High temperature ejector

An ejector and high-temperature technology, applied in the field of ejector, can solve the problems of calcium carbide furnace gas fluctuation, large fluctuation of furnace gas, long flue of calcium carbide furnace gas, etc., to ensure mechanical performance and stability, eliminate temperature difference stress, The effect of improving the work rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

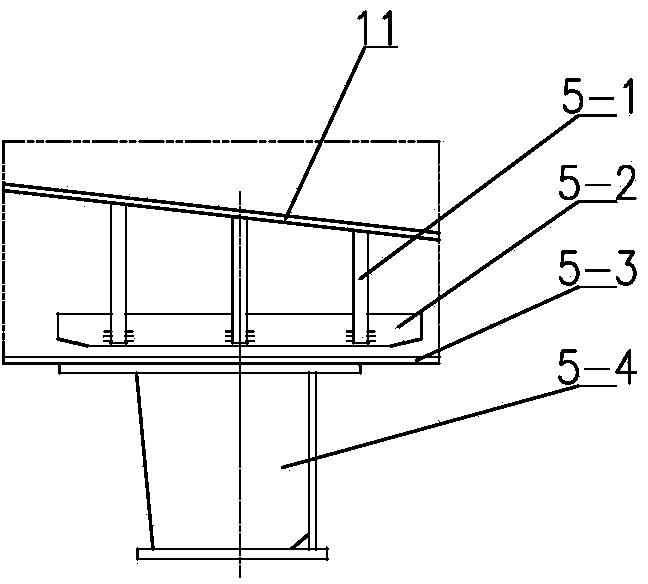

[0012] As shown in the accompanying drawings, a high-temperature ejector of the present invention includes an ejector housing 3 arranged in sequence along the horizontal direction, a first tapered pipe section 9, an equal-diameter pipe section 10, and a second tapered pipe section 11. The diameter of the rear end of the first tapered pipe section is smaller than the diameter of the front end, the diameter of the rear end of the second tapered pipe section is larger than the diameter of the front end, and a furnace gas suction port 1 is installed at the front end of the ejector shell. A furnace gas outlet 4 is installed at the rear end of the conical pipe section, and the power booster pipe 2 is inserted from the ejector housing 3 into the ejector housing 3. The outlet of the power booster pipe 2 is set at the ejector At the communication poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com