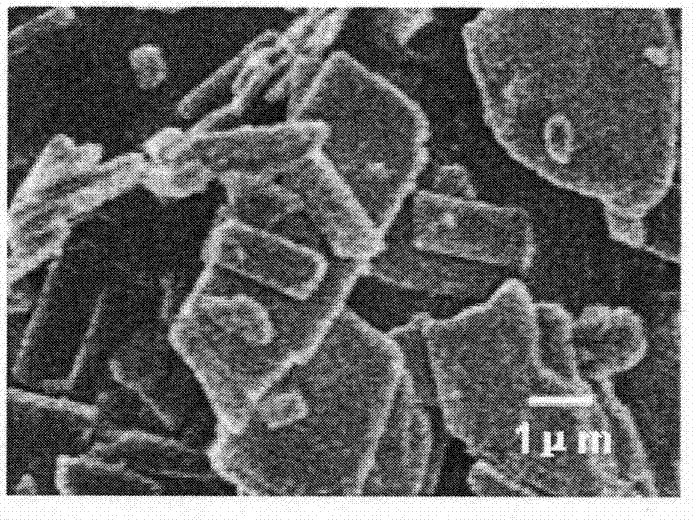

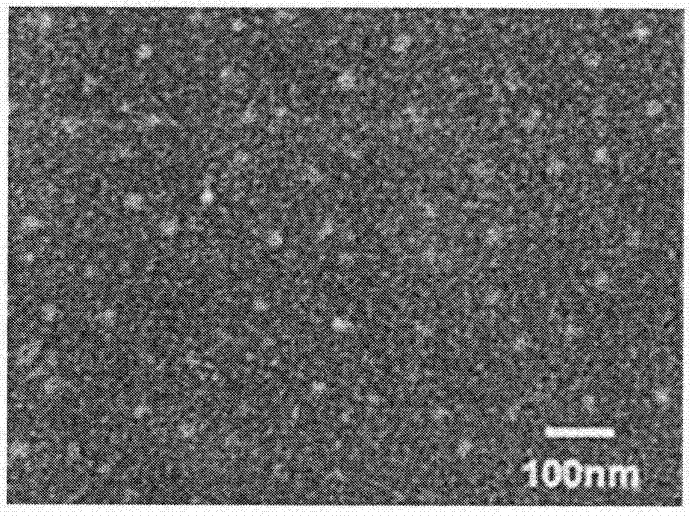

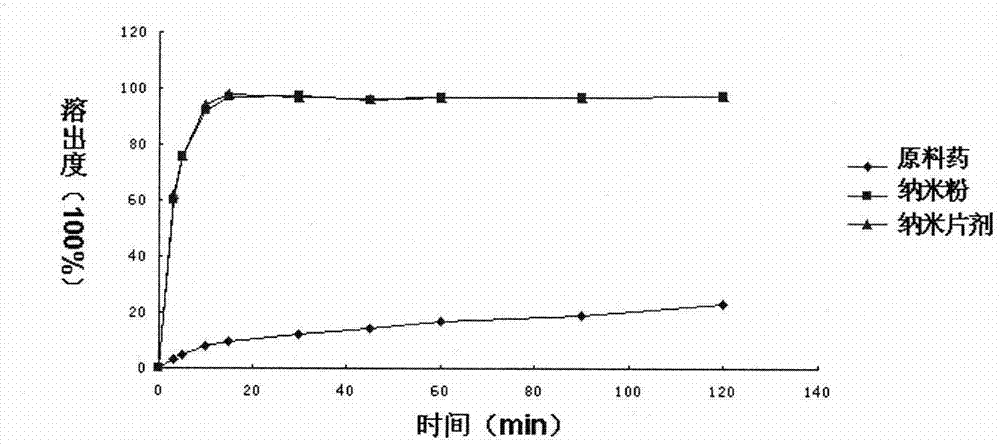

Nano ibuprofen dry powder, tablets and preparation method thereof

A nano-powder and tablet technology, which is applied in anti-inflammatory agents, pill delivery, pharmaceutical formulations, etc., can solve the problems of ibuprofen's poor water solubility, oral absorption and low bioavailability, and achieve improved curative effect and high dissolution rate , the effect of high drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A: Weigh 10g of ibuprofen and dissolve it in 50ml of ethanol;

[0030] B: Weigh 10g of polyvinylpyrrolidone, 5g of polyethylene glycol, 100g of hydroxypropyl methylcellulose, 3g of poloxamer, 3g of oleic acid and 3g of sodium oleate, and dissolve them in 500ml of distilled water;

[0031] C: slowly drop the ethanol solution of ibuprofen into the above-mentioned 500ml mixed solution; high-speed stirring reaction at room temperature to obtain ibuprofen nano-suspension;

[0032] D: The dry powder is obtained by spray drying with a spray dryer. Set the inlet temperature to 120°C, the outlet temperature to 80°C, the feed flow rate to 5ml / min, and the compressed air pressure to 0.6Mpa;

[0033] E: Add appropriate amount of excipients to the dry powder and press it into tablets. Take 1g of the ibuprofen nano-powder obtained in step D, mix with 0.6g of starch, 0.18g of micropowder silica gel, and 0.1g of CMS-Na, add 1.2g of 15% starch slurry to make a soft material, pass throu...

Embodiment 2

[0035] A: Weigh 10g of ibuprofen and dissolve it in 50ml of ethanol;

[0036] B: Weigh 10g of polyvinylpyrrolidone, 10g of polyethylene glycol, 90g of hydroxypropyl methylcellulose, 5g of poloxamer and 5g of sodium oleate, and dissolve them in 500ml of distilled water;

[0037] C: slowly drop the ethanol solution of ibuprofen into the above-mentioned 500ml mixed solution; high-speed stirring reaction at room temperature to obtain ibuprofen nano-suspension;

[0038] D: The dry powder is obtained by spray drying with a spray dryer, the inlet temperature is 140°C, the outlet temperature is 80°C, the feed flow rate is 10ml / min, and the compressed air pressure is 0.4Mpa;

[0039] E: Add appropriate amount of excipients to the dry powder and press it into tablets. Take 1g of the ibuprofen nano-powder obtained in step D, mix with 0.6g of starch, 0.18g of micropowder silica gel, and 0.1g of CMS-Na, add 1.2g of 15% starch slurry to make a soft material, pass through a 16-mesh sieve to...

Embodiment 3

[0041] A: Weigh 10g of ibuprofen and dissolve it in 50ml of ethanol;

[0042] B: Weigh 20g of polyvinylpyrrolidone, 10g of polyethylene glycol, 80g of hydroxypropyl methylcellulose, 5g of poloxamer, 3g of lecithin and 3g of sodium oleate, and dissolve them in 500ml of distilled water;

[0043] C: slowly drop the ethanol solution of ibuprofen into the above-mentioned 500ml mixed solution; high-speed stirring reaction at room temperature to obtain ibuprofen nano-suspension;

[0044] D: The dry powder is obtained by spray drying with a spray dryer. Set the inlet temperature to 120°C, the outlet temperature to 80°C, the feed flow rate to 10ml / min, and the compressed air pressure to 0.6Mpa.

[0045] E: Add appropriate amount of excipients to the dry powder and press it into tablets. Take 1g of the ibuprofen nano-powder obtained in step D, mix with 0.6g of starch, 0.18g of micropowder silica gel, and 0.1g of CMS-Na, add 1.2g of 15% starch slurry to make a soft material, pass throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com