Device for improving smoke discharge capability of heat-accumulation-type stove kiln

A regenerative furnace and capacity technology, applied in the direction of furnaces, waste heat treatment, furnace components, etc., can solve the problem of increasing the amount of flue gas flowing through the regenerator, poor smoke exhaust capacity of regenerative kiln, insufficient smoke exhaust capacity, etc. problems, to achieve the effects of improving smoke exhaust capacity, ensuring furnace pressure, and improving recovery and utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

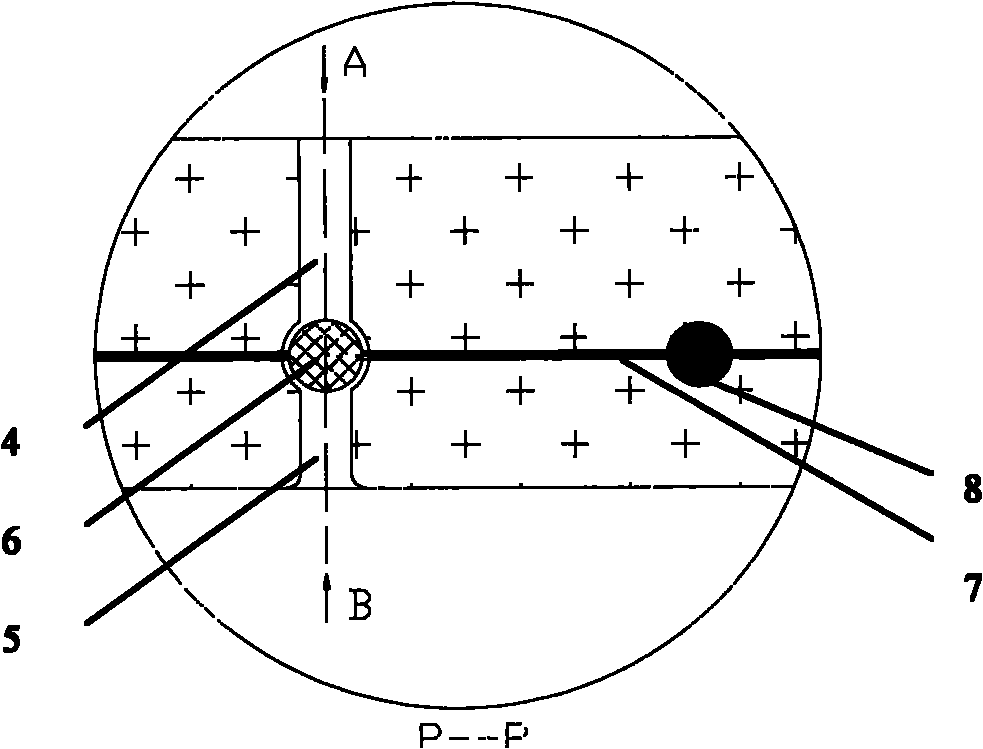

Embodiment 1

[0030] Taking the blast furnace gas double regenerative heating furnace as an example, the flow rate of the air nozzle is set to 1000Nm 3 / h, the air supply pressure is 5000Pa, and the induced air pressure is 5000Pa. In order to ensure that the air flow rate at the nozzle reaches 8Nm3 / s, the diameter of the nozzle is 210mm, and the number of auxiliary channels is set on the burner brick to 4, and the increased circulation area is 12.5% of the original smoke exhaust area, then the channels on the 2 parts of the burner brick The diameter is 19mm. According to the calculation of combustion theory, 3000KJ / Nm 3 The blast furnace gas is completely combusted, and when the excess air coefficient is 1.1, the amount of flue gas produced is 2.075 times the amount of air, which is about to produce 2075Nm3 / h of flue gas. According to the corresponding relationship between the amount of air and gas, the air channel needs to discharge 44% of the flue gas. Smoke volume. Under the conditi...

Embodiment 2

[0032] Taking the blast furnace gas double regenerative heating furnace as an example, the flow rate of the gas nozzle is set to 1250Nm 3 / h, the main pipe pressure is 5000Pa, and the induced wind pressure is 5000Pa. In order to ensure that the air flow rate at the nozzle reaches 8Nm3 / s, the diameter of the nozzle is 220mm, and the number of auxiliary channels is set on the burner brick to 4, and the increased circulation area is 12.5% of the original smoke exhaust area, then the channels on the 2 parts of the burner brick The diameter is 27mm. According to the calculation of combustion theory, 3000KJ / Nm 3 The blast furnace gas is completely combusted, and when the excess air coefficient is 1.1, the amount of flue gas produced is 2.075 times the amount of air, which is about to produce 2500Nm3 / h of flue gas. According to the corresponding relationship between the amount of air and gas, the gas channel needs to discharge 56% of the gas Smoke volume. Under the condition tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com