Ethylene-vinyl alcohol copolymer resin composition and method for producing same

A technology of a resin composition and a manufacturing method, which is applied in the field of ethylene-vinyl alcohol copolymer resin compositions, can solve problems such as color deterioration of EVOH resin compositions, and achieve excellent appearance properties, yellowing inhibition, and excellent appearance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0127] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples.

[0128] In the following examples and comparative examples, the analysis and evaluation of the EVOH resin composition and the like were carried out according to the methods shown below.

[0129] (1) Determination of moisture content of water-containing EVOH particles

[0130] The moisture content of the hydrous EVOH pellets was measured using a halogen moisture content analyzer "HR73" manufactured by Mettler Toledo Co., Ltd. under conditions of a drying temperature of 180° C., a drying time of 20 minutes, and a sample weight of about 10 g. The water content of hydrous EVOH shown below is mass % based on the dry weight of EVOH.

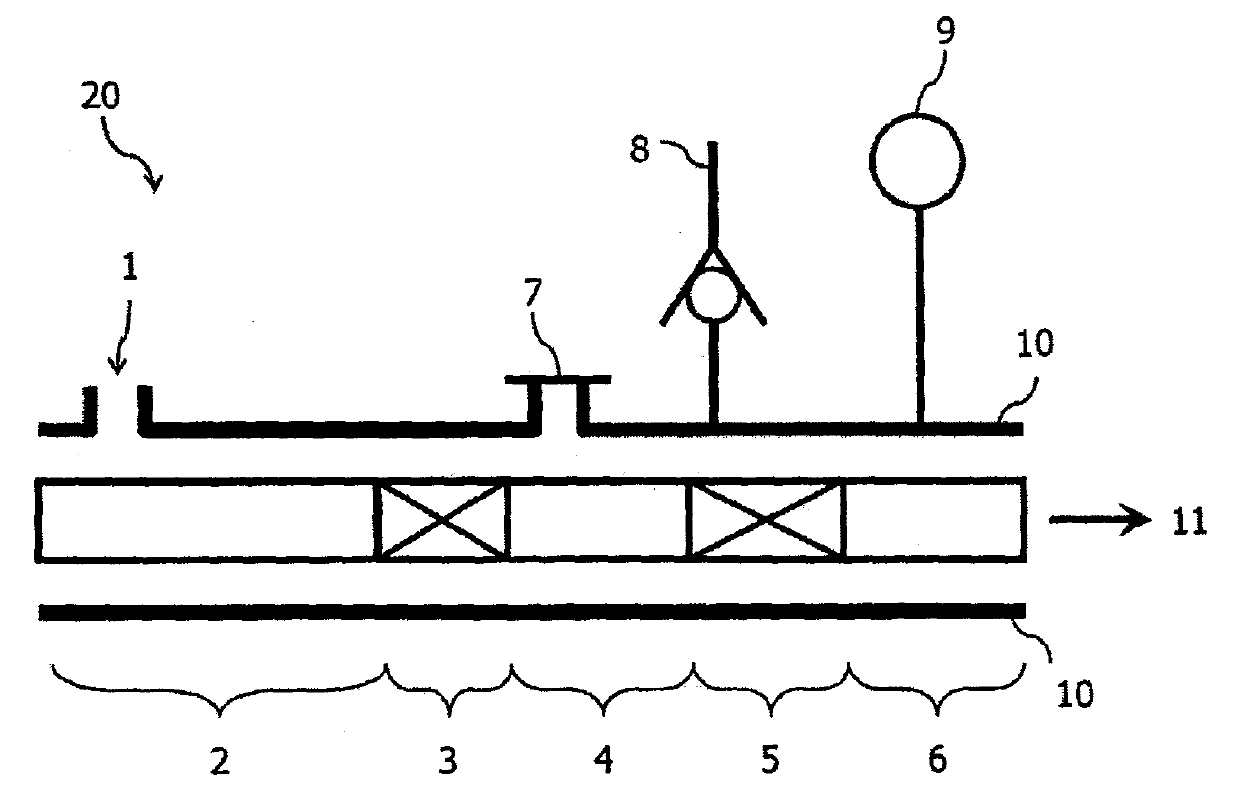

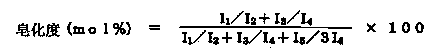

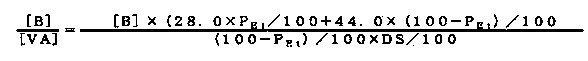

[0131] (2) Ethylene content and saponification degree of EVOH (A)

[0132] The dried EVOH particles were pulverized by freeze pulverization. The obtained pulverized EVOH was sieved with a sieve having a nominal size of 1 m...

Synthetic example 1

[0235] Synthesis of water-containing EVOH particles

[0236] (polymerization of ethylene-vinyl acetate copolymer)

[0237] Charge 85.3 kg of vinyl acetate and 21.6 kg of methanol into a 250 L pressurized reaction tank equipped with a stirrer, nitrogen inlet, ethylene inlet, initiator addition port, and delay (sequential addition) solution addition port, raise the temperature to 60 ° C, and then Nitrogen replacement in the system was carried out by nitrogen bubbling for 60 minutes. Next, ethylene was charged so that the pressure of the reaction tank became 3.7 MPa. As an initiator, 2,2'-azobis(4-methoxy-2,4-dimethylvaleronitrile) (AMV) was dissolved in methanol, and an initiator solution with a concentration of 1.9 g / L was prepared for Nitrogen substitution was performed by bubbling nitrogen gas. The internal temperature of the above-mentioned polymerization tank was adjusted to 60° C., and then 653 mL of the above-mentioned initiator solution was injected to initiate polym...

Synthetic example 2

[0246] Synthesis of water-containing EVOH particles

[0247] In Synthetic Example 1, the loading amounts of vinyl acetate and methanol during the polymerization of the ethylene-vinyl acetate copolymer were changed to 71.1kg and 4.28kg respectively, the pressure of the reaction tank was changed to 6.65MPa, and the initiator solution (AMV In addition, the injection amount at the start of polymerization was changed to 1305mL, the continuous addition amount of the initiator solution was changed to 2145mL / hr, and the inner temperature of the polymerization tank was changed to 55°C. A methanol solution of EVAc from which unreacted vinyl acetate monomer was removed was obtained by the same operation as in Synthesis Example 1. At this time, the polymerization rate was 35%.

[0248] Next, the amount of alkali solution added to 200.0 kg of EVAc in methanol (30 kg of EVAc in the solution) was changed to 49.8 L, and the amount of acetic acid added during neutralization was changed to 6....

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com