Honeycomb ceramic heat exchanger

A technology of honeycomb ceramics and heat exchangers, which is applied in the field of high-temperature and high-efficiency gas-gas honeycomb ceramic heat exchangers. Small size, convenient on-site construction, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

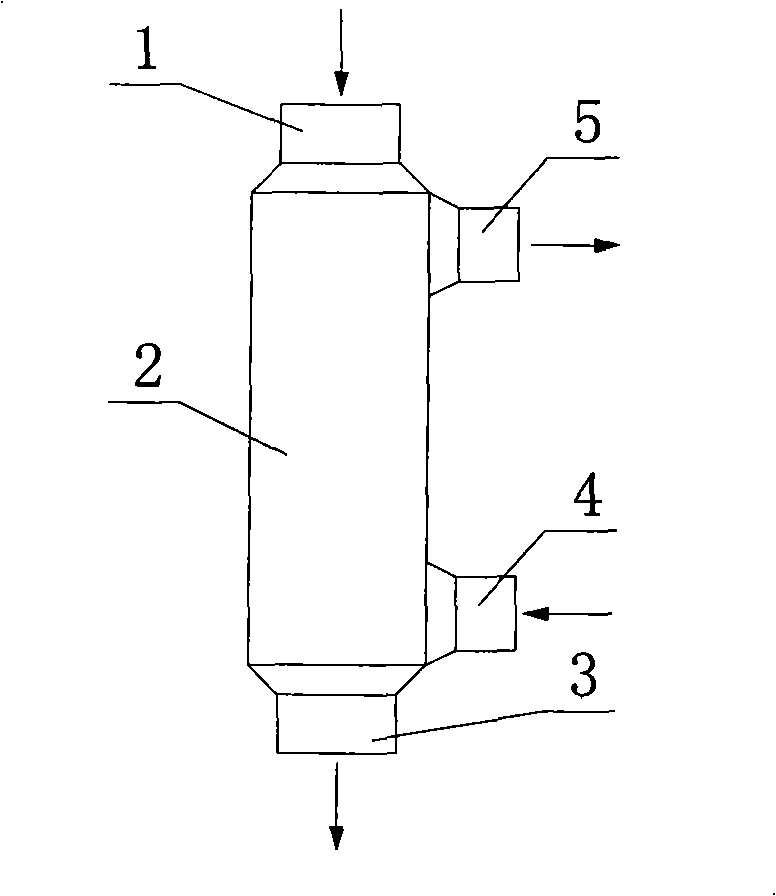

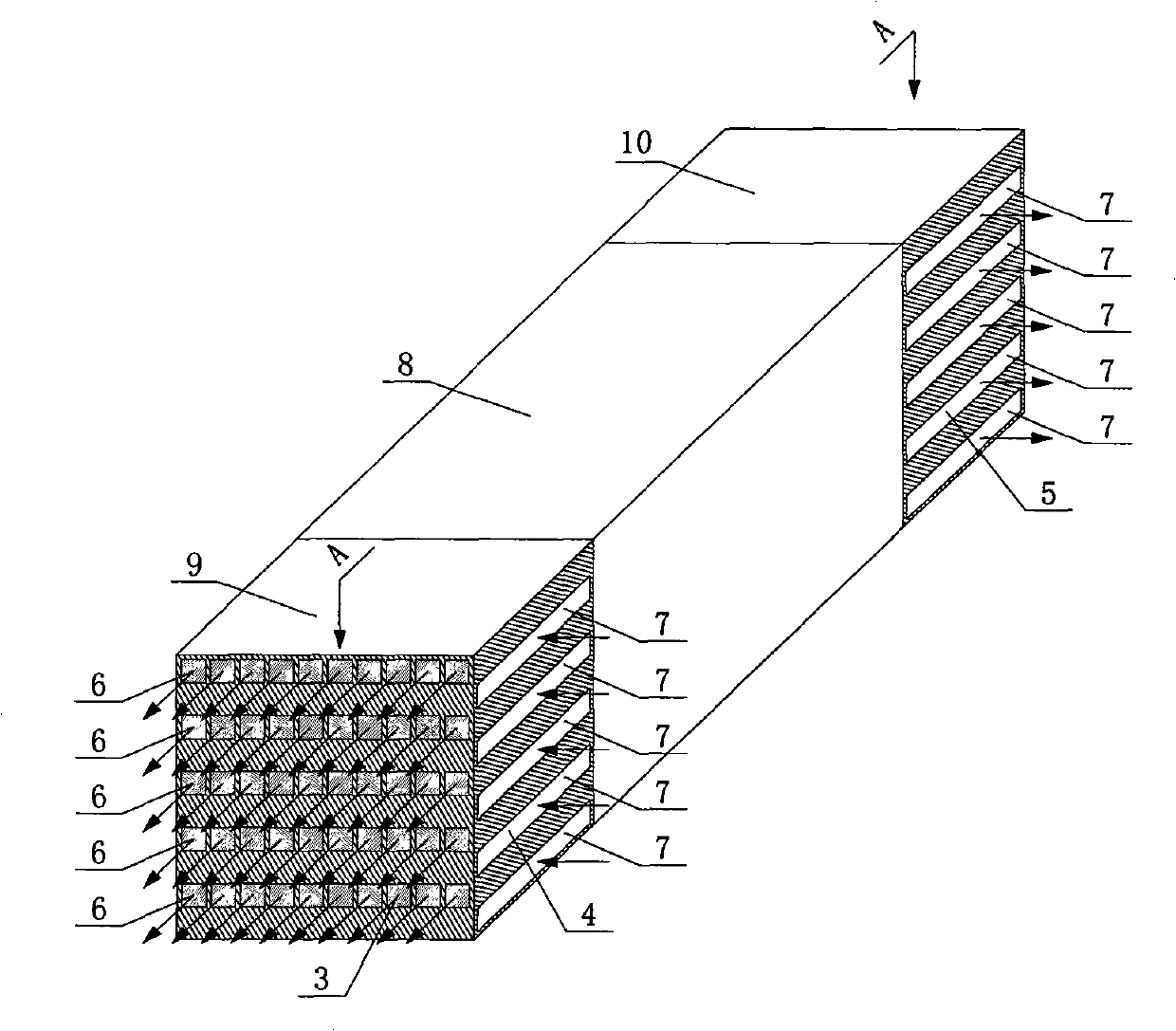

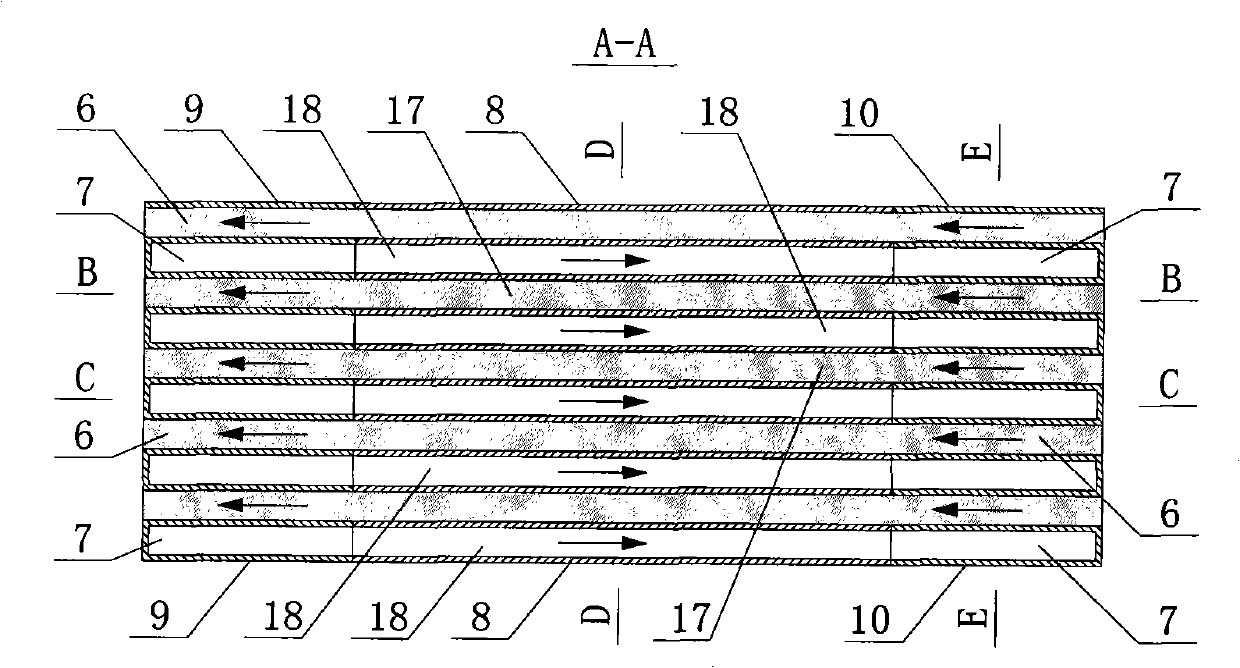

[0031] Honeycomb ceramic heat exchangers designed to heat only one gas (see Figure 12-13 ).

[0032] This heat exchanger is suitable for situations where it is not necessary to heat the fuel, but only the oxidant such as air or oxygen. The heat exchanger is mainly composed of flue gas inlet 1, flue gas outlet 3, air inlet 4, air outlet 5 and heat exchanger body 2; flue gas inlet 1 is installed at one end of heat exchanger body 2, and flue gas outlet 3 is installed At the other end of the heat exchanger main body 2; form a straight line connection; the air inlet 4 and the air outlet 5 are respectively installed at the two head basic units on the same side of the heat exchanger main body 2 to form a U-shaped connection (see Figure 12 ). Heat exchanger body 2 is the heart of the heat exchanger (see Figure 13 ), consisting of 4 main heat exchange body basic units 8, 2 A-type head basic units 9, 2 B-type head basic units 10 and 4 C-type head basic units 12. Among them, four ...

Embodiment 2

[0034] A honeycomb ceramic heat exchanger designed to heat two gases at the same time (one is air as the oxidant, and the other is blast furnace gas as fuel) (see Figure 14-15 ).

[0035] The heat exchanger is mainly composed of flue gas inlet 1, flue gas outlet 3, air inlet 13, air outlet 14, blast furnace gas inlet 15, blast furnace gas outlet 16 and heat exchanger main body 2. The main body 2 of the heat exchanger is the core of the heat exchanger, which consists of 9 main heat exchange body basic units 8, 3 A-type head basic units 9, 3 B-type head basic units 10 and 12 C-type heads The basic unit 12 is composed. Nine main heat exchange body basic units 8 are connected in parallel, and each head basic unit is connected in series with the main heat exchange body basic unit 8 according to the gas circulation process route. The main body of the heat exchanger 2 is divided into 3 layers, each layer includes 3 main heat exchange body basic units 8 and 6 required head basic un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com