Pneumatic tire and manufacturing method of pneumatic tire

A technology for a pneumatic tire and a manufacturing method, which is applied to pneumatic tires, tire treads/tread patterns, special tires, etc., can solve the problems of easy disconnection of conductive paths, influence of electrical performance, and insufficient connection of conductive rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0085] Hereinafter, examples showing the configuration and effects of the present invention will be described. Each performance of the tire was evaluated as follows.

[0086] (1) Rolling resistance

[0087] Rolling resistance was measured in accordance with the international standard ISO28580 (JISD4234), and evaluated using its reciprocal. Index evaluation was performed with the result of Example 1 taken as 100, and a larger value indicates better rolling resistance.

[0088] (2) Driving stability

[0089] The tires were mounted on real vehicles and the specified air pressure of the tires was established, and straight driving and cornering were carried out, and the evaluation was carried out through the driver's sensory experiment. Index evaluation was performed with the result of Comparative Example 1 as 100, and a larger value indicates better driving stability.

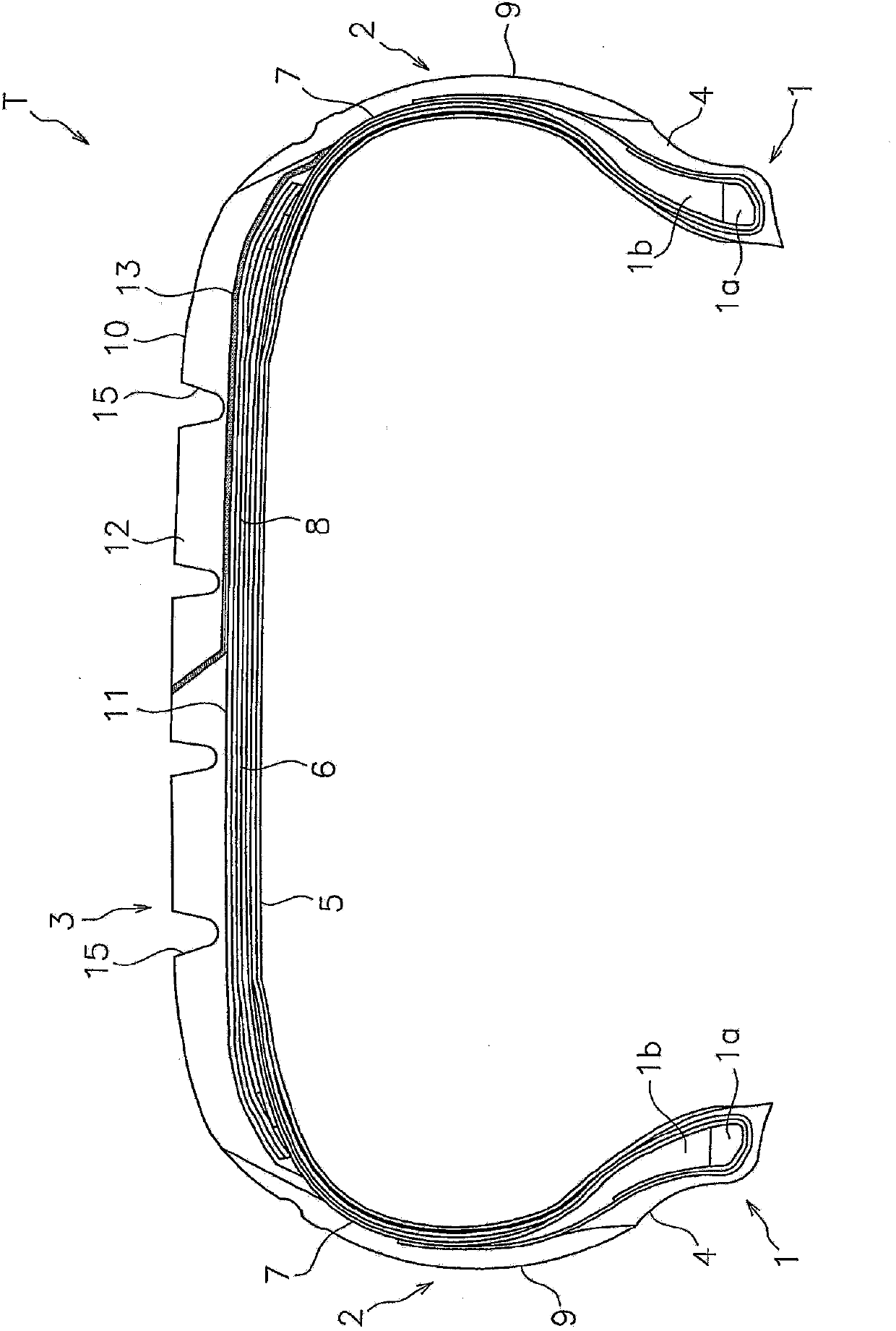

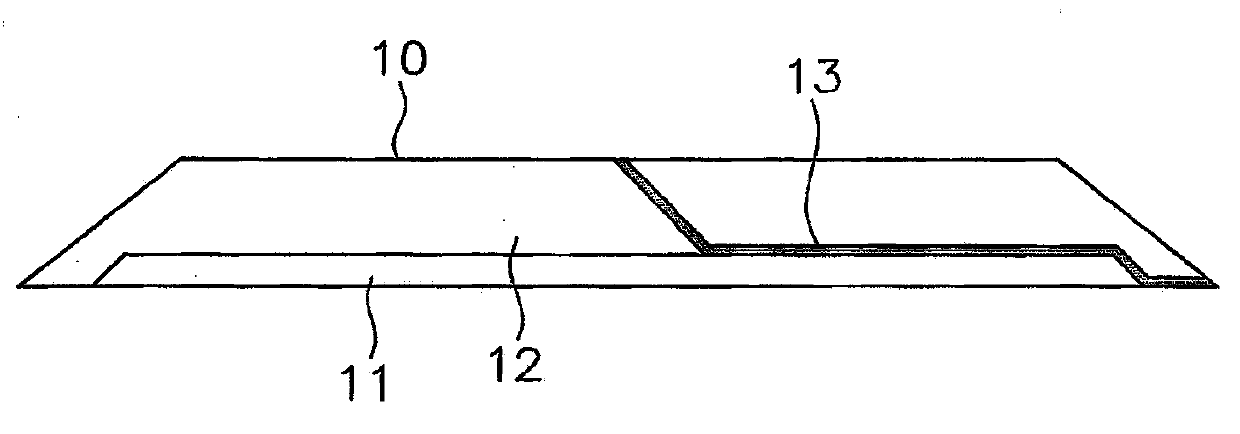

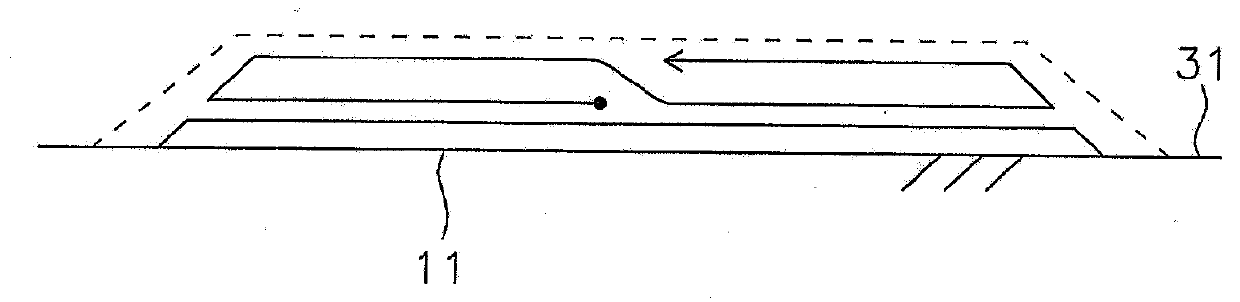

[0090] use Figure 4 , 5 The rubber belt shown is used to form a tread layer by the belt winding method, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com