Catalyst for methanol or dimethyl ether carbonylation synthesis of methyl acetate, preparation method and application thereof

A technology of methyl acetate and catalyst, applied in the field of synthesis of methyl acetate, can solve the problems of low catalyst activity, poor catalyst stability and the like, and achieve the effects of high selectivity, good stability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

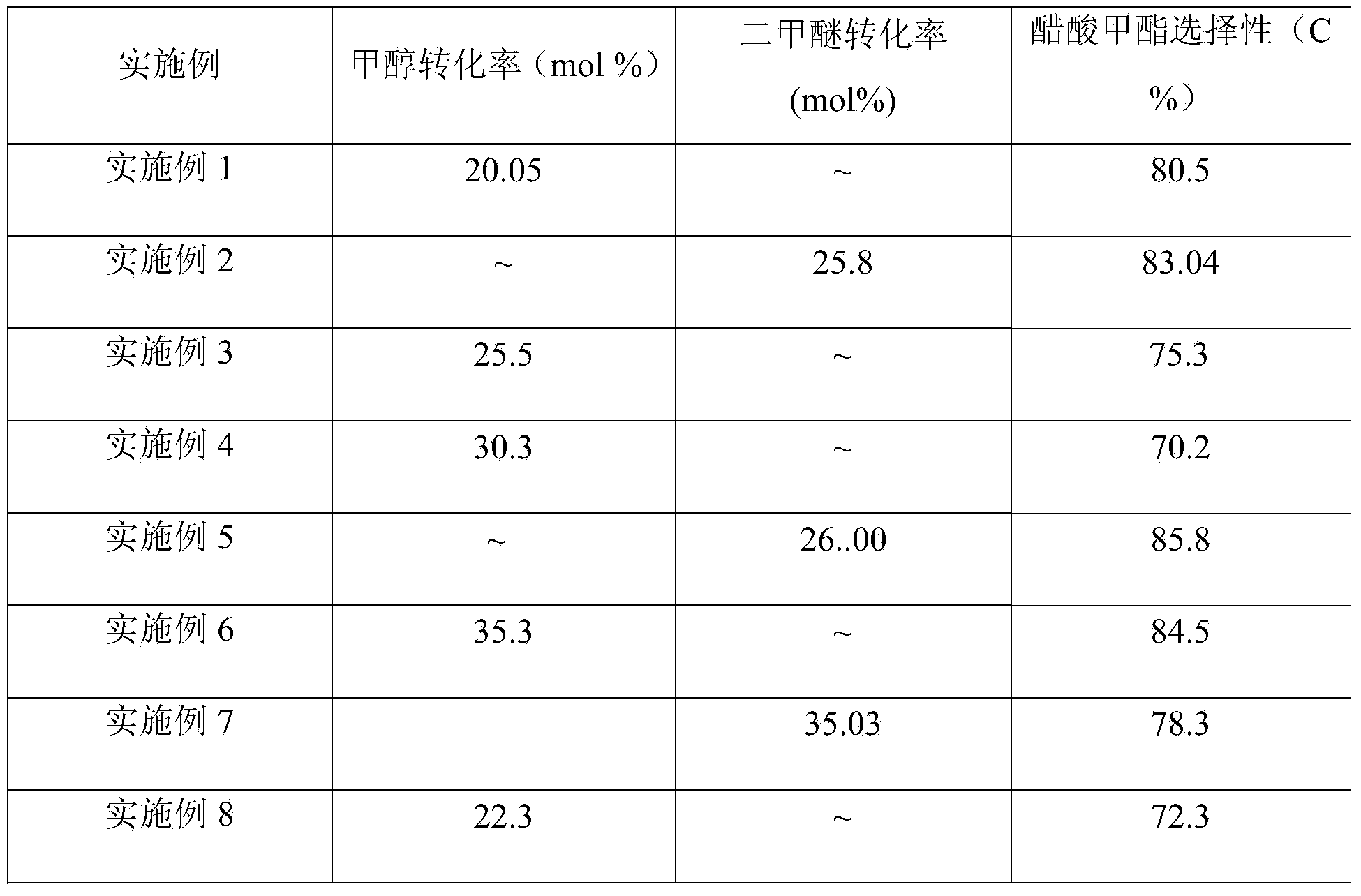

Examples

Embodiment 1

[0021] Mix 33.6ml TEOS, 46.2ml TPAOH (0.68M) aqueous solution and 3.9ml deionized water, stir at room temperature for 2h until complete hydrolysis, and obtain solution A. Dissolve 1.02g TBOT in 11.4ml IPA, add 19.3ml TPAOH (0.68M) aqueous solution and 16.6ml deionized water, stir at room temperature for 40min to obtain a clear light yellow hydrolyzate B. Mix and stir the two hydrolyzates A and B evenly, then stir at 50°C for 3 hours to remove the alcohol in the system, and at the same time replenish deionized water to keep the volume of the glue constant, and then put it into a stainless steel crystallizer with a polytetrafluoroethylene liner In the kettle, it was aged at 80°C for 27 hours to obtain Sol 1. Take 6.0g of DDA and dissolve it in a mixed solution composed of 60ml of absolute ethanol and 60ml of deionized water, add the sol 1 prepared in the first step, and adjust the pH of the system to 10 with hydrochloric acid. The resulting mixture was continuously stirred at r...

Embodiment 2

[0025] Mix 20ml TEOS, 25.2ml TPAOH (0.68M) aqueous solution and 3.5ml deionized water, stir at room temperature for 1 hour until complete hydrolysis, and obtain solution A. Dissolve 1.25g TBOT in 9.8ml IPA, add 17ml TPAOH (0.68M) aqueous solution and 9.5ml deionized water, stir at room temperature for 30min to obtain clear light yellow hydrolyzate B. Mix and stir the two hydrolyzates A and B evenly, then stir at 40°C for 3 hours to remove the alcohol in the system, and at the same time replenish deionized water to maintain a constant volume of the glue, and then put it into a stainless steel crystallizer with a polytetrafluoroethylene liner In the kettle, it was aged at 80°C for 30 hours to obtain Sol 1.

[0026] Dissolve 3.3g of DDA in a mixed solution of 30ml of absolute ethanol and 32ml of deionized water, add the sol 1 prepared in the first step, and adjust the pH of the system to 11 with hydrochloric acid. The resulting mixture was continuously stirred at room temperatur...

Embodiment 3

[0030]Mix 20ml TEOS, 25.2ml TPAOH (0.68M) aqueous solution and 9ml deionized water, stir at room temperature for 1 hour until complete hydrolysis, and obtain solution A. Dissolve 0.5g TBOT in 5.6ml IPA, add 9.5ml TPAOH (0.68M) aqueous solution and 8.5ml deionized water, stir at room temperature for 30min to obtain a clear light yellow hydrolyzate B. Mix and stir the two hydrolyzates A and B evenly, then stir at 45°C for 2 hours to remove the alcohol in the system, and supplement deionized water at the same time to keep the volume of the glue constant, and then put it into a stainless steel crystallizer with a polytetrafluoroethylene liner In the kettle, it was aged at 140°C for 6 hours to obtain Sol 1.

[0031] Dissolve 3.5g of DDA in a mixed solution of 35ml of absolute ethanol and 34ml of deionized water, add the sol 1 prepared in the first step, and adjust the pH of the system to 9.5 with hydrochloric acid. The resulting mixture was continuously stirred at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com