polyol (such as ethylene glycol, glycerol, 1,2-propanediol, 1,4-butanediol) until a translucent light white mixture is formed, the volume ratio of water to polyol is 1:1-1:6 . Transfer the mixed liquid into a reaction kettle, seal the reaction kettle and heat the hydrothermal reaction. The reaction temperature is 120-200° C., and the reaction time is 12-84 hours. After the reaction, the liquid and solid of the reaction product are separated, and the solid product is washed and dried.

[0020] Characterization of tin-doped layered porous nano-zinc oxide: The morphology of the sample was observed by transmission electron microscope (TEM, JEOL JEM-2100).

[0021] Tin-doped layered porous nano-zinc oxide gas-sensing performance test: The substrate of...

Embodiment 1

[0023] Weigh zinc acetate and add water to dissolve, add stannous chloride according to the ratio of 0.1at.% and stir to form a white emulsion, slowly add ethylene glycol until a translucent light white mixed solution is formed, the volume ratio of water and ethylene glycol is 1:1. Transfer the mixed solution into a reaction kettle, seal the reaction kettle and heat it for hydrothermal reaction. The reaction temperature is 120° C., and the reaction time is 12 hours. After the reaction is completed, the liquid and solid of the reaction product are separated, and the solid product is washed and dried.

Embodiment 2

[0025] Weigh zinc acetate and add water to dissolve, add stannous chloride according to the ratio of 5.0at.% and stir to form a white emulsion, slowly add glycerol until a translucent light white mixed solution is formed, the volume ratio of water and glycerol is 1:6. Transfer the mixed solution into a reaction kettle, seal the reaction kettle and heat the hydrothermal reaction, the reaction temperature is 200° C., and the reaction time is 12 hours. After the reaction is completed, the liquid and solid of the reaction product are separated, and the solid product is washed and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com