Die-cast product rigidity evaluation method and die-cast product

A strength evaluation and product technology, applied in the direction of strength characteristics, using stable torsion to test the strength of materials, casting molds, etc., can solve problems such as fracture and strength drop, achieve accurate evaluation, and shorten the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

[0059] Hereinafter, a first embodiment of a method for evaluating the strength of a die cast product will be described with reference to the drawings.

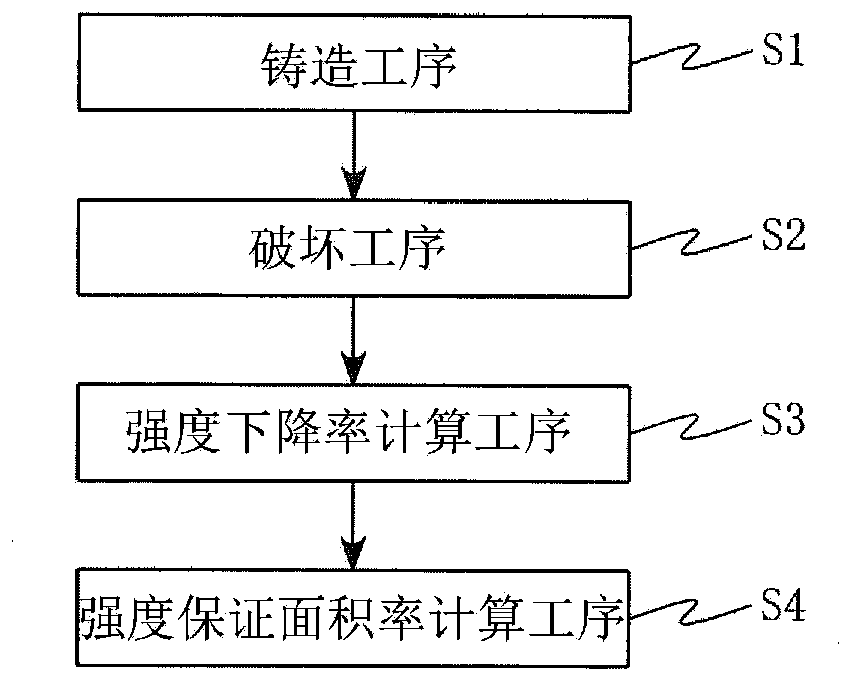

[0060] like figure 1 As shown, the present embodiment includes a casting step ( S1 ), a breaking step ( S2 ), a strength reduction rate calculation step ( S3 ), and a strength evaluation area ratio calculation step ( S4 ).

[0061]

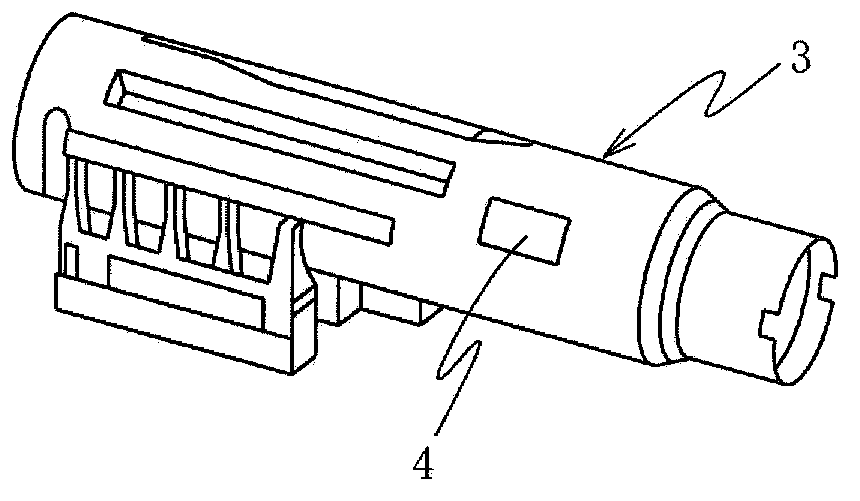

[0062] The casting process in this embodiment is a process of performing die casting using, for example, Al-Si-Cu-based aluminum alloy ADC12 of JIS H5302. The die-cast product obtained by this process is preferably figure 2 Steering column housing 3 of the shown vehicle handling device.

