Constant viscosity natural rubber and preparation method thereof

A natural rubber and rubber technology, applied in the field of constant viscosity natural rubber and its preparation, can solve the problems of unstable quality of natural rubber, reduce Mooney viscosity, increase energy consumption, etc., and achieve good market promotion value, stable Mooney viscosity, The effect of reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

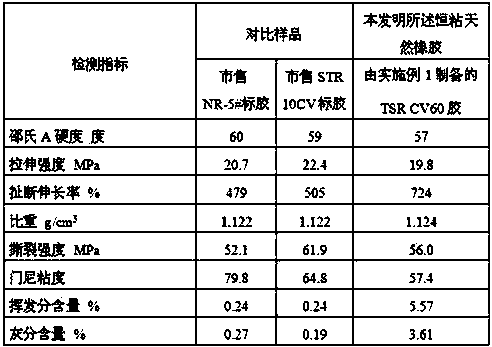

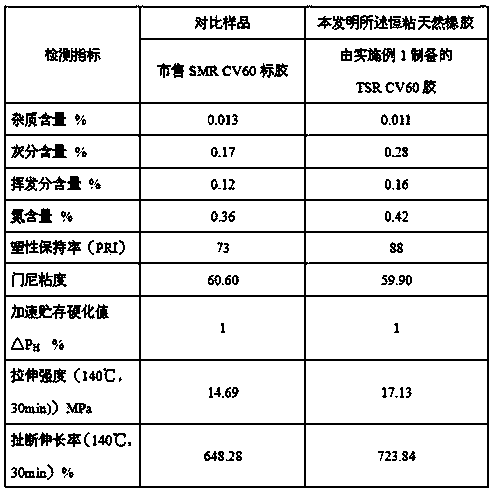

Examples

preparation example Construction

[0018] The preparation method of the constant-viscosity natural rubber of the present invention comprises purification, constant-viscosity treatment, solidification and aging, dehydration and impurity removal and drying processes, specifically comprising:

[0019] A. Purification: Make the fresh latex pass through the purifier to remove impurities;

[0020] B. Constant viscosity treatment: add ≥2.5% hydroxylamine constant viscosity agent solution and ≥8.0% hydrazine hydrate solution to the fresh latex after impurity removal, and mix and stir for no less than 20 minutes;

[0021] C. Coagulation and aging: using the acid coagulation method, the diluted latex and coagulation acid are mixed and flowed down the tank according to the volume ratio of 576~626:1, until the latex is solidified, shrinkage and dehydration;

[0022] D. Dehydration and impurity removal: The latex clot is thinned by a thinner and dehydrated. After the thin film is floated and washed, it is creped by a crepe ...

Embodiment 1

[0044] ——Preparation of permanent sticky natural rubber

[0045] A, purify: make fresh latex successively be 40 order and 60 order secondary sieves through aperture respectively, remove impurities such as silt, measure the dry glue content of fresh latex to be 35%.

[0046] B. Constant viscosity treatment: add 5% hydroxylamine constant viscosity agent solution and 10% hydrazine hydrate solution to the fresh latex after impurity removal, and mix and stir for 25 minutes.

[0047] C. Coagulation and aging: use acid coagulation method to dilute the treated latex with water to a concentration of 24%, and then flow it into the tank with formic acid at a volume ratio of 600:1 until the latex is solidified, shrinking and dehydrating, and the coagulation needs to control the latex The pH value is 4.3~4.6.

[0048] D. Dehydration and impurity removal: make the latex clot thinner and dehydrated, then soak the thin film in clean water, rinse for 3 minutes, then pass the thin film through...

Embodiment 2

[0051] ——Preparation of permanent sticky natural rubber

[0052] A, purify: make fresh latex successively pass through aperture and be respectively 40 order and 60 order secondary sieves, remove impurities such as silt, measure the dry glue content of fresh latex to be 40%.

[0053] B. Constant viscosity treatment: add 7% hydroxylamine constant viscosity agent solution and 12% hydrazine hydrate solution to the fresh latex after impurity removal, and mix and stir for 30 minutes.

[0054] C. Coagulation and curing: use acid coagulation method, dilute the treated latex with water to a concentration of 23%, and then flow it into the tank with acetic acid at a volume ratio of 576:1 until the latex is solidified, shrinking and dehydrating, and the coagulation needs to control the latex The pH value is 4.3~4.6.

[0055] D. Dehydration and impurity removal: make the latex clot thinner and dehydrated, then soak the thin film in clean water, rinse for 3 minutes, then pass the thin film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com