Numerical control machine tool for dual-blade blind hole fixed depth machining

A CNC machine tool and deep processing technology, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of inability to guarantee straightness, low processing efficiency, insufficient processing depth, etc., to reduce processing and transportation difficulties, improve Processing efficiency, the effect of facilitating the alignment of the first hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

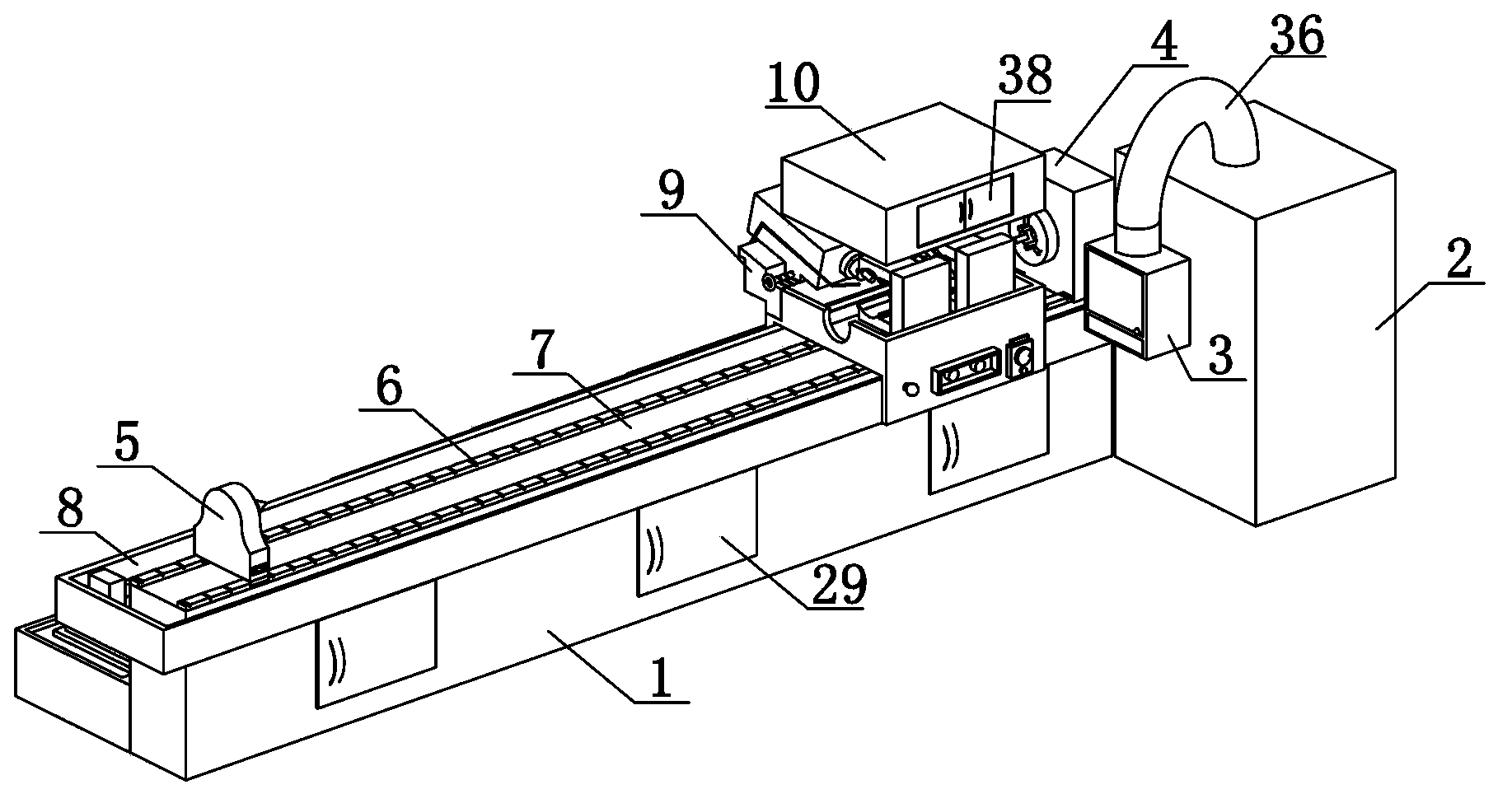

[0026] Embodiment 1 of the present invention: as figure 1 As shown, a double-knife blind hole fixed-depth processing CNC machine tool includes a bed 1, a machine tool electrical cabinet 2, a CNC control panel 3, a clamping table 4, a tailstock 5, a double-knife fixed-depth processing device 9, and a machine tool electrical cabinet 2 Located on one side of the bed 1, the electrical cabinet 2 of the machine tool is connected to the CNC control panel 3 through a rotating rod 36. The upper end of the bed 1 is provided with a clamping table 4, and the bed 1 is provided with a track table 7, and on the track table 7 A track 6 is provided, a tailstock 5 and a double-knife depth-fixing processing device 9 are arranged on the track 6, the tailstock 5 is adjusted to a position 2.3 meters away from the clamping table 4, and the tailstock 5 is locked on the track table 7 by bolts.

