Biofilm treatment method for aquaculture wastewater

A technology for aquaculture wastewater and membrane treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult treatment, save sludge return system, prolong The effect of sludge age and concentration increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

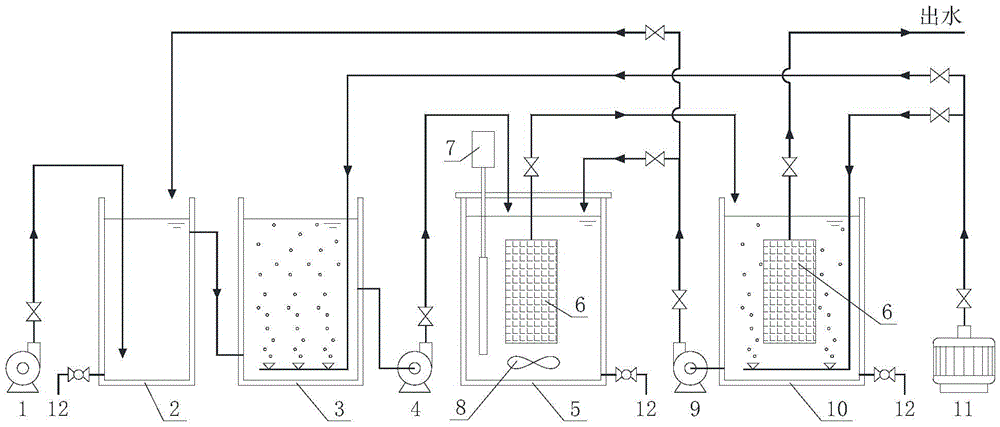

[0018] see figure 1 , the embodiment of the present invention includes the following steps:

[0019] 1) After the raw water is regulated by the regulating tank, it first enters the coagulation tank 2 through the wastewater pump 1 for dosing coagulation pretreatment, and the pretreated aquaculture wastewater enters the air flotation tank 3 for air flotation treatment. The water pump 4 enters the anaerobic tank 5 of the biological treatment system; the coagulation pretreatment time can be 10-120 min; the microbubble diameter of the air flotation tank can be 10-1000 μm; the air flotation treatment time can be 10-120 min ; The membrane module made of industrial filter cloth or absorbent filler is placed in the anaerobic tank, and the industrial filter cloth can be selected from at least one of polyester staple fiber, polyester long fiber, vinylon, polypropylene fiber, etc., the Adsorptive fillers can be selected from at least one of zeolite, quartz sand, etc.; the pore size of th...

Embodiment 2 and 3

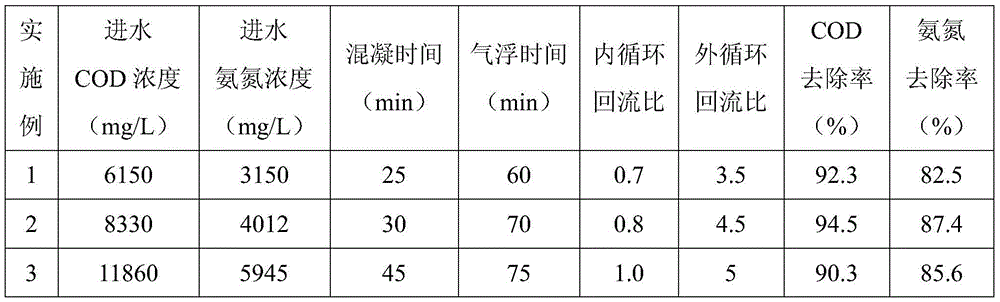

[0026] The specific steps are similar to those in Example 1, the difference is only in the influent COD concentration, influent ammonia nitrogen concentration, coagulation time, air flotation time, internal circulation reflux ratio and external circulation reflux ratio, and the treatment effect of the biochemical membrane treatment process for aquaculture wastewater is shown in the table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com