Recycling system of smoke gas energy for realizing high-temperature and low-oxygen combustion

A high-temperature low-oxygen combustion and flue gas technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of high energy consumption and low yield of industrial furnaces, etc., and achieve reduced oxidation burning loss, good air tightness, and reduced Effects of Pollutant Emissions

Inactive Publication Date: 2010-12-01

北京沃克能源科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a flue gas energy recycling system that realizes high-temperature low-oxygen combustion, uses the flue gas waste heat circulation system to continuously preheat the air at high temperature, and reduces the oxidizing atmosphere of combustion to greatly reduce the oxidation of steel parts Burning loss rate, solve the problems of high energy consumption and low yield of industrial furnaces

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

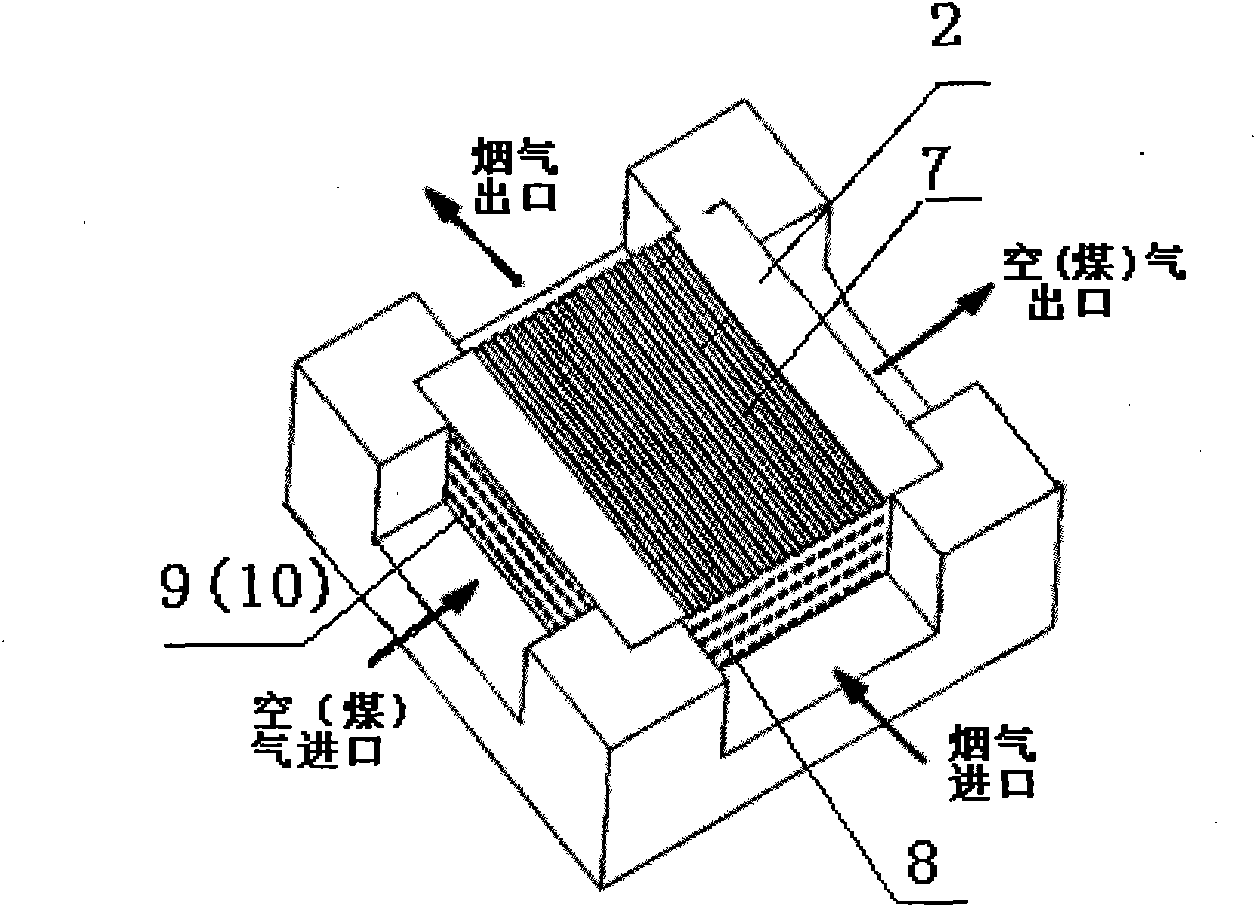

The invention relates to a recycling system of smoke gas energy for realizing high-temperature and low-oxygen combustion, belonging to the technical field of industrial furnaces. The system comprises a heating furnace, a continuous heat recovering apparatus, a chimney, a high-pressure blower, a coal gas compressor and a high-temperature and low-oxygen combustor; high-temperature smoke gas generated by the heating furnace firstly enters the continuous waste heat recovering apparatus deposited in the middle of a gas duct so that funnel temperature of the smoke gas is reduced to above dew point temperature via absorbing physical heat of the smoke gas, the smoke gas is discharged via the chimney; in the opposite direction of smoke gas flow, air and coal gas are pumped from the other end of the continuous heat recovering apparatus via the high-pressure positive blower and the coal gas compressor; the continuous residual heat recovering apparatus pre-heats the cold air and cold coal gas at 550 DEG C to 900 DEG C in contra-flow with the smoke gas. High-temperature air, high-temperature coal gas and partial smoke gas are organized to be combusted by the high-temperature and low-oxygen combustor, thereby realizing stable combustion in low-oxygen condition and reducing oxidation loss of iron works. The invention has the advantages of solving the problem of high energy consumption of industrial furnace, low yield and having obvious economic and social benefits.

Description

A flue gas energy recycling system that realizes high-temperature low-oxygen combustion technical field The invention belongs to the technical field of industrial furnaces, in particular to a flue gas energy recycling system for realizing high-temperature and low-oxygen combustion. The flue gas energy recycling system applies high-temperature air low-oxygen combustion technology and continuous preheating technology to achieve high-efficiency combustion and low pollutant emissions. technical background The production process of industrial furnaces has the characteristics of high energy consumption, high pollution and low yield. Engineers and technicians have been seeking various energy-saving and material-saving measures in terms of improving combustion equipment and recovering flue gas waste heat, so as to improve the fuel utilization rate of the furnace and reduce the oxidation and burning loss of steel parts under high-temperature furnace conditions. (1) Generally, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F27D17/00F23D14/22F23D14/66

CPCY02E20/34Y02P10/25Y02P80/15

Inventor 郑克明

Owner 北京沃克能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com