A regenerative combustion control system and its control method

A technology of a control system and a control method, which is applied in the control of combustion, furnace control devices, lighting and heating equipment, etc., can solve the problem of obvious unevenness of the exhaust gas temperature of the regenerator, large consumption of time, energy and financial resources, and large fluctuation of furnace pressure. and other problems, to achieve the effects of good exhaust gas temperature uniformity, shortened heating time, and stable furnace pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0040] The working principle of the present invention is as follows:

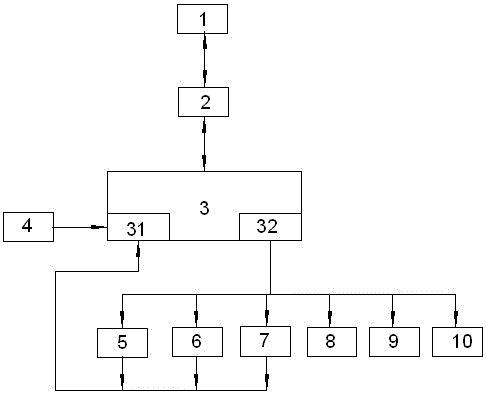

[0041] The structural diagram of the thermal storage control system described in the present invention is shown in figure 1. The system includes the upper industrial computer 1 with the configuration software installed connected to the lower PLC master station 2 through the industrial Ethernet network, and the lower PLC master station 2 and the lower PLC slave station 3 placed near the heating furnace are connected through the PROFIBUS field bus , the PLC master station 2 of the lower computer is responsible for controlling the operation of the program. Through the PROFIBUS field bus, the PLC slave station 3 of the lower computer placed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com