An ionization sensor based on a micro-gap polarization structure to construct a discharge electric field

A structural structure and sensor technology, applied in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve the problems of difficult materials with large aspect ratios, high random components of signals, and small sampling space, and reduce contamination failure. The probability of increasing the signal-to-noise ratio and sensitivity, and the effect of increasing the sampling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

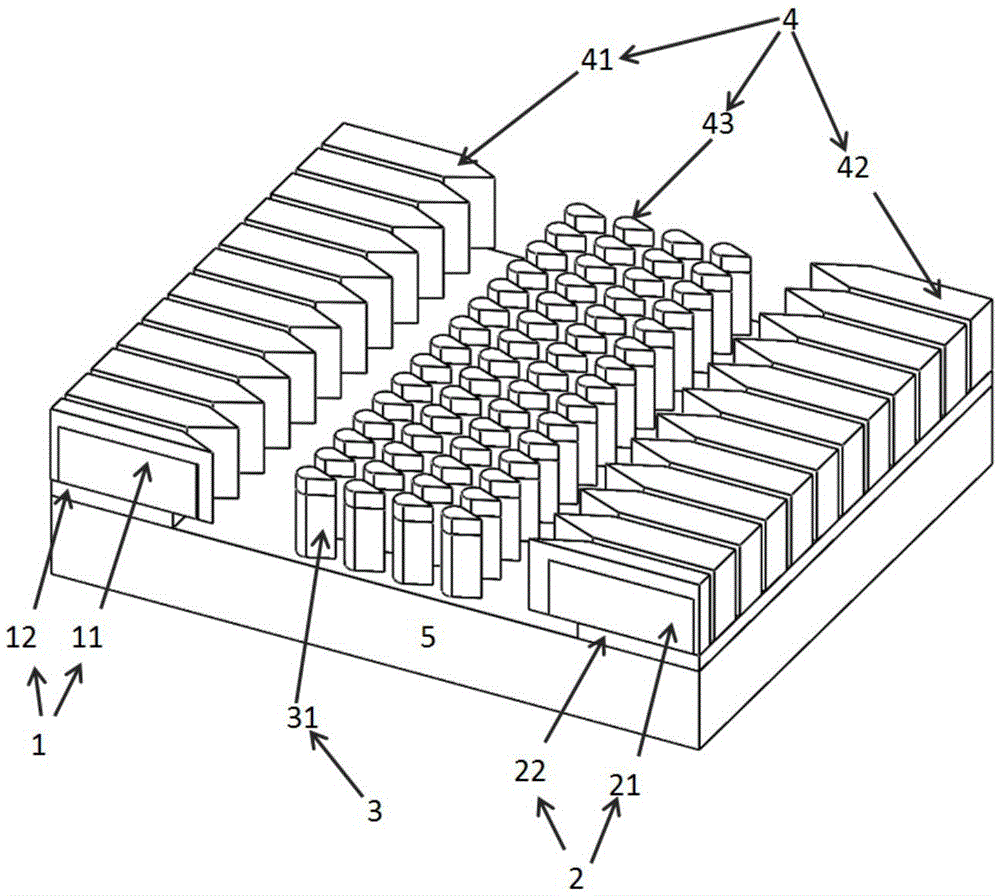

[0063] Such as figure 1 As shown, an ionization sensor that constructs a discharge electric field based on a micro-gap polarization structure includes: a copper first external circuit electrode 1, a copper second external circuit electrode 2, a copper polarization structure 3, and a large aspect ratio Material 4 and glass substrate 5; wherein, the polarization structure 3 is arranged between the first external circuit electrode 1 and the second external circuit electrode 2, and the large aspect ratio material 4 is arranged between the first external circuit electrode 1 and the second external circuit electrode The entire surface of the electrode 2 is disposed on a part of the surface of the polarized structure 3 ; the first external circuit electrode 1 , the second external circuit electrode 2 and the polarized structure 3 are disposed on the substrate 5 .

[0064] Between the first external circuit electrode 1 and the polarized structure 3, there is a gas gap of 50 microns, b...

