Motor substitution equipment for static force test of airplane wing

An alternative equipment, static test technology, applied in the field of alternative equipment, aircraft wing static strength test, can solve the problems of high risk, difficult to increase the test load point, high test cost, achieve large test load, reduce test risk, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

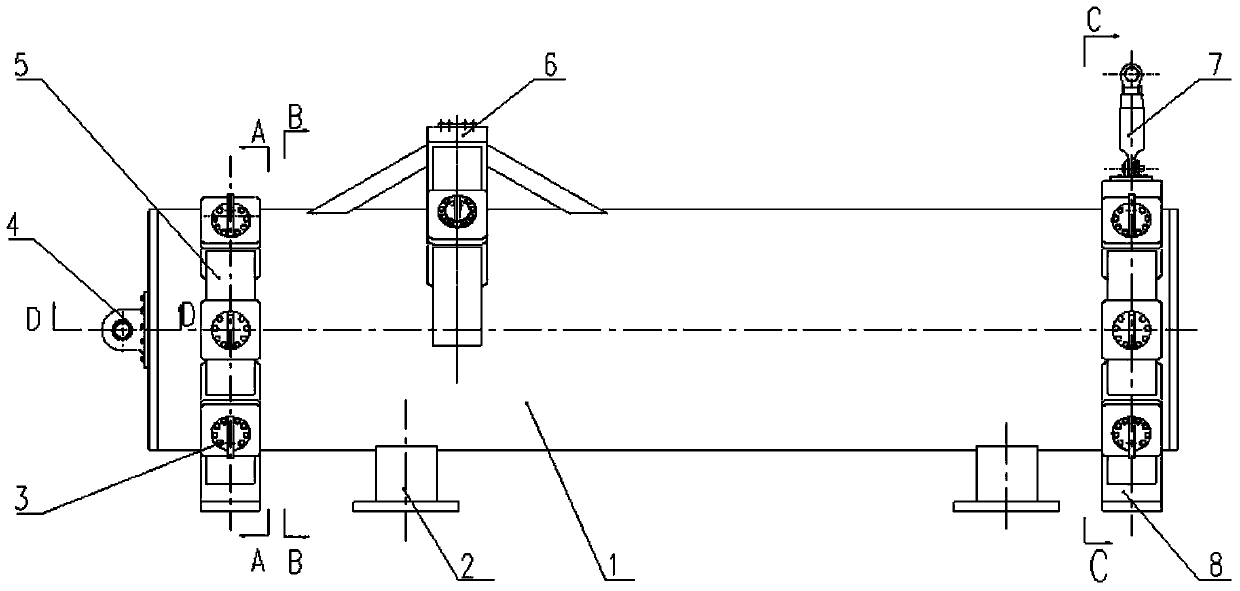

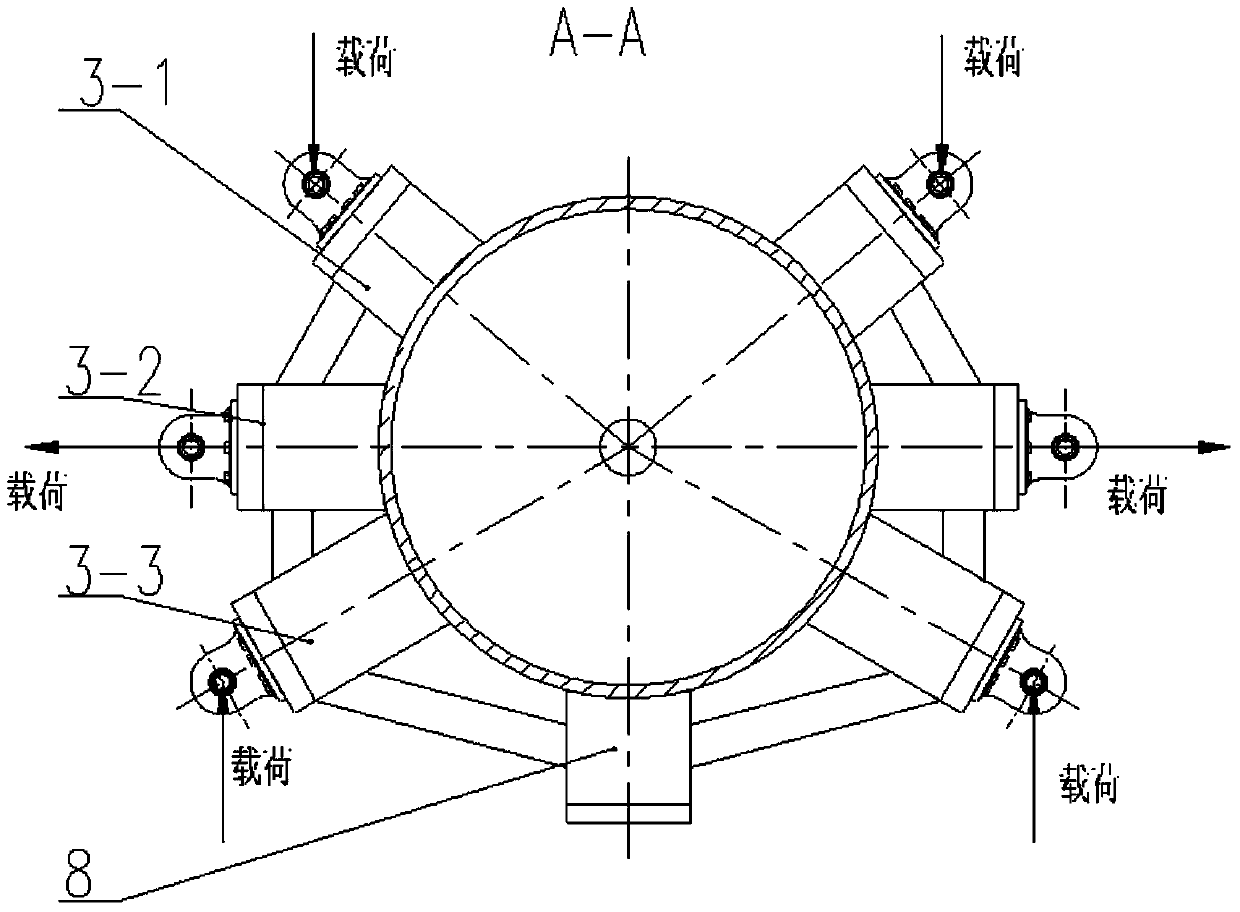

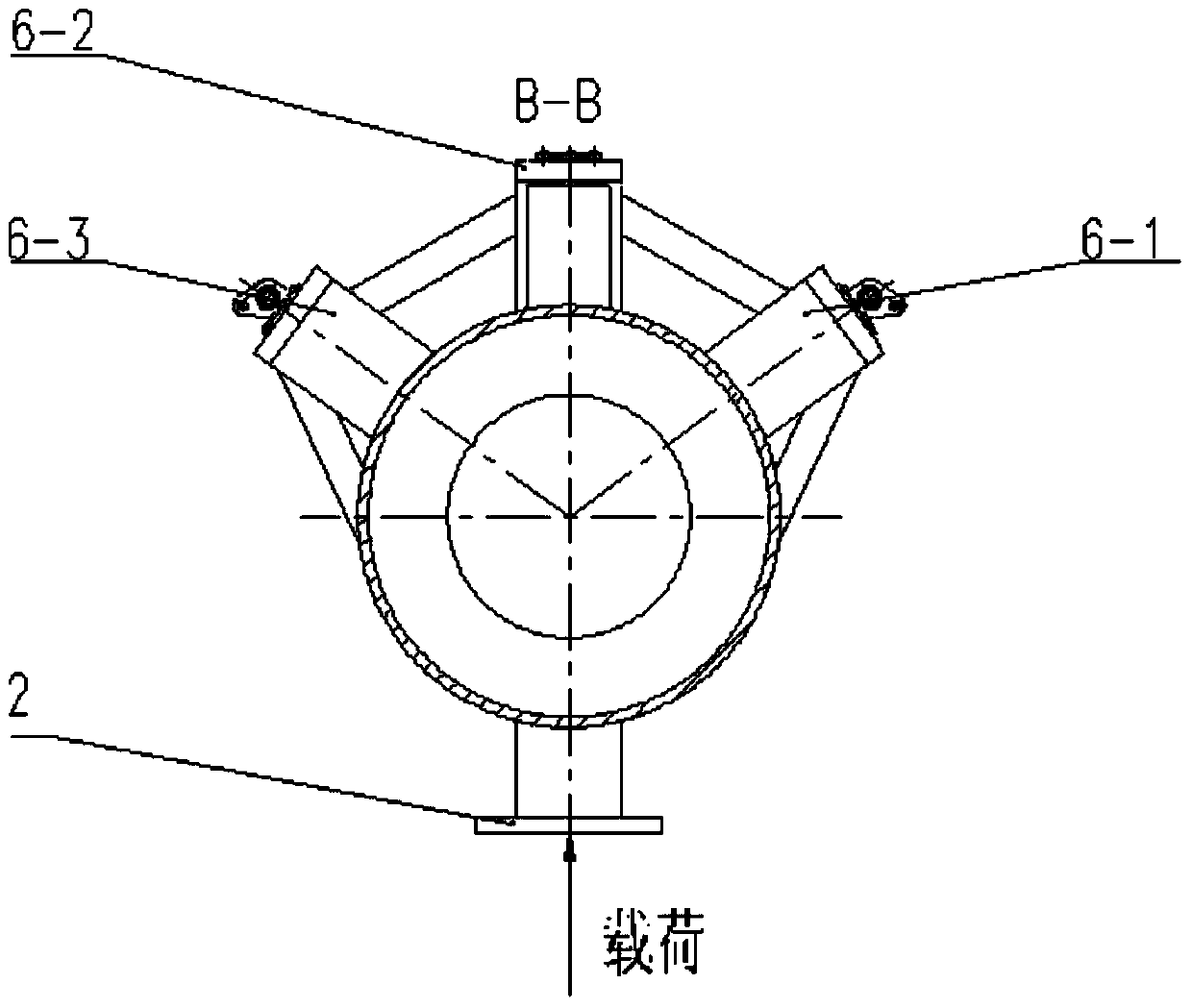

[0025] In this embodiment, the engine replacement equipment for the static test of the aircraft wing includes an engine simulation casing composed of a cylinder body 1, a front cover plate welded on the cylinder body, and a rear cover plate, and is fixedly arranged on the cylinder body radial direction. Two sets of transverse bearing joints 3 on both ends of the cylinder, axial bearing joints 4 fixedly arranged on the front cover plate along the axial direction of the cylinder, fixedly arranged on the upward loading platform 2 under the cylinder, and fixedly arranged on the top of the cylinder for For the suspension device 6 that suspends the replacement equipment under the wing of the aircraft, both the lateral bearing joint and the axial bearing joint are designed with a hinge connection structure with the load applying device.

[0026] The two sets of transverse load-bearing joints fixedly arranged on the two ends of the cylinder along the radial direction of the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com