Curable epoxy resin composition

A technology of epoxy resin and composition, applied in the direction of electric solid devices, instruments, electrical components, etc., can solve the problems of yellowing over time, unable to maintain light reflectivity, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0281]

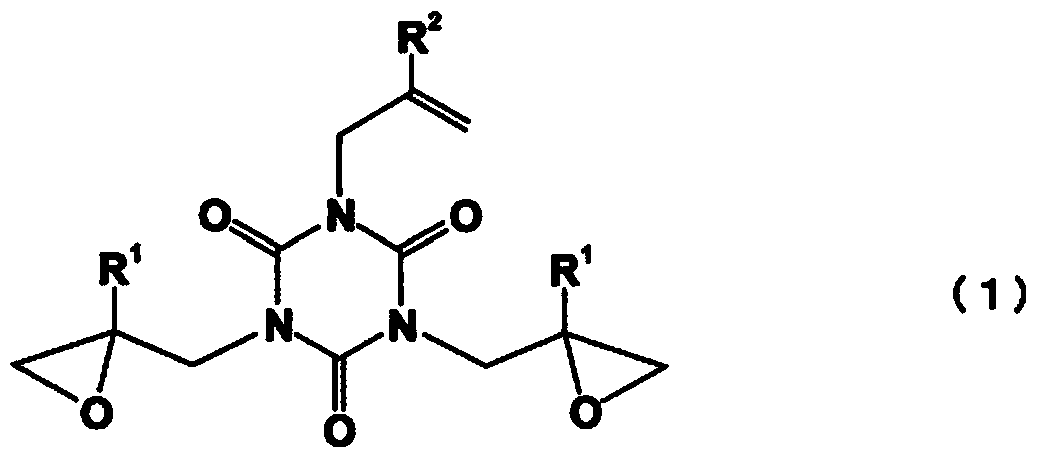

[0282] It does not specifically limit as a manufacturing method of the curable epoxy resin composition of this invention, A well-known and usual method can be applied. Specifically, for example, a given amount of alicyclic epoxy compound (A), monoallyl diglycidyl isocyanurate compound (B), white pigment (C), curing agent (D ), curing accelerator (F) and any additives, or a given amount of cycloaliphatic epoxy compound (A), monoallyl diglycidyl isocyanurate compound (B), white pigment (C ), curing catalyst (E) and optional additives, and using various mixers such as dissolving rods and homogenizers, kneaders, rollers, bead mills, self-rotating and revolving stirring devices, etc. to stir and mix. In addition, after stirring and mixing, defoaming may be performed under reduced pressure or vacuum.

[0283] More specifically, the curable epoxy resin composition of the present invention can be prepared, for example, by the following method: separately prepare Compound ...

manufacture example 1

[0303] (Manufacture of white pigment-containing epoxy resin: Examples 1-9)

[0304] Monoallyl diglycidyl isocyanurate (manufactured by Shikoku Chemical Industry Co., Ltd., trade name "MA-DGIC"), An alicyclic epoxy compound (manufactured by Daicel, trade name "CELLOXIDE 2021P") was mixed and stirred at 80°C for 1 hour to dissolve monoallyl diglycidyl isocyanurate to obtain a cycloaliphatic epoxy compound. Oxygen resin (mixture). Next, according to the compounding recipe (mixing ratio) (unit: parts by weight) shown in Table 1, the above-mentioned epoxy resin and white pigment (titanium oxide; manufactured by Seika Kogyo Co., Ltd., trade name "TCR-52") were mixed using a dissolving rod. ”) were uniformly mixed, and kneaded using a roller mill under given conditions (roll distance: 0.2 mm, rotational speed: 25 Hz, 3 paths) to obtain an epoxy resin (epoxy resin composition) containing a white pigment.

manufacture example 2

[0306] (Manufacture of white pigment-containing epoxy resin: Comparative Examples 1 to 8)

[0307] Alicyclic epoxy compound (trade name "CELLOXIDE2021P", manufactured by Daicel; trade name "EHPE3150", manufactured by Daicel) according to the formula (mixing ratio) (unit: parts by weight) shown in Table 1 manufactured), triglycidyl isocyanurate (trade name "TEPIC-PAS B26", manufactured by Nissan Chemical Industry Co., Ltd.) to obtain epoxy resin (mixture) (in comparative examples 1, 2, 4 to In the case of 6 and 8, since the epoxy resin component is one kind, this mixing is not performed, and it is used as an epoxy resin as it is). Next, according to the compounding recipe (mixing ratio) (unit: parts by weight) shown in Table 1, the above-mentioned epoxy resin and white pigment (titanium oxide; trade name "TCR-52", Kai Chemical Industry Co., Ltd. system) were uniformly mixed and kneaded using a roller mill under given conditions (roll distance: 0.2mm, rotational speed: 25 Hz, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com