High-performance structural combined floor slab

A combined floor and structural technology, applied in the direction of floor, structural elements, building components, etc., can solve the problems of labor and material environment, decrease of elastic modulus, influence of temperature, etc., to achieve good structural strength and stability, and save maintenance. Fees and Costs, Guaranteed Safety and Effectiveness of Service Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

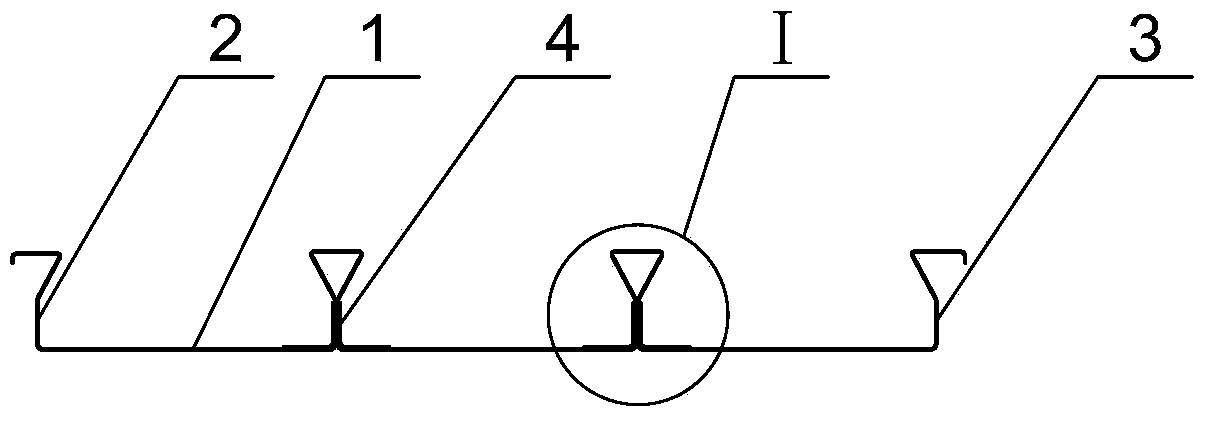

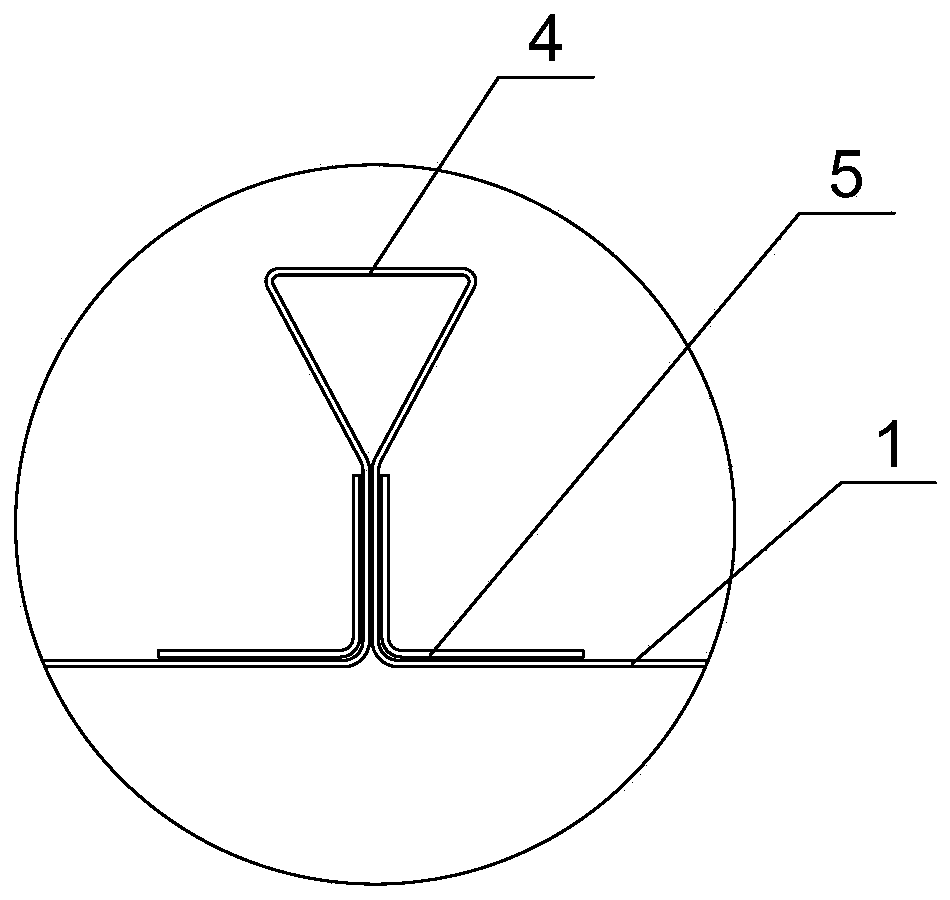

[0029] Such as figure 1 , figure 2As shown, the high-performance structural composite floor slab of this embodiment is a profiled plate that is integrally rolled and formed by steel plates through multiple passes, including a bottom plate 1, a first fastening portion 2 located at the left and right ends of the bottom plate 1, and a second Fastening part 3, two ribs 4 arranged at intervals in the middle of the bottom plate 1, the ribs 4 are closed ribs, the first fastening part 2 of the adjacent high-performance structural composite floor Fitted and fastened with the second fastening part 3, the overall shape of the first fastening part 2 and the second fastening part 3 after the fastening connection is consistent with the rib 4, so that It has the same function and structural characteristics as the rib 4, and it is less likely to fall off as a whole. The bottom plate 1, the first buckling part 2, the second buckling part 3, and the rib 4 are integrated Roll forming, the hig...

Embodiment 2

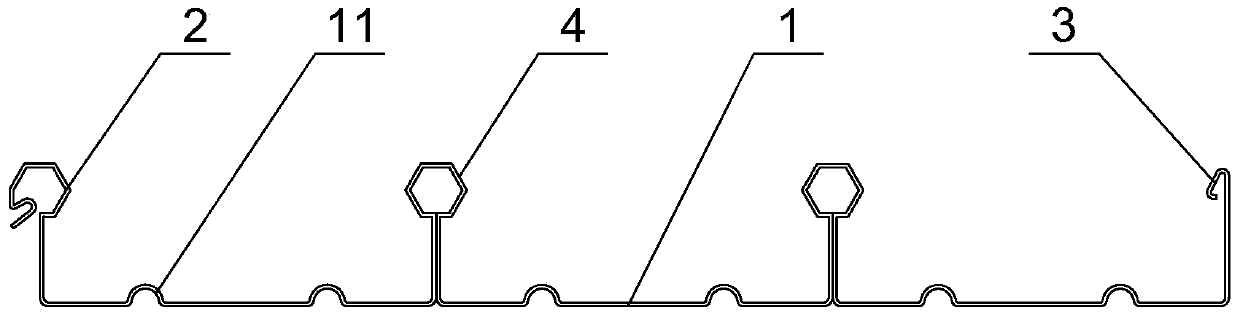

[0031] Such as image 3 , Figure 4 As shown, the difference between the high-performance structural composite floor of this embodiment and the first embodiment is that in this embodiment, the cross-section of the wedge-shaped part is a regular hexagon, and the adjacent high-performance structural composite floor After the first fastening part 2 and the second fastening part 3 are fastened and connected, the overall shape of the first fastening part 2 and the second fastening part 3 is also a regular hexagon, which can be further The contact area between the ribs 4 and the concrete increases, the bonding ability between the high-performance structural composite floor and concrete is enhanced, the high-performance structural composite floor is protected by concrete and is not easy to fall off, and the use of the high-performance structural composite floor is extended service life, and enhance the stability of the composite floor structure. Of course, the cross-section of the w...

Embodiment 3

[0034] Such as Figure 5 As shown, the difference between the high-performance structural composite floor of this embodiment and the second embodiment is that in this embodiment, the cross-section of the wedge-shaped part is circular, and all the adjacent high-performance structural composite floors After the first buckling part 2 and the second buckling part 3 are buckled and connected, the overall shape of the first buckling part 2 and the second buckling part 3 is also circular.

[0035] The rest of the features of this embodiment are the same as those of the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com