Dense-phase conveying system and method

A dense-phase conveying and conveying system technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as pressure fluctuations, unstable and discontinuous powder conveying, achieve stable conveying, and solve series feeding unstable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

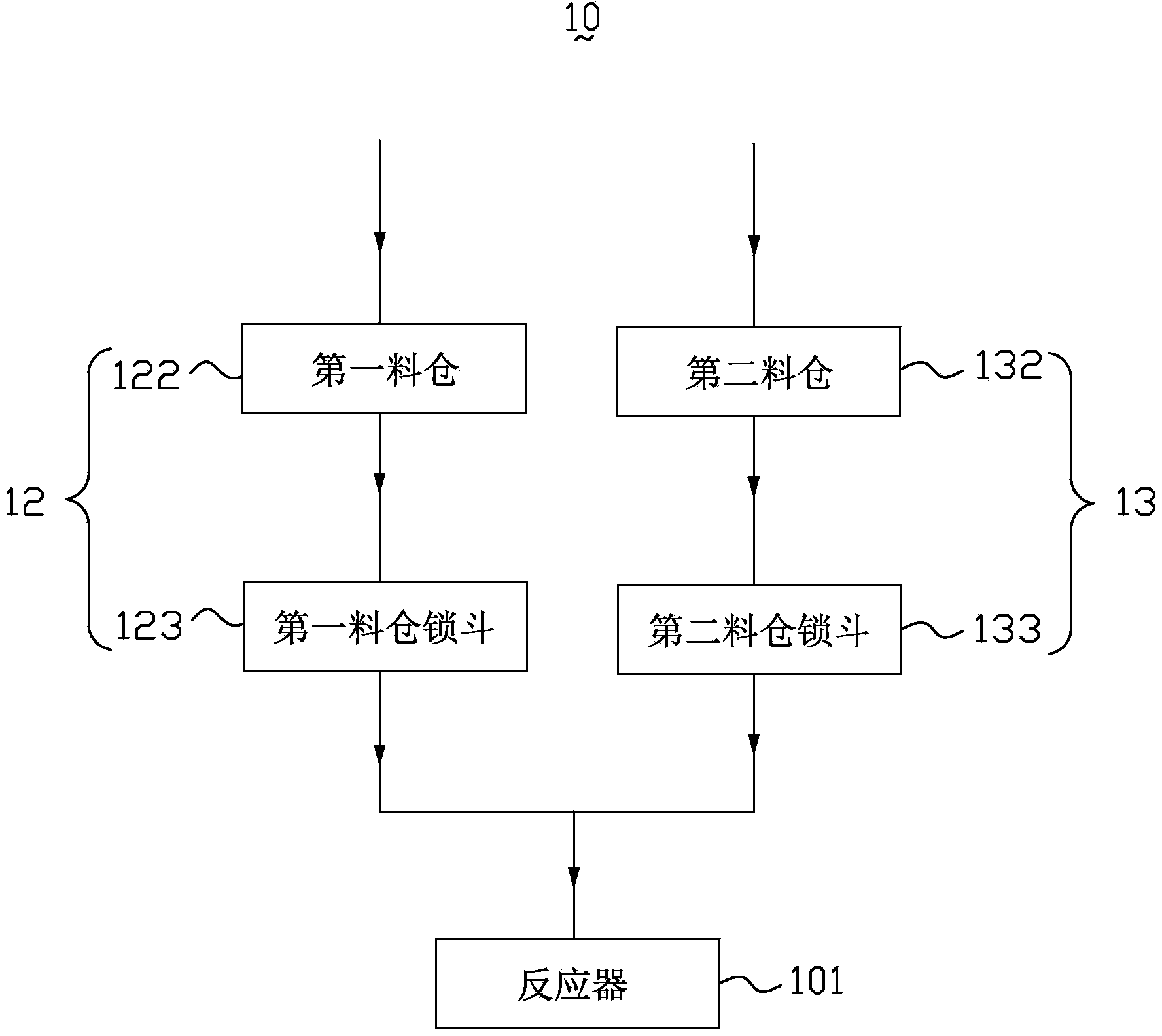

