Preparation method for superfine fragrant soybean oil

A technology of soybean oil and strong aroma, which is applied in the production of edible oil/fat, fat oil/fat, and fat production, etc. It can solve the problem of lack of soybean oil, etc., and achieve the suppression of the formation of hydroperoxides, strong smell, and good transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

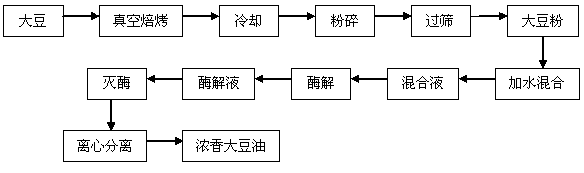

Image

Examples

preparation example Construction

[0014] A method for preparing aromatic soybean oil, the method comprising the following steps: (1) spreading soybeans on a tray, placing them in a vacuum oven for roasting, the roasting temperature is 150-200°C, and the roasting time is 10 -50min; (2) Cool the roasted soybeans to room temperature, then crush and sieve to obtain soybean powder. The mesh size of the sieve is 40-80 mesh. Mix the soybean powder with distilled water to form a mixed liquid. The solid-liquid ratio of the mixed liquid is 1:4-8; (3) Cellulase, plant hydrolysis complex polysaccharide enzyme Viscozyme L and alkaline protease Alcalase2.4L are added to the mixed liquid successively for enzymolysis, and enzymolysis is obtained after enzymolysis solution, the enzymolysis conditions of the cellulase Cellulase are 1.5% enzyme addition, enzymolysis temperature 45°C, enzymolysis pH 4, and enzymolysis time 2.5h, and the enzymolysis conditions of plant hydrolysis complex polysaccharide enzyme Viscozyme L are adding...

Embodiment 1

[0020] Spread the soybeans on a tray, place them in a vacuum oven, and bake them at 180°C for 30 minutes; cool the roasted soybeans to room temperature, then crush them and pass them through a 60-mesh sieve, and add distilled water according to a material-to-liquid ratio of 1:6 to form a mixture solution; at an enzymolysis temperature of 45°C and an enzymolysis pH of 4, add 1.5% Cellulase for enzymolysis for 2.5 hours, then at an enzymolysis temperature of 45°C and an enzymolysis pH of 4.6, add 1.5% The plant hydrolysis compound polysaccharide enzyme Viscozyme L was used for enzymolysis for 2 hours, and finally at the enzymolysis temperature of 55°C and the enzymolysis pH of 9, 2% alkaline protease Alcalase2.4L was added for enzymolysis for 2 hours, and the enzymolysis was obtained after enzymolysis solution; the enzymolysis solution was heated in a boiling water bath to inactivate the enzyme for 10 minutes, and then centrifuged at a temperature of 4°C and a rotation speed of 1...

Embodiment 2

[0022] Spread the soybeans on a tray, put them in a vacuum oven, and roast them at 150°C for 40 minutes; cool the roasted soybeans to room temperature, then crush them and pass through a 50-mesh sieve, and add distilled water according to a ratio of 1:6 to form a mixture. solution; at an enzymolysis temperature of 45°C and an enzymolysis pH of 4, add 1.5% Cellulase for enzymolysis for 2.5 hours, then at an enzymolysis temperature of 45°C and an enzymolysis pH of 4.6, add 1.5% The plant hydrolysis compound polysaccharide enzyme Viscozyme L was used for enzymolysis for 2 hours, and finally at the enzymolysis temperature of 55°C and the enzymolysis pH of 9, 2% alkaline protease Alcalase2.4L was added for enzymolysis for 2 hours, and the enzymolysis was obtained after enzymolysis solution; the enzymolysis solution was heated in a boiling water bath to inactivate the enzyme for 10 minutes, and then centrifuged at a temperature of 4°C and a rotation speed of 10,000 rpm for 15 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com