Intelligent injection molding machine and injection molding method thereof

An intelligent injection molding machine and injection molding machine technology, applied in the field of injection molding machines, can solve problems such as unstable production, adaptive adjustment, and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

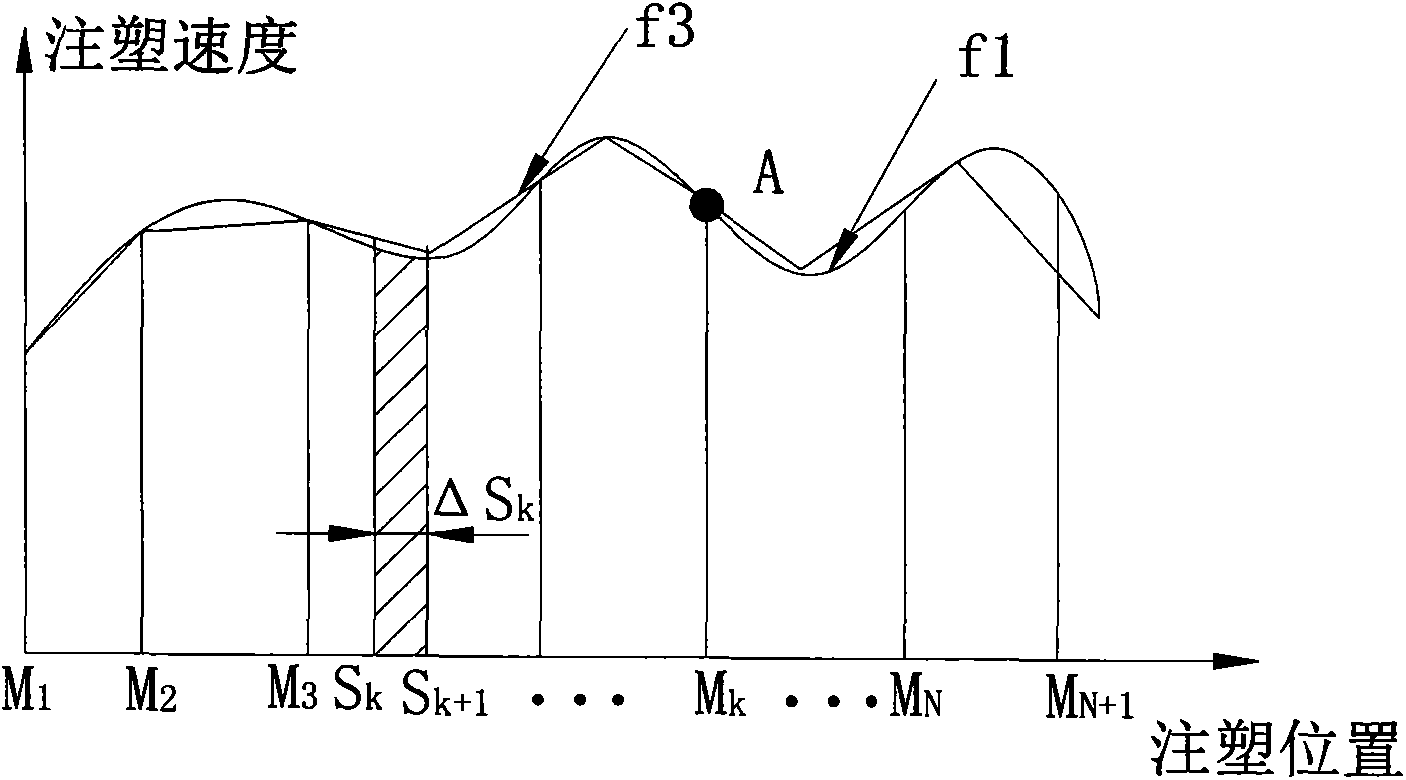

[0071] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

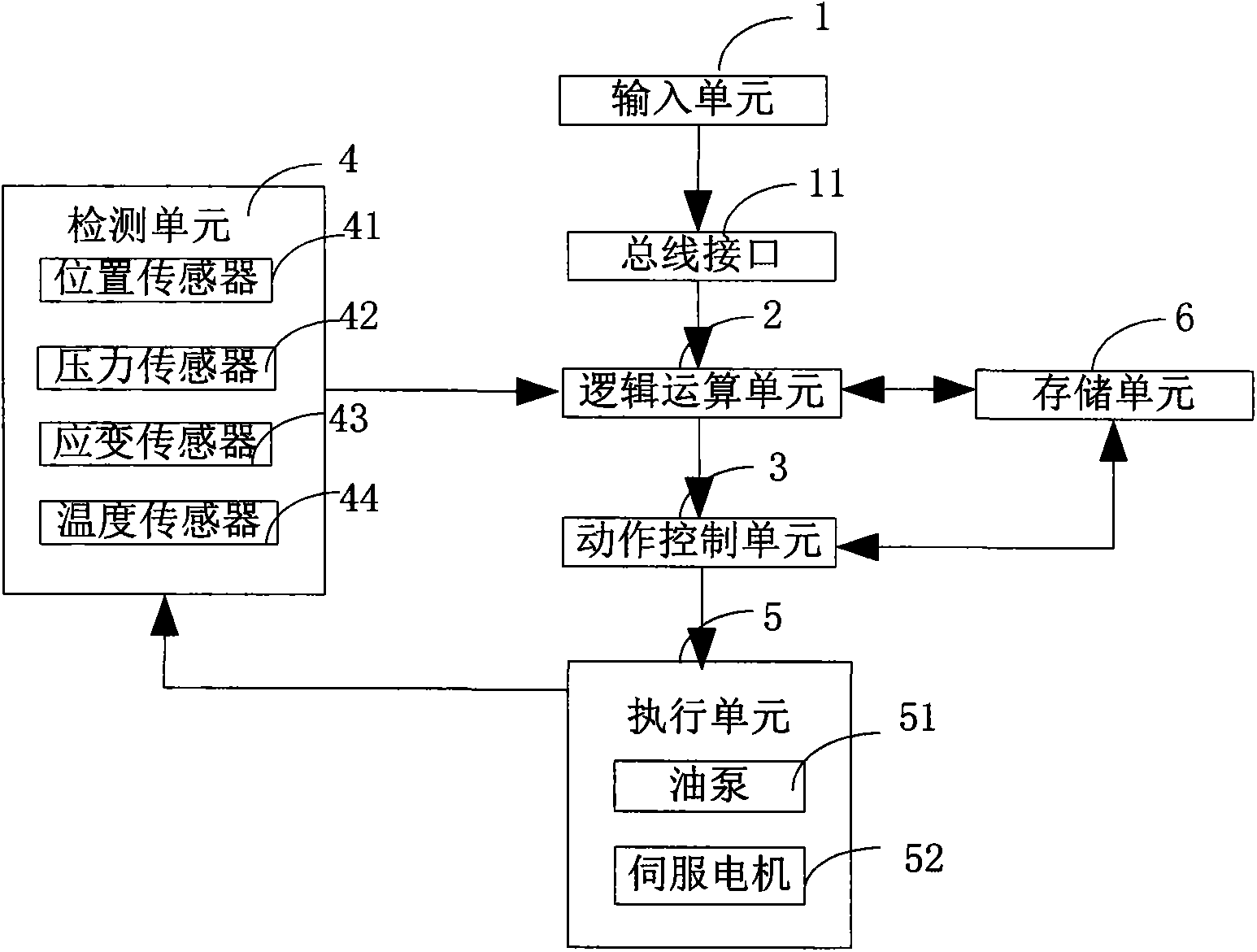

