Humic acid type water-retaining slow-release controlled-release organic fertilizer prepared from wastes of sugar mills and alcohol plants

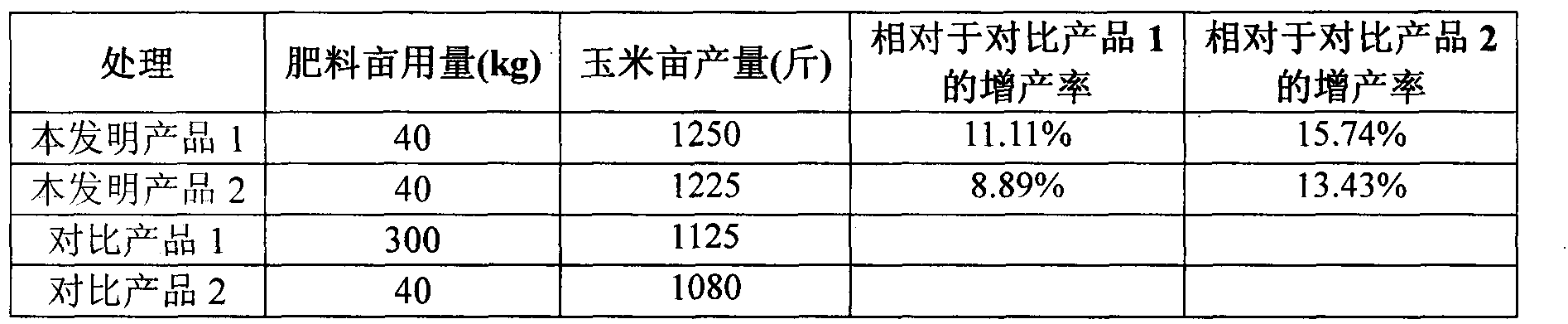

A technology of organic fertilizer and humic acid, which is applied in the field of fertilizer, can solve the problems of corn rooting and yield increase that have not been reported, and achieve the effects of enhancing lodging resistance, increasing root-to-shoot ratio, and increasing crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 The preparation of product 1 of the present invention

[0042] Take 1200kg of alcohol waste liquid from the sugar cane sugar factory, let it stand for clarification, and obtain the supernatant, then heat the supernatant to 75°C for evaporation and concentration to obtain 200kg of the concentrate, add nitric acid to the concentrate until the pH of the concentrate is 3. Stand at room temperature and activate for 18 hours, then add ammonia water to adjust the pH to 7 to obtain active humic acid liquid, dry the active humic acid liquid, pulverize, and sieve to obtain active humic acid, about 120kg for later use.

[0043] 30kg of polyacrylamide (purchased from Renqiu Zhenghao Chemical Products Co., Ltd.) and 300kg of rapeseed cake were weighed, crushed, sieved, and set aside.

[0044] Weigh 250g 20% of the wettable powder of erythoxystrobin for subsequent use (self-made) (equivalent to 50g of the active ingredient);

[0045] Mix the above-obtained active humi...

Embodiment 2

[0047]Example 2 Preparation of product 2 of the present invention

[0048] Get 1600kg of beet sugar factory alcohol waste liquid, leave standstill to clarify, obtain supernatant liquid, then described supernatant liquid is heated to 85 ℃ and carry out evaporative concentration, obtain concentrated liquid 350kg, in concentrated liquid, add nitric acid until the pH of concentrated liquid is 2, stand for activation at room temperature for 24 hours, then add ammonia water to adjust pH to 6.5 to obtain active humic acid solution, dry, pulverize and sieve the active humic acid solution to obtain active humic acid, about 150kg is for standby use.

[0049] Weigh 50kg of polyacrylamide (purchased from Renqiu Zhenghao Chemical Products Co., Ltd.) and 400kg of peat moss, respectively, and pulverize, sieve, and reserve.

[0050] Take by weighing 334g30% of the 30% fenoxystrobin WP for subsequent use (self-made) (the active ingredient is 100g);

[0051] The above-obtained active humic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com