Dynamic membrane anaerobic-aerobic circular integration sewage treatment method

A sewage treatment method and recycling treatment technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problems of low efficiency, high investment cost, equipment occupation Large area and other problems, to achieve the effect of increased concentration, high operating costs, and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I(1~3)

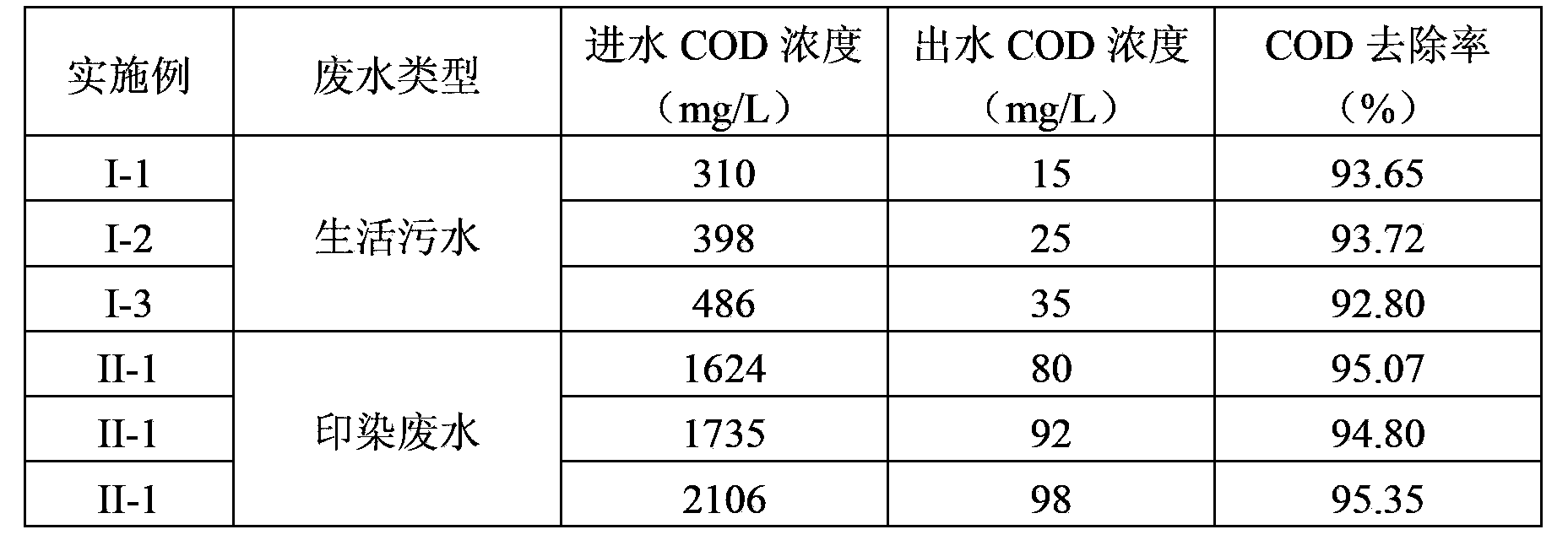

[0023] Type of waste water: Domestic sewage.