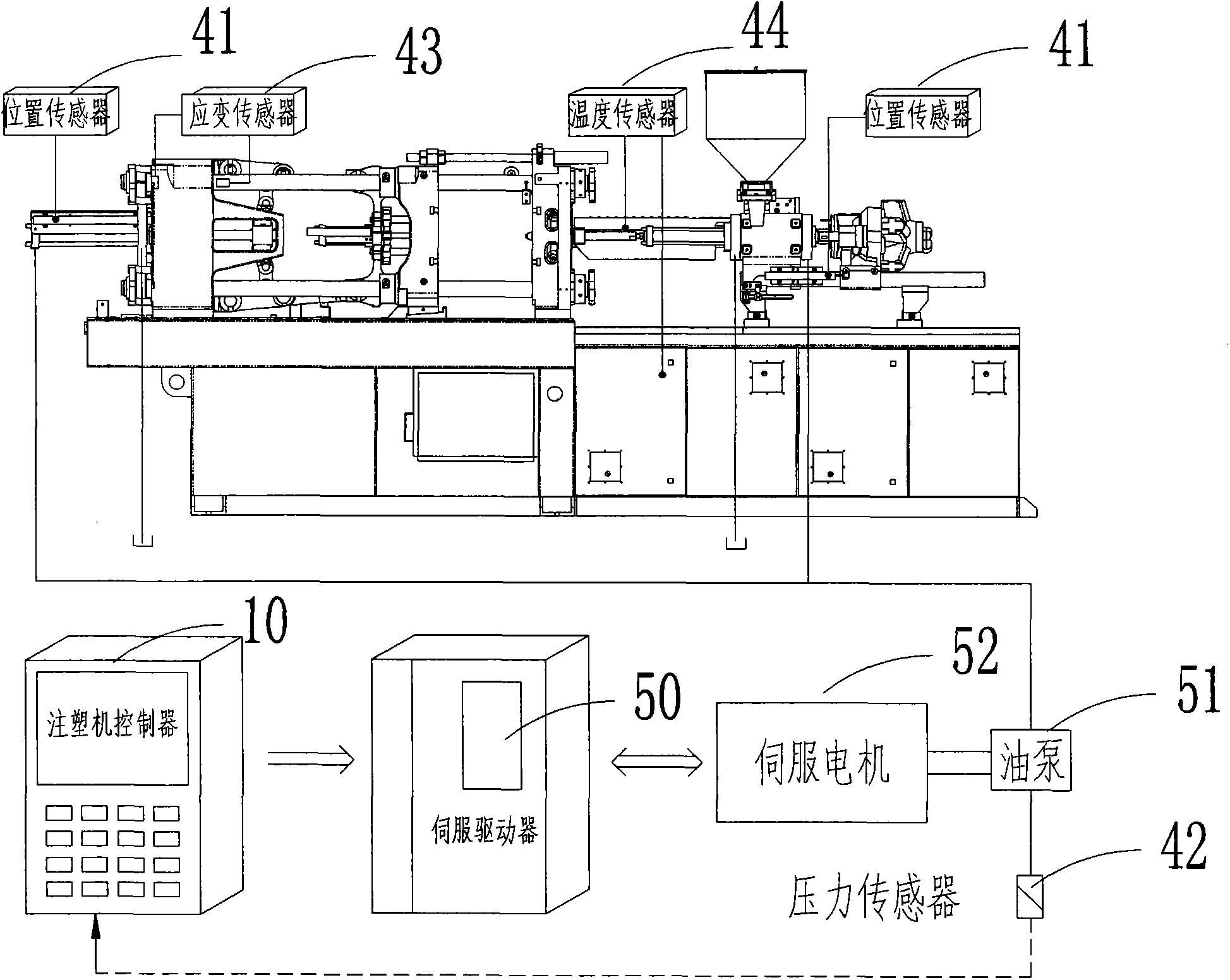

[0072] see figure 1 As shown, it is a functional block diagram of the control system of the intelligent injection molding machine of the present invention. In the present invention, the control system includes an input unit 1, a logical operation unit 2, a storage unit 6, an action control unit 3, an execution The unit 5 and a detection unit 4 perform data transfer between the input unit 1 and the logical operation unit 2 through the bus interface 11 .

[0073] The input unit 1 inputs the basic information of the processing technology that needs to be input: material, weight, density, mold opening stroke, and mold moving speed information into the control system through the man-machine interface; at the same time, for each type of injection molding machine, the The input unit 1 also inputs the basic param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com