[0063]

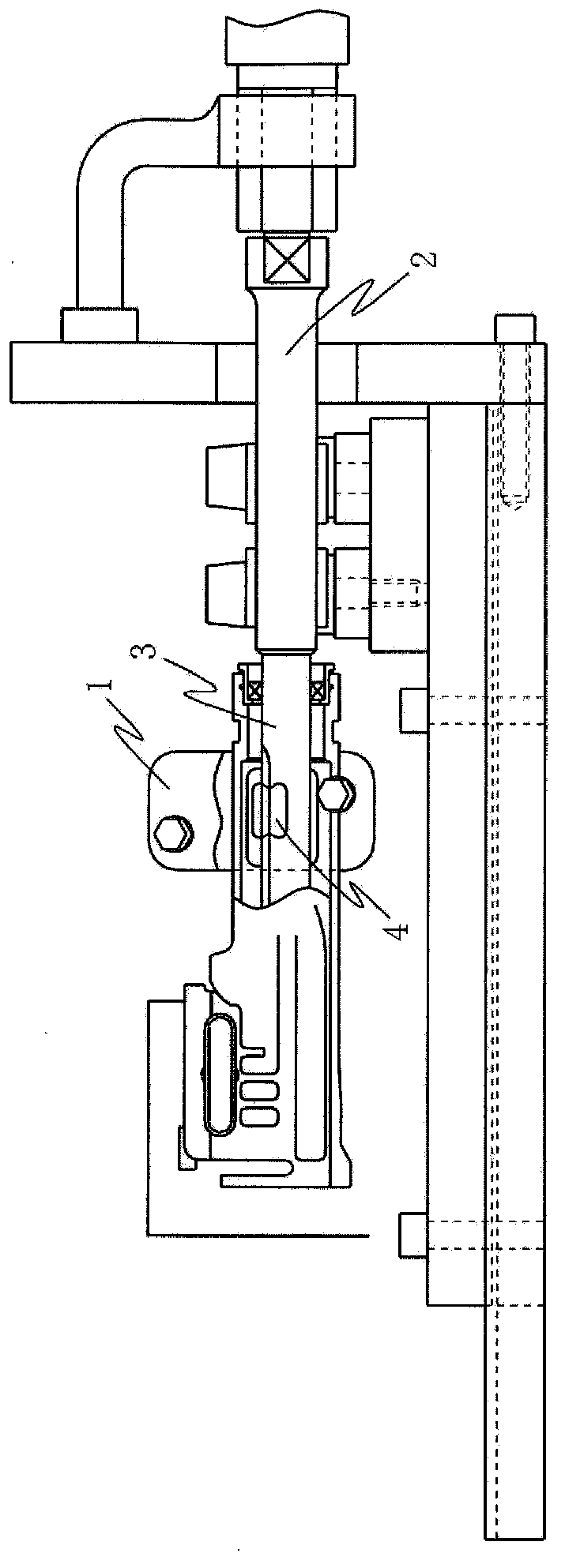

[0064] The breaking step in the present embodiment is a step of conducting a breaking test at the casting site of the die-cast product obtained by the casting step described above. The fracture test is preferably a torsion test.

[0065] The torsion test is specifically as image 3 As shown, th...

no. 2 Embodiment approach )

[0088] Next, a second embodiment of a method for evaluating the strength of a die cast product will be described with reference to the drawings.

[0089] Image 6 It is an explanatory diagram of the 6-axis movable ultrasonic flaw detector used in the strength evaluation method of the die-cast product of the present embodiment, Image 6 a is the overall diagram of the device, Image 6 b is a detailed diagram of the object to be tested and the rotary table, Image 6 c is an explanatory diagram of internal defect detection. Numeral 11 in the drawing is an aluminum die-cast product to be evaluated for strength in this embodiment, for example, a column housing of an electric power steering apparatus.

[0090]In the present embodiment, the aluminum die-cast product (column case) 11 is mounted above the turntable 12 , and the probe (probe) 13 is moved from above to below while the turntable 12 is rotated. The inner side of the casing) 11 is tested in a spiral shape. The die-cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com