Lipoic acid tablets with few types and small dose of accessories and preparation method thereof

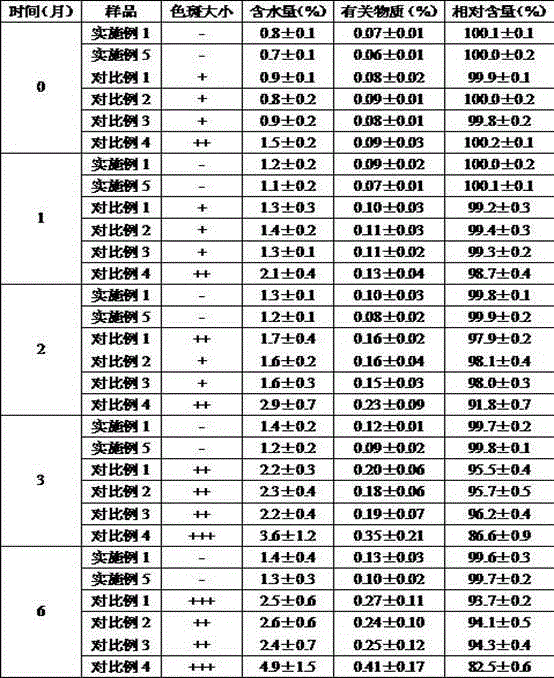

A technology of lipoic acid tablets and excipient tablets, which can be applied to medical preparations with no active ingredients, medical preparations containing active ingredients, and devices that make medicines into special physical or ingestible forms, and can solve the problem of stains that are prone to appear , easy sticking and other problems, to achieve the effect of reducing the dosage of a single dose, reducing the cost of raw materials, and improving the uniformity of color and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of excipient tablets Weigh 1.5kg of starch and 0.15kg of hydroxypropyl cellulose to prepare excipient tablets with a diameter of 5mm-6mm according to the method of wet granulation and tabletting;

[0032] (2) Spray the main drug layer. Put the prepared auxiliary material tablet in a high-efficiency coating pan, weigh 8.5kg of lipoic acid and sieve it, and spray the sodium carboxymethyl cellulose solution with a concentration of 1%-1.5% with a spray gun. As a spray, spray the sieved lipoic acid powder layer by layer on the auxiliary material sheet, the rotation speed of the high-efficiency coating pan is 40 rpm, the air inlet temperature is 30°C-35°C, and the spray gun pressure is 0.4MPa. 120 layers, dried at 30°C-35°C for 35 minutes, then placed in a constant temperature room at 20°C-30°C for 6 hours to dry.

Embodiment 2

[0034] (1) Preparation of excipient tablets Weigh 3.0kg of dextrin and 0.25kg of starch slurry to prepare excipient tablets with a diameter of 5mm-6mm by dry granulation and tabletting;

[0035] (2) Spray the main drug layer. Put the prepared auxiliary material tablet in a high-efficiency coating pan, weigh 6.5kg of lipoic acid and sieve it, and spray the sodium carboxymethyl cellulose solution with a concentration of 1%-1.5% with a spray gun. As a spray, spray the sieved lipoic acid powder layer by layer on the auxiliary material sheet, the rotation speed of the high-efficiency coating pan is 45 rpm, the air inlet temperature is 30°C-35°C, and the pressure of the spray gun is 0.5MPa. 100 layers, dried at 30°C-35°C for 45 minutes, then placed in a constant temperature room at 20°C-30°C for 8 hours to dry.

Embodiment 3

[0037] (1) Preparation of excipient tablets Weigh 2.0kg of lactose and 0.2kg of hypromellose to prepare excipient tablets with a diameter of 5mm-6mm according to the direct powder compression method;

[0038](2) Spray the main drug layer. Put the prepared auxiliary material tablet in a high-efficiency coating pan, weigh 8.0kg of lipoic acid and sieve it, and use a spray gun to spray the sodium carboxymethyl cellulose solution with a concentration of 1%-1.5%. As a spray, spray the sieved lipoic acid powder layer by layer on the auxiliary material sheet, the rotation speed of the high-efficiency coating pan is 45 rpm, the air inlet temperature is 30°C-35°C, and the spray gun pressure is 0.45MPa. 115 layers, dried at 30°C-35°C for 40 minutes, then placed in a constant temperature room at 20°C-30°C for 7 hours to dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com