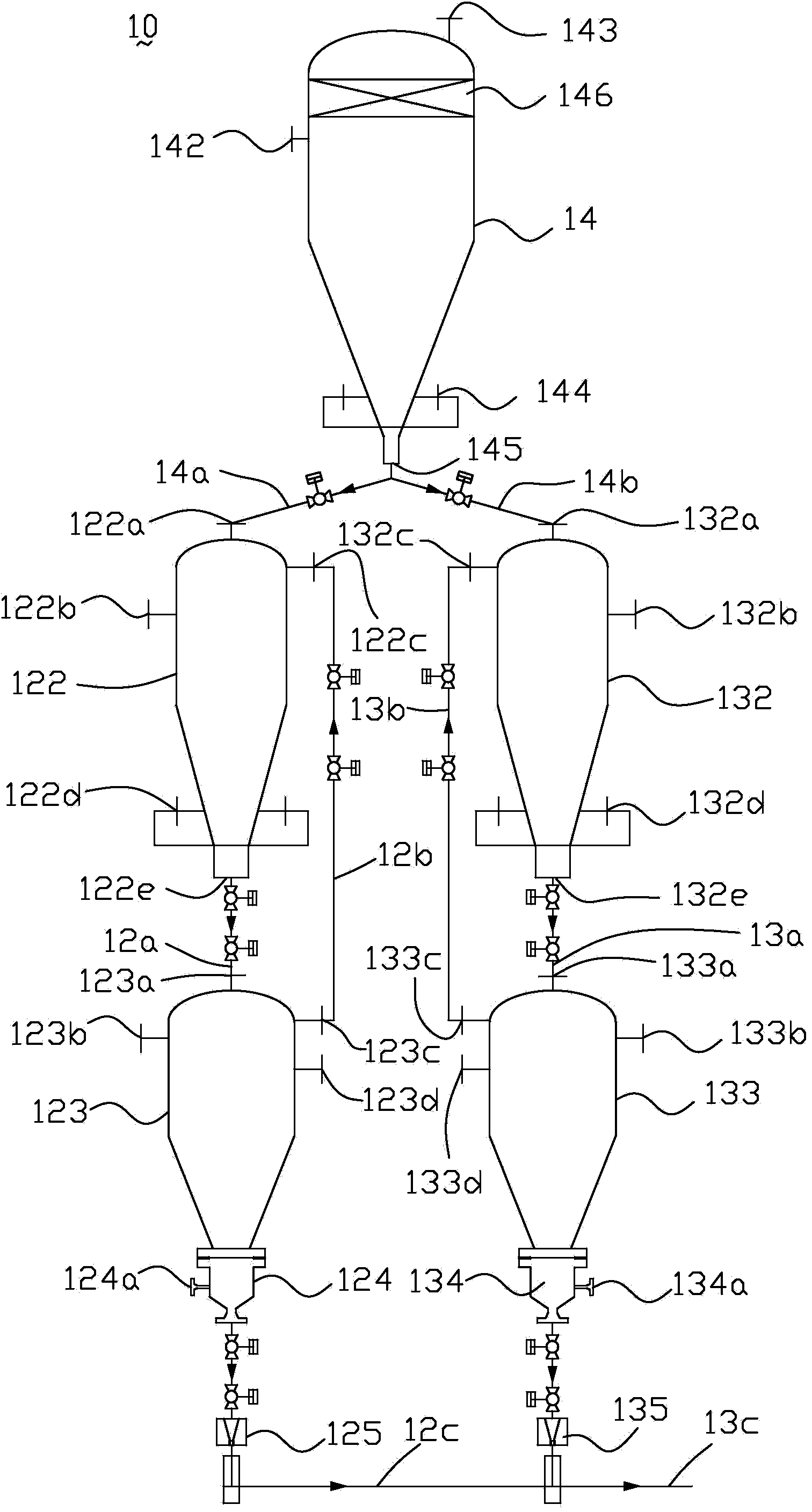

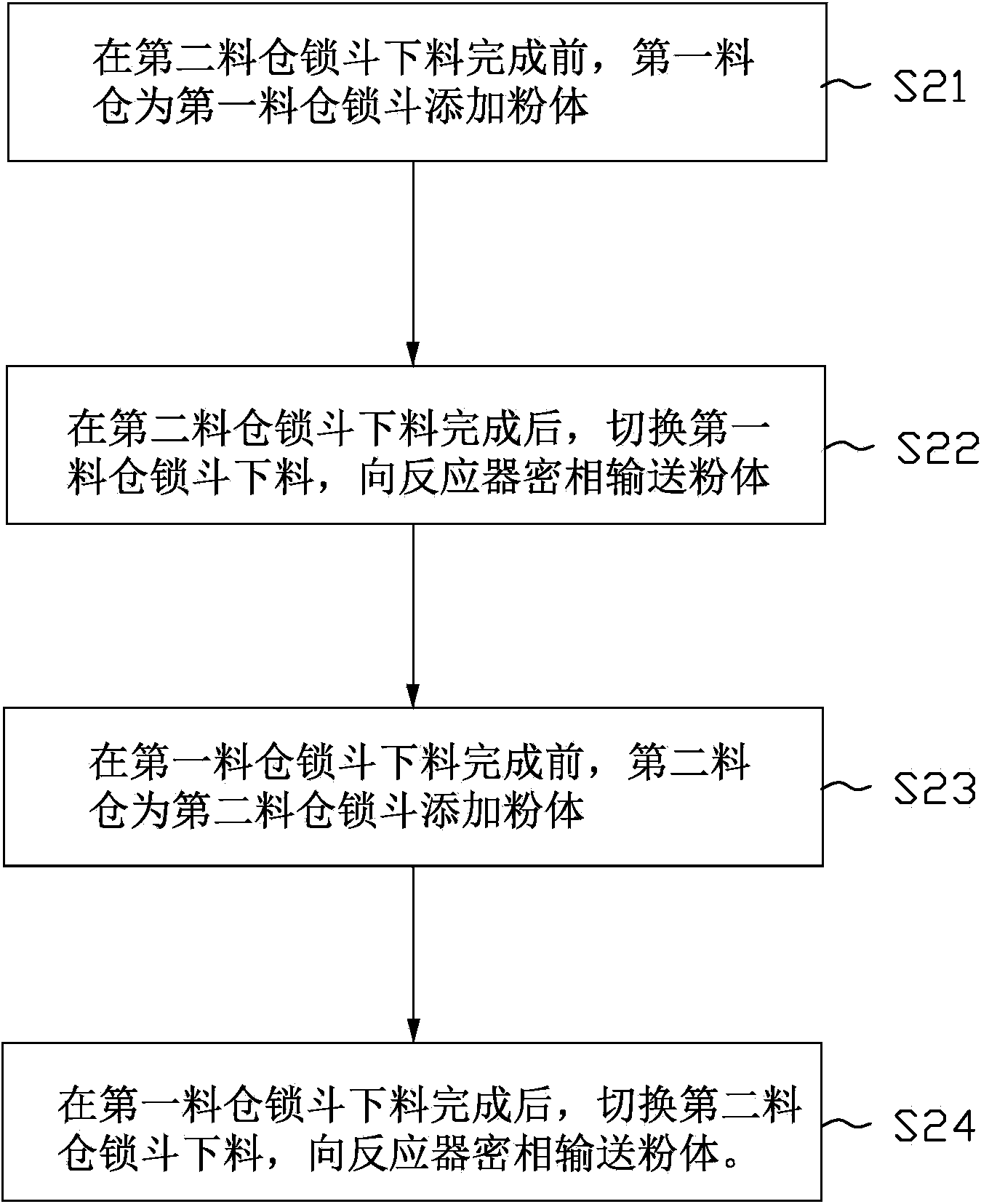

[0024] figure 1 Shown is a schematic diagram of the structure of the dense-phase conveying system of the embodiment of the present invention. figure 2 shown as figure 1 Schematic diagram of the dense-phase transport system. See figure 1 with figure 2 , the dense-phase conveying system 10 of this embodiment is used to transport the powder to a reactor 101. In this embodiment, the powder is pulverized coal. After the pulverized coal enters the reactor 101, under a certain temperature and pressure, It reacts chemically with oxidants and turns into gas. It should be noted that in the present invention, the type of powder is not limited.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com