Embodiment 2

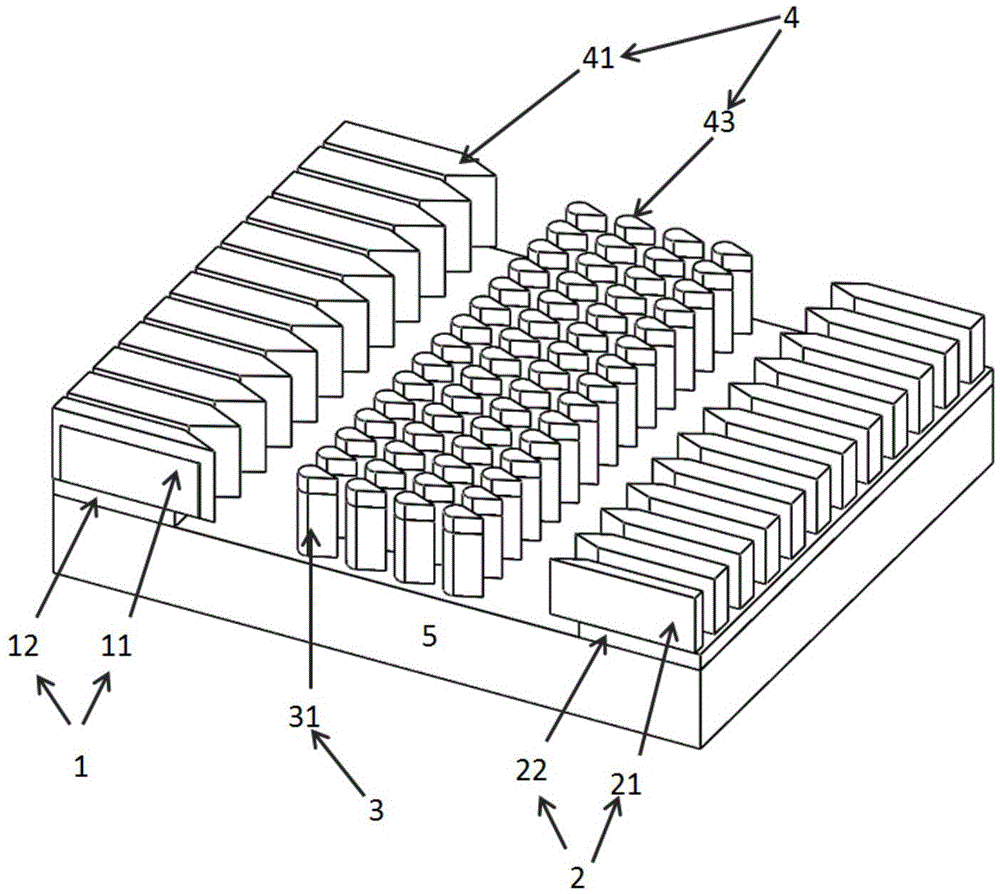

[0080] Such as figure 2 As shown, the technical solution of this embodiment is the same as that of Embodiment 1 except for the following features: the large aspect ratio material 4 is arranged on the entire surface of the first external circuit electrode 1 and is arranged on a part of the surface of the polarized structure 3, Specifically, it is the upper surface and the upper part of the side wall of each structural unit 31 of the polarization structure 3 , and is not arranged on the surface of the second external circuit electrode 2 . In the sensor of this embodiment, the large aspect ratio material 4 is not arranged on the surface of the second external circuit electrode 2, and the present invention does not require the electrode pair and the polarization structure to be provided with a large aspect ratio material, so it is easier to process, and The problem of short circuit is not easy to occur, and it is beneficial to improve the yield and stability of the device.

[00...

Embodiment 3

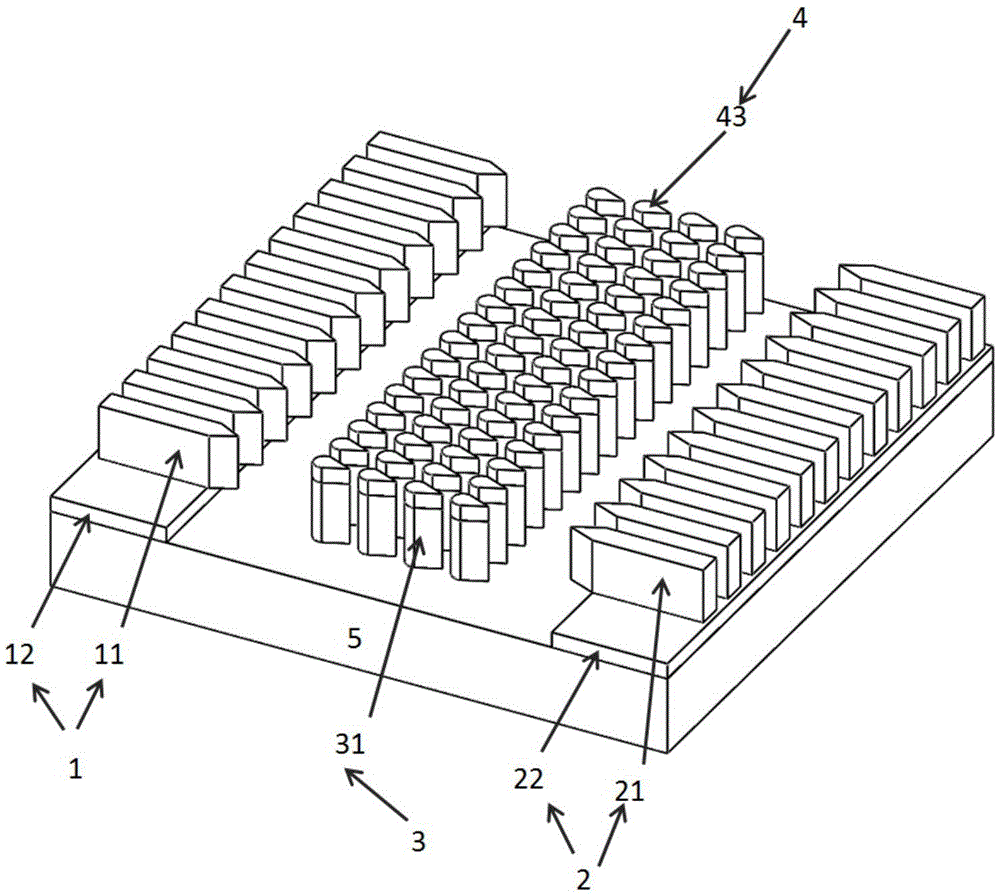

[0084] Such as image 3 As shown, the technical solution of this embodiment is the same as that of Embodiment 1 except for the following features: the large aspect ratio material 4 is not arranged on the surface of the first external circuit electrode 1 and the second external circuit electrode 2, but only on the electrodes. part of the surface of structure 3.

[0085] In the sensor of this embodiment, it is only arranged on a part of the surface of the polarized structure 3, and the present invention does not require materials with a large aspect ratio to be arranged on the electrode pairs and the polarized structure, nor does it require to be arranged on all of the electrode pairs or the polarized structure. surface and thus easier to process.

[0086] The first external circuit electrode 1 and the second external circuit electrode 2 of the sensor are respectively connected to the test terminal positive pole and negative pole of the Agilent B2911A volt-ampere characteristic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com