Band-sawing machine for carpenters

A band saw machine and woodworking technology, which is applied in the direction of band saws, wood processing equipment, sawing equipment, etc., can solve the problems that cannot fully meet the needs of use, there is no saw wheel to adjust the tension device, and the guide is easy to cause deviation, etc., to achieve good results. Economic and social benefits, good orientation, and the effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

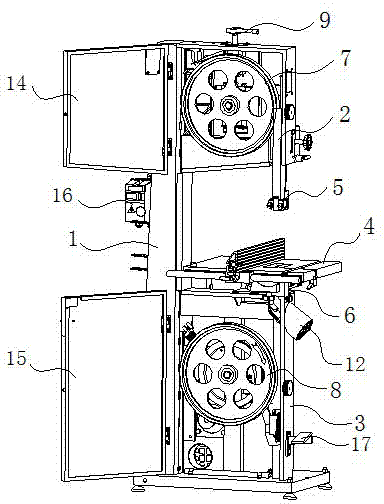

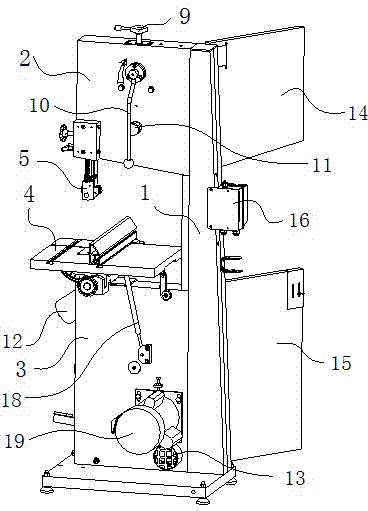

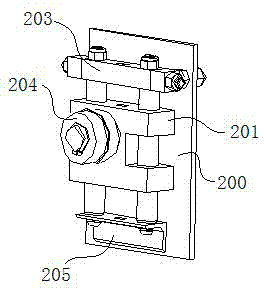

[0023] Such as figure 1 and figure 2 As shown, the woodworking band saw machine, the main components include frame 1, upper guard 2, lower guard 3, workbench 4, upper saw card 5, lower saw card 6, upper wheel 7, lower wheel 8, adjustment handle 9 , Quick tensioning handle 10, adjusting nut 11, upper chip outlet 12, lower chip outlet 13, upper door 14, lower door 15, electromagnetic switch 16, foot brake 17, gas spring 18, motor 19 and saw blade 20, etc. Set upper guard 2, lower guard 3 and workbench 4 on frame 1, workbench 4 is positioned between upper guard 2 and lower guard 3; 3 is provided with a lower wheel 8, the upper guard 2 is connected with the upper saw card 5, the lower guard 3 is connected with the lower saw card 6, the saw blade 20 is set between the upper wheel 7 and the lower wheel 8, and passes through the upper saw card 5 , Lower the saw card 6. U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com