Novel technology for processing dye wastewater by combining advanced oxidation technology with biofilm process

An advanced oxidation technology, dye wastewater technology, applied in the field of dye wastewater treatment, can solve the problems of high energy consumption, complex operation and management, etc., and achieve the effect of low water treatment cost, good treatment effect, and conducive to development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

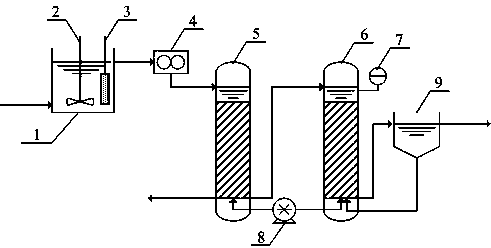

Image

Examples

specific Embodiment

[0069] The present invention will be further described below through specific examples.

example 1

[0071] Take 5L of comprehensive sewage generated from the mother liquor and washing water for the production of acid dyes, neutral dyes, mordant dyes and dye intermediates, and its COD is 4600mg / L for small-scale experiments. (1) Use hydrochloric acid to adjust the pH to 3.46; (2) Add 6.5mL of 30% H 2 O 2 , 1.9 g FeSO 4 ·7H 2 O, stirring at 200rpm for 45min; (3) Use sodium hydroxide to adjust the pH to 7.35; (4) In the biofilm system, fully aerate the dissolved oxygen in the effluent to be greater than 2.0mg / L; (5) The effluent of the biofilm system is in Stand still in the clarifier for 30 minutes, the COD in the supernatant effluent is 76mg / L, and the chroma is 52; (6) After running for 120 hours, carry out air-water combined backwashing for a total of 23 minutes (turn off the water first; then air flush for 5 minutes; Water flushing for 8 minutes; water flushing for 10 minutes), the flow rate of air and water during backwashing is 0.5 L / min.

example 2

[0073] The pilot test of the present invention "A new process for combined treatment of dye wastewater by advanced oxidation technology and biofilm method" was carried out in a certain dye chemical company in Anhui, with a daily treatment water volume of 100L. The water quality of comprehensive dye wastewater is: pH value 5.2, COD 4660 mg / L, salinity 5100 mg / L, chroma 4120 times (tan). Since the pilot test in June 2012, a stable treatment effect has been achieved. The specific process is as follows:

[0074] (1) Adjust the pH to 3.5±0.2 with hydrochloric acid;

[0075] (2) Add 130mL of 30%H 2 O 2 , 38 g FeSO 4 ·7H 2 0, stirring 45min under 200rpm rotating speed;

[0076] (3) Use sodium hydroxide to adjust the pH to 7.35±0.2;

[0077] (4) In the biofilm system, fully aerate (air flow rate 1.5L / min) so that the dissolved oxygen in the effluent water is greater than 2.0mg / L;

[0078] (5) The effluent from the biofilm system was kept still in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com