Online thickness monitor and online thickness monitoring method

A monitoring instrument and cable technology, applied in the field of online thickness monitoring instrument and online thickness monitoring, can solve the problem of difficulty in guaranteeing height measurement accuracy, and achieve the effect of saving rework and repair costs, strengthening the ability, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the electronics manufacturing industry, in the early stage of circuit board assembly, the height of the solder paste is measured from the solder paste coating process to realize early monitoring of the process quality:

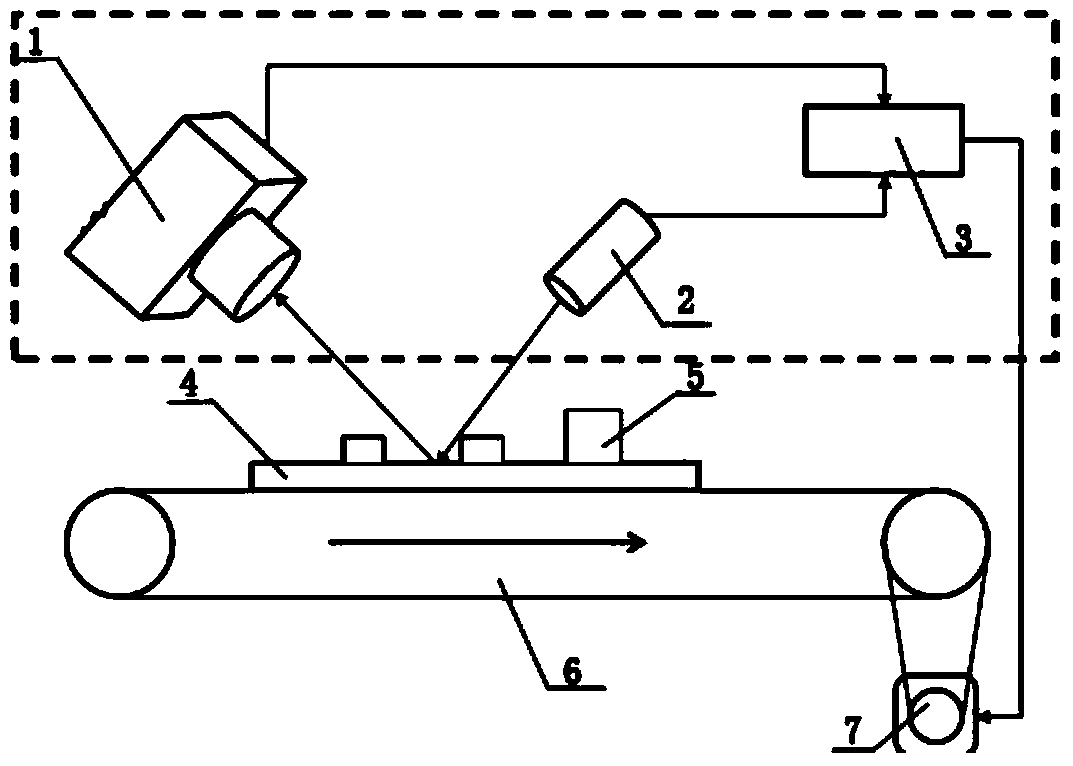

[0029] An online thickness monitor, comprising a CCD industrial camera 1, a laser 2, a microprocessor 3 and an interface cable, the CCD industrial camera 1 and the laser 2 are respectively connected to the microprocessor 3 through an interface cable, and connected to the microprocessor device 3 for information interaction;

[0030] Described microprocessor 3 is also connected with driving motor 7, is used for controlling the rotating speed of driving motor 7;

[0031] The laser 2 and the CCD industrial camera 1 are respectively installed at an angle of 45° to the reference plane 4, the laser 2 emits a laser beam, the CCD industrial camera 1 captures the reflected beam, and the laser beam emitted by the laser 2 is reflected by the reference plane 4, ...

Embodiment 2

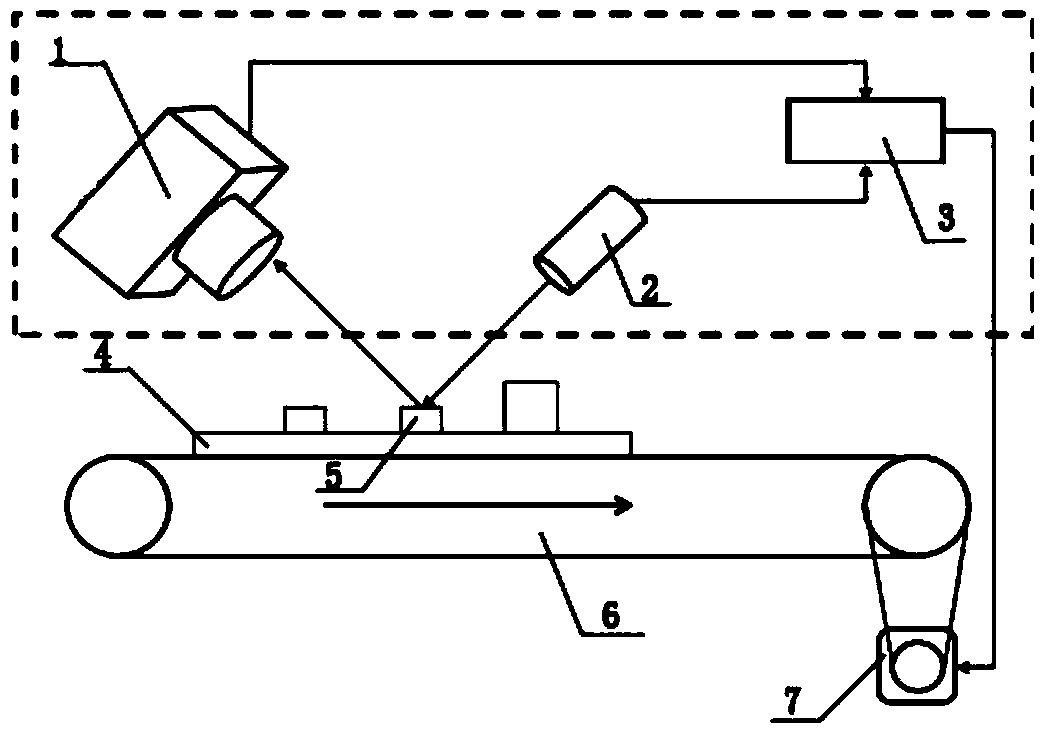

[0041] On the pharmaceutical production line, the height of the pills is monitored:

[0042] An online thickness monitor, comprising a CCD industrial camera 1, a laser 2, a microprocessor 3 and an interface cable, the CCD industrial camera 1 and the laser 2 are respectively connected to the microprocessor 3 through an interface cable, and connected to the microprocessor device 3 for information interaction;

[0043] Described microprocessor 3 is also connected with driving motor 7, is used for controlling the rotating speed of driving motor 7;

[0044] The CCD industrial camera 1 and the laser 2 are located on opposite sides;

[0045] Since the height of the pills is very small, adjust the inclined installation angles of the CCD industrial camera 1 and the laser 2 relative to the reference plane 4 to make it less than 45 degrees;

[0046] Transforming formula 1 to get:

[0047] l=h / cosθ (Formula 2)

[0048] Among them: h—the height of the medicine grain; l—the magnificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com