Hydrogenation method for producing lubricant basic oil with low pour point and high viscosity index

A lubricating oil base oil, high viscosity technology, applied in lubricating composition, hydrotreating process, petroleum industry, etc., can solve the problems of high raw material requirements and high wax content of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

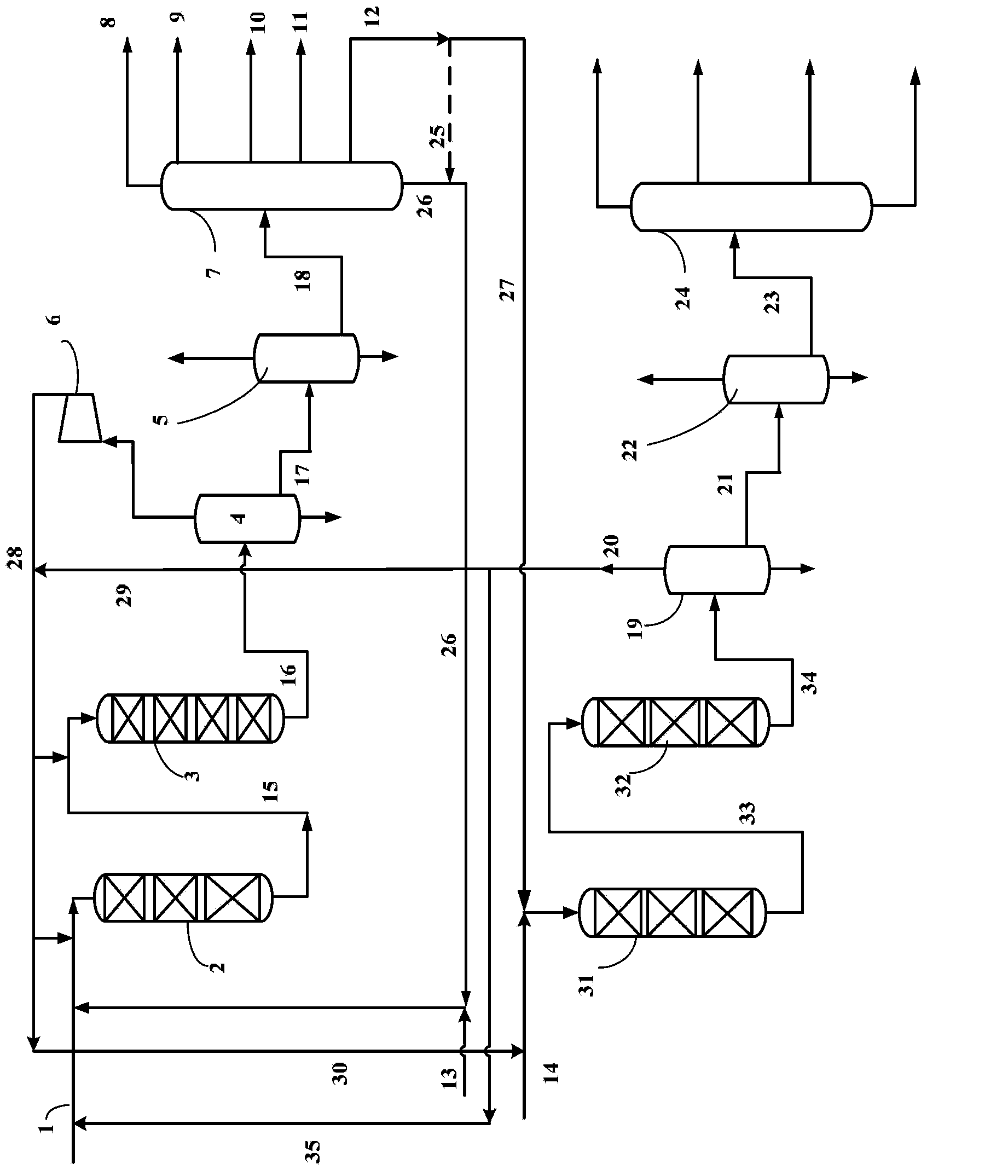

[0084] The feed oil A is mixed with hydrogen and passes through the first hydrogenation reaction zone and the second hydrogenation reaction zone in sequence, the first hydrogenation reaction zone is filled with a hydrofinishing catalyst, and the second hydrogenation reaction zone is filled with a hydrocracking catalyst A. At a hydrogen partial pressure of 14.0MPa, the reaction temperature in the first hydrogenation reaction zone is 382°C, and the volume space velocity is 1.1h -1 , the reaction temperature in the second hydrogenation reaction zone is 390°C, and the volume space velocity is 1.4h -1 The reaction is carried out under certain conditions, and the reaction effluent in the second hydrogenation reaction zone is separated and fractionated to obtain hydrogen-rich gas I, naphtha fraction, kerosene fraction, diesel fraction, tail oil fraction and heavy tail oil fraction, and the obtained> The 510°C heavy tail oil fraction is all recycled back to the first hydrogenation rea...

Embodiment 2

[0087] The feed oil A is mixed with hydrogen and passes through the first hydrogenation reaction zone and the second hydrogenation reaction zone in sequence, the first hydrogenation reaction zone is filled with a hydrofinishing catalyst, and the second hydrogenation reaction zone is filled with a hydrocracking catalyst B. At a hydrogen partial pressure of 15.0MPa, the reaction temperature of the first hydrogenation reaction zone is 380°C, and the volume space velocity is 1.2h -1 , the reaction temperature in the second hydrogenation reaction zone is 392°C, and the volume space velocity is 1.5h -1 The reaction is carried out under certain conditions, and the reaction effluent in the second hydrogenation reaction zone is separated and fractionated to obtain hydrogen-rich gas I, naphtha fraction, kerosene fraction, diesel fraction, tail oil fraction and heavy tail oil fraction, and the obtained> The heavy tail oil fraction at 530°C is all recycled back to the first hydrogenation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com