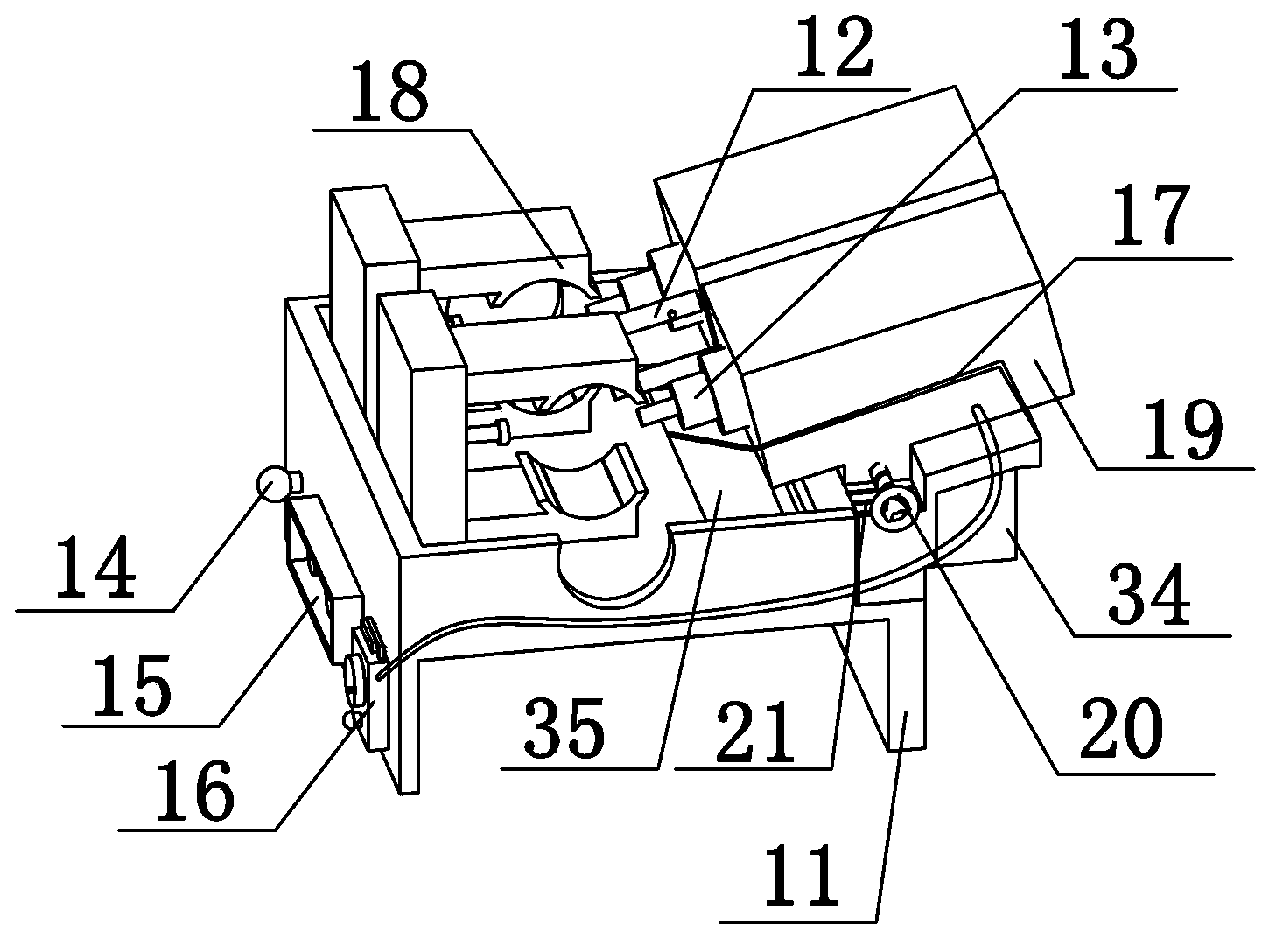

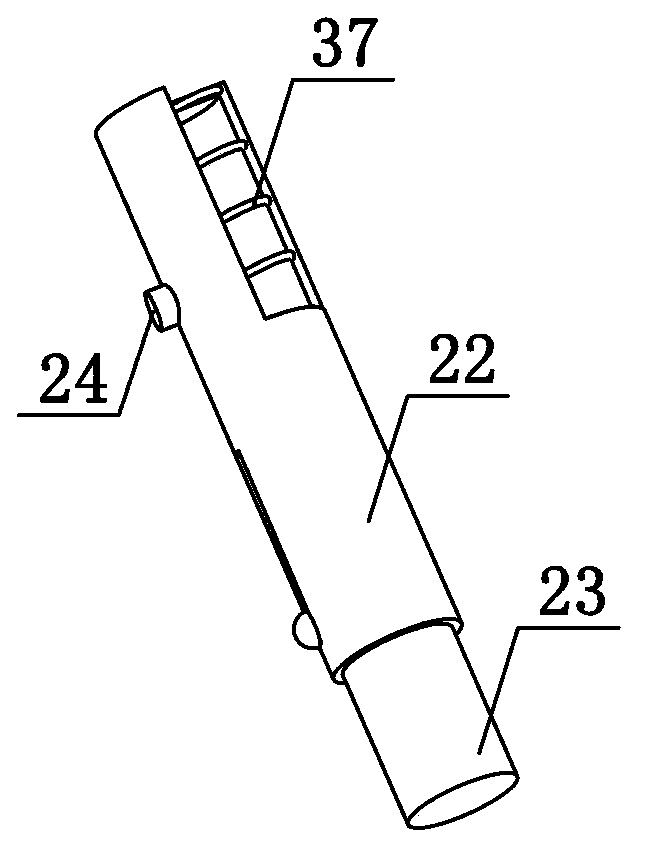

[0027] The bed 1 is provided with a cutting fluid replacement port 29, and the double-knife fixed-depth pro...

Embodiment 2

[0036] Embodiment 2 of the present invention: as figure 1 As shown, a double-knife blind hole fixed-depth processing CNC machine tool includes a bed 1, a machine tool electrical cabinet 2, a CNC control panel 3, a clamping table 4, a tailstock 5, a double-knife fixed-depth processing device 9, and a machine tool electrical cabinet 2 Located on one side of the bed 1, the electrical cabinet 2 of the machine tool is connected to the CNC control panel 3 through a rotating rod 36. The upper end of the bed 1 is provided with a clamping table 4, and the bed 1 is provided with a track table 7, and on the track table 7 A track 6 is provided, a tailstock 5 and a double-knife depth-fixing processing device 9 are arranged on the track 6, the tailstock 5 is adjusted to a position 3.4 meters away from the clamping table 4, and the tailstock 5 is locked on the track table 7 by bolts.

[0037] The bed 1 is provided with a cutting fluid replacement port 29, and the double-knife fixed-depth pro...

Embodiment 3

[0046] Embodiment 3 of the present invention: as figure 1 As shown, a double-knife blind hole fixed-depth processing CNC machine tool includes a bed 1, a machine tool electrical cabinet 2, a CNC control panel 3, a clamping table 4, a tailstock 5, a double-knife fixed-depth processing device 9, and a machine tool electrical cabinet 2 Located on one side of the bed 1, the electrical cabinet 2 of the machine tool is connected to the CNC control panel 3 through a rotating rod 36. The upper end of the bed 1 is provided with a clamping table 4, and the bed 1 is provided with a track table 7, and on the track table 7 There is a track 6, the tailstock 5 and the double-knife depth-fixing processing device 9 are arranged on the track 6, the tailstock 5 is adjusted to a position 4.6 meters away from the clamping table 4, and the tailstock 5 is locked on the track table 7 by bolts.

[0047] The bed 1 is provided with a cutting fluid replacement port 29, and the double-knife fixed-depth pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com