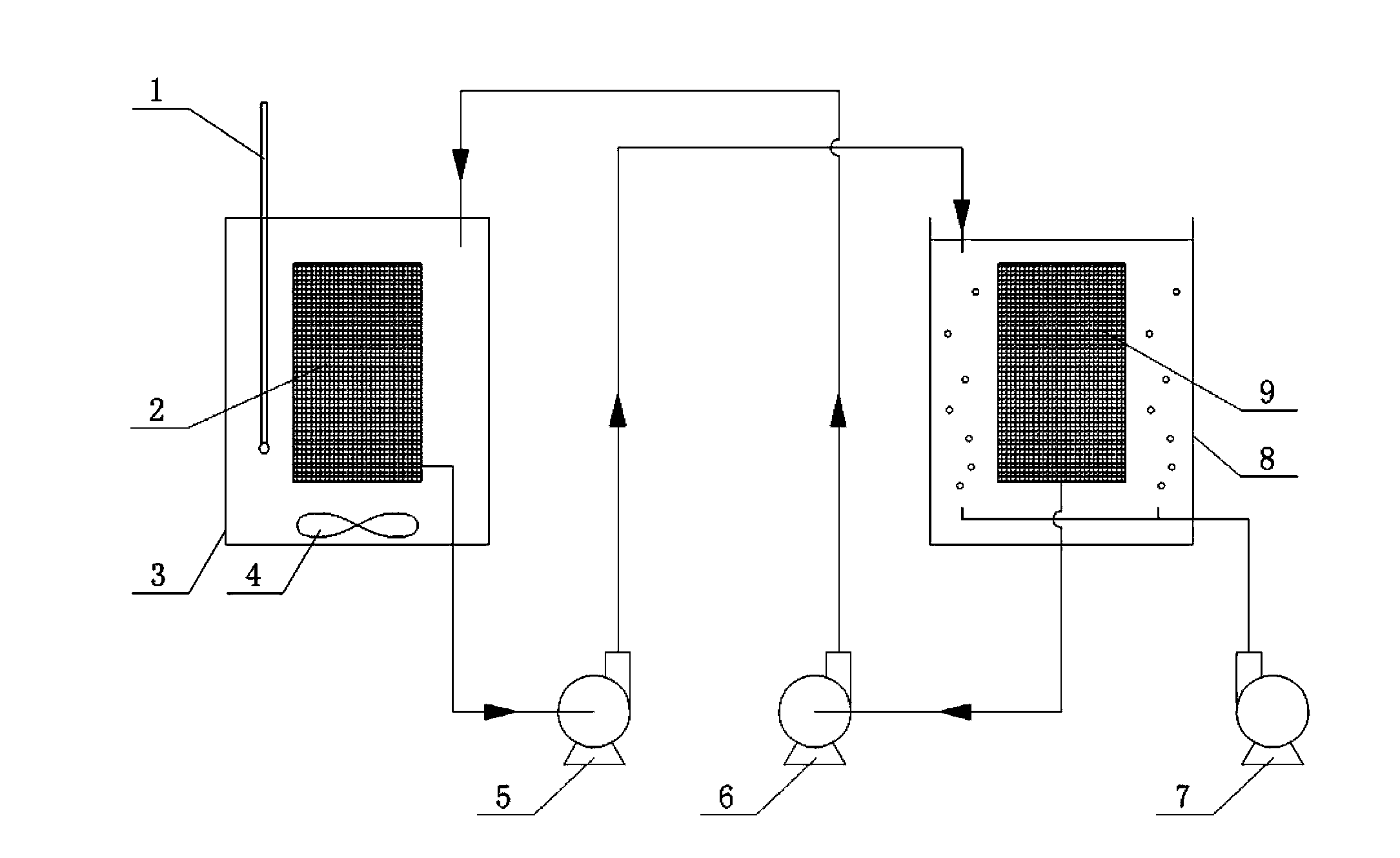

[0024] see figure 1 , the specific steps of the dynamic membrane anaerobic-aerobic cycle integrated sewage treatment method are given below:

[0025] 1) The raw water first enters the anaerobic pool 3 and the aerobic pool 8 of the dynamic membrane anaerobic-aerobic cycle integrated reaction system through the regulating pool. The anaerobic pool 3 has a built-in heating and stirring device 4, and the bottom of the anaerobic pool 3 discharges sludge; good Perforated aeration pipes and a flow control device are arranged in the oxygen tank 8, and the external air compressor 7 is blown and aerated, and the aeration rate is controlled by a rotameter, and mud is discharged from the bottom of the aerobic tank 8; the anaerobic tank 3 The temperature is 15-35°C, the stirring speed of the heating and stirring device 4 is 60-200r / min; the aeration rate is 0.5-10L / min; the dissolved oxygen DO of the aerobic tank 8 is 2.0-6.0mg / L, the temper...

Embodiment II

[0032] Embodiment II (1~3)

[0033] Similar to Example 1, the difference is that the type of wastewater is printing and dyeing wastewater. According to the influent organic load, the hydraulic retention time and circulation flow rate are determined, so that the domestic sewage is circulated through the dynamic membrane in the anaerobic tank and the aerobic tank respectively to complete the degradation of anaerobic and aerobic microorganisms, and the different degradation times are measured. COD, SS, DO, pH value, temperature and other indicators of the water body in the pool. The treatment effect of the waste water of embodiment II is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com