Preparation method of modified unsaturated polyester resin coating

A polyester resin, unsaturated technology, used in polyester coatings, polyurea/polyurethane coatings, coatings, etc., to achieve high activity, good overall performance, and good filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

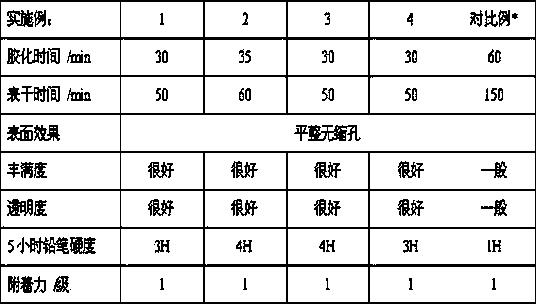

Examples

Embodiment 1

[0022] The aggregation steps are as follows:

[0023] (1) Synthesis of isocyanate prepolymer:

[0024] Add 1.01 mole of toluene diisocyanate dropwise to 1.00 mole of commercially available polyester diol, dibutyltin dilauric acid 0.01% mole, stir and mix at a slow speed at 50°C for further use.

[0025] (2) Preparation of polyurethane with epoxy resin at the end:

[0026] Add 1.01 mole of glycidyl ether epoxy resin dropwise to 1 mole of isocyanate prepolymer synthesized in step (1), add 0.05% mole of dibutyltin dilaurate catalyst, polymerize at 70°C, and synthesize the terminal group as epoxy Resin polyurethane, cool to room temperature.

[0027] (3) Preparation of polyurethane / epoxy resin modified unsaturated polyester resin coating:

[0028] Add 10 parts of polyurethane whose end is epoxy resin to 100 parts of commercially available common ortho-phthalic unsaturated polyester resin, and add 10 parts of 10% styrene diluent. Finally, add 0.5% triethylenediamine catalyst, 2...

Embodiment 2

[0031] The aggregation steps are as follows:

[0032] (1) Synthesis of isocyanate prepolymer:

[0033] Add 1.10 mol of diphenylmethane diisocyanate dropwise to 1.00 mol of commercially available polyether diol, 0.5% mol of dibutyltin dilauric acid catalyst, stir and mix at a slow speed at 50°C for further use.

[0034] (2) Preparation of polyurethane with epoxy resin at the end:

[0035] Add 1.10 moles of glycidyl ester epoxy resin dropwise to 1 mole of isocyanate prepolymer synthesized in step (1), add 0.5% mole of dibutyltin dilaurate catalyst, polymerize at 70°C, and synthesize the terminal group as epoxy Resin polyurethane, cool to room temperature.

[0036] (3) Preparation of polyurethane / epoxy resin modified unsaturated polyester resin coating:

[0037] Add 100 parts of polyurethane with epoxy resin terminal to 10 parts of commercially available common isophthalic unsaturated polyester resin and mix, and add 60 parts of 50% styrene butyl acetate diluent. Finally, add...

Embodiment 3

[0040] The aggregation steps are as follows:

[0041] (1) Synthesis of isocyanate prepolymer:

[0042] Add 1.05 moles of diphenylmethane diisocyanate dropwise to 1.00 moles of commercially available polyether diol, 0.5 moles of bis(dodecylsulfide) dibutyltin catalyst, stir and mix at a slow speed at 50°C until ready for use.

[0043] (2) Preparation of polyurethane with epoxy resin at the end:

[0044] Add 1.06 mol of glycidylamine epoxy resin dropwise to 1 mol of isocyanate prepolymer synthesized in step (1), add 0.1% mol of dibutyltin dilaurate catalyst, polymerize at 70°C, and synthesize the terminal group as epoxy Resin polyurethane, cool to room temperature.

[0045] (3) Preparation of polyurethane / epoxy resin modified unsaturated polyester resin coating:

[0046] Add 40 parts of polyurethane whose end is epoxy resin to 60 parts of commercially available common ortho-phthalic unsaturated polyester resin and mix, add 50 parts of acetone diluent with 20% styrene. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com