Manufacturing method for micro-nano graphs used for integrated optoelectronic device

A technology of optoelectronic device and manufacturing method, applied in the field of optoelectronics, to achieve the effects of high resolution, high yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

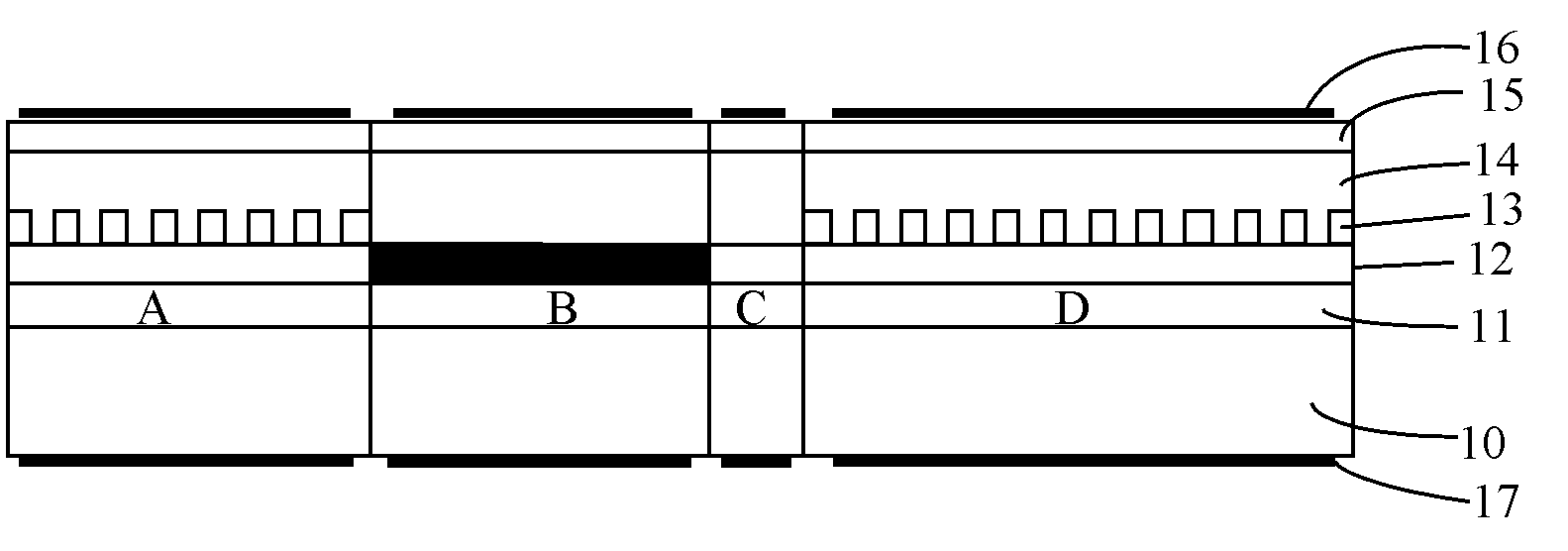

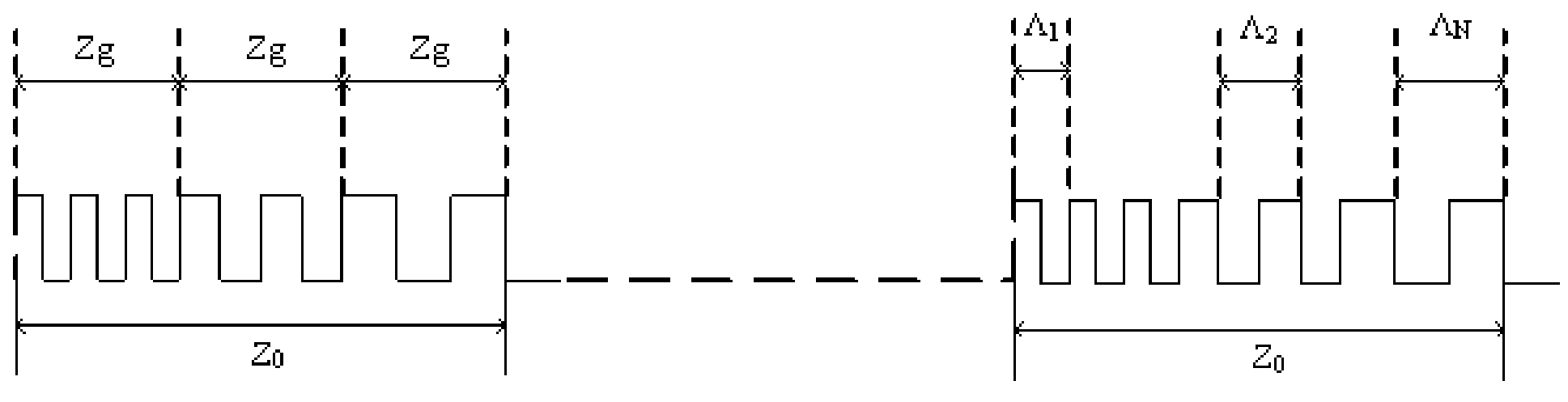

[0032] The invention adopts the nano-imprinting method combined with the nano-imprinting template fixing and aligning components to fix the nano-imprinting template and precisely align the nano-imprinting template and the graphic area of the embossing substrate.

[0033] The present invention comprises the steps:

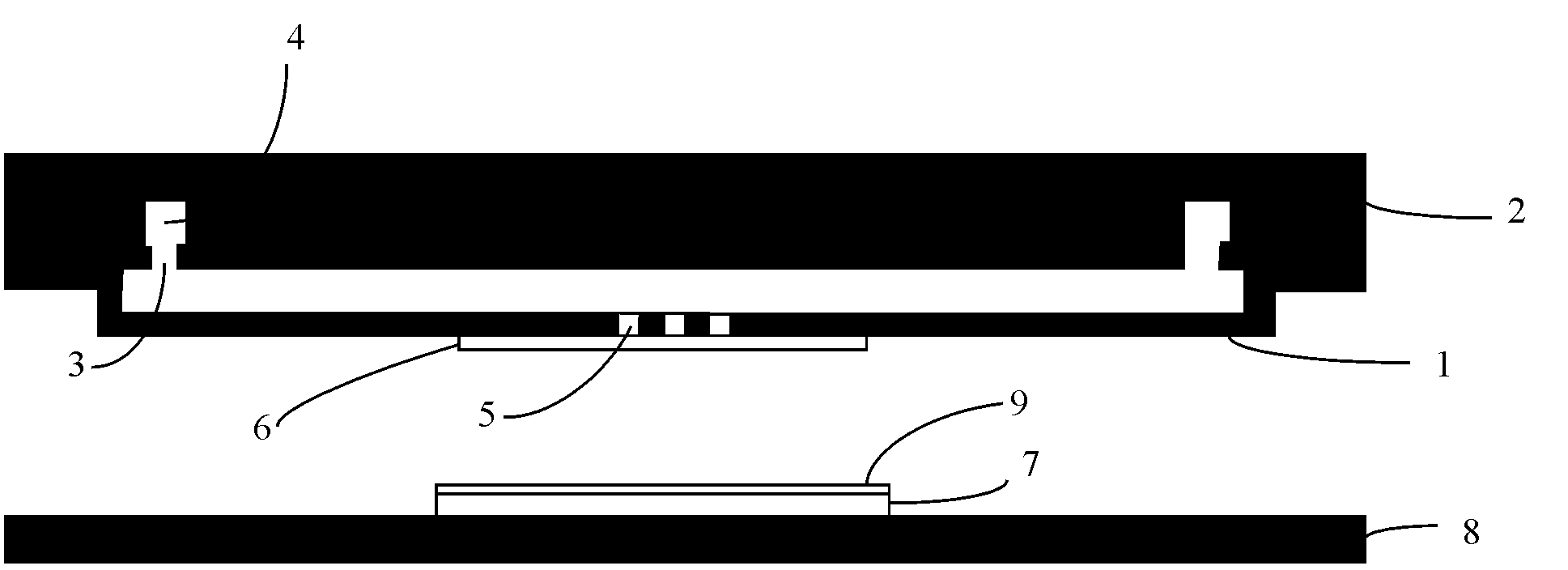

[0034] Step 1: Fix the stencil fixing and alignment component 1 with the stencil fixing jig 2 of the mask aligner, and the vacuum hole 3 on the upper part of the component 1 is located at the vacuum groove 4 of the stencil fixing jig 2 . After the vacuum is turned on, the vacuum suction passes through the vacuum groove 4 of the stencil fixing fixture 2, and is transmitted from the vacuum hole 3 in the component 1 to the vacuum hole 5 in the center of the lower surface of the component 1, and the stencil 6 is absorbed by the vacuum suction. At this position, the nanoimprint template 6 is fixed on the template fixing and alignment component 1 .

[0035] Step 2